Struggling with complex regulations for scale accuracy? Non-compliance can risk fines and recalls, making you anxious. Understanding these rules is the key to ensuring quality and peace of mind.

Yes, industries like pharmaceuticals and food have strict regulatory requirements for scale accuracy. These rules often demand specific error tolerances, such as ±0.1% of the full scale under Good Manufacturing Practices (GMP), and require regular, documented calibration schedules.

You know that rules exist, but navigating the specifics can feel like walking through a minefield. One wrong step could impact your entire production line, lead to audit failures, or even damage your company's reputation. The stakes are high, especially when product safety and quality are on the line. It's not just about having a scale; it's about having the right scale that performs correctly every single time. Let's break down exactly what these standards are and what they mean for your daily operations, so you can move forward with confidence.

What are the compliance standards for industrial scale accuracy?

Navigating the web of compliance standards for industrial scales feels overwhelming. Using a non-compliant scale, even by accident, puts your product quality and your entire operation at risk.

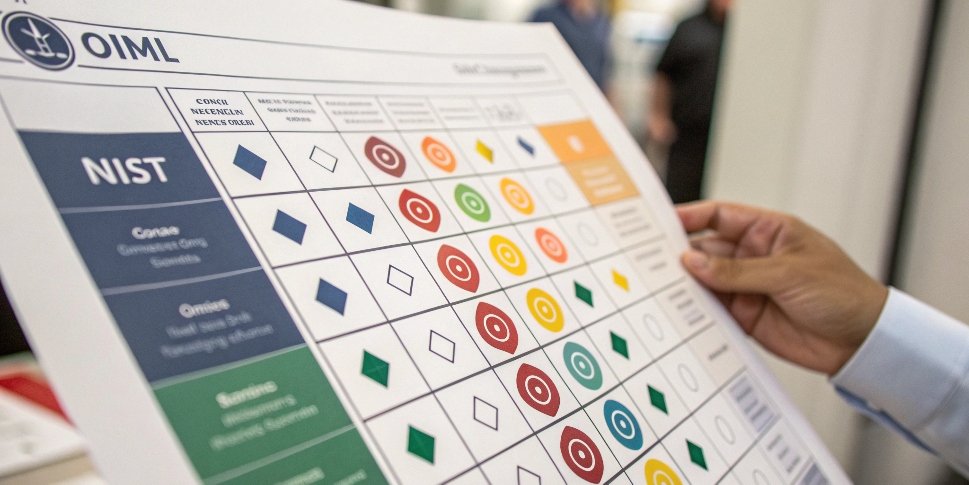

General compliance standards for industrial scale accuracy are set by global bodies like the OIML and national ones like NIST. These organizations define accuracy classes and testing procedures to ensure scales provide reliable and repeatable measurements for commercial and industrial use.

At the core of industrial scale compliance are standards that create a universal language for accuracy. The two most important organizations are the International Organization of Legal Metrology (OIML1) and, in the United States, the National Institute of Standards and Technology (NIST2). They establish the framework that most industry-specific regulations are built upon. They do this by creating "accuracy classes3." Think of these classes as tiers of precision. A scale's class tells you what kind of job it's suited for.

Here’s a simple breakdown of the most common classes we work with:

| Accuracy Class | Typical Use Case | Example Application |

|---|---|---|

| Class I | High-precision scientific weighing | Pharmaceutical formula development, analytical testing |

| Class II | Precious materials, detailed lab weighing | Gemstones, high-value chemicals, lab recipes |

| Class III | General industrial and commercial trade | Food packaging, logistics, batching ingredients |

| Class IIII | Rough, high-capacity weighing | Highway weighbridges, waste management |

As a manufacturer, we design our scales to meet the rigorous testing requirements for these classes. This ensures that when you select a Weigherps scale, you're starting with a piece of equipment built on a foundation of recognized, global standards.

Which regulations govern weighing equipment in the pharmaceutical industry?

In the pharmaceutical world, the smallest weighing error can have huge consequences. The fear of failing a Good Manufacturing Practices (GMP) audit because of non-compliant equipment is very real.

The primary regulations are Good Manufacturing Practices (GMP), as enforced by bodies like the FDA. GMP demands that scales are fit for purpose and regularly calibrated. For critical weighing, an accuracy error of no more than ±0.1% of the full scale is a common requirement.

For our clients in the pharmaceutical sector, GMP is the law of the land. These regulations are designed to ensure product safety, efficacy, and quality. When it comes to weighing, GMP requires that your instruments are not only accurate but that you can prove it. This means your scale must be "suitable for its intended use." A scale for weighing bulk excipients will have different requirements than an analytical balance for an active pharmaceutical ingredient (API)4.

Beyond GMP, the United States Pharmacopeia (USP)5, particularly Chapter <41>, provides specific guidelines on balance performance. Key operational requirements include:

- Accuracy: For critical processes, the error tolerance is often set at ≤ ±0.1% of the full scale (FS).

- Calibration: You need a strict, documented calibration schedule. For high-precision lab balances, this could be as often as every three months, with daily checks.

- Record Keeping: Every calibration and verification check must be logged with traceable information, including the date, the standard weights used, and any observed errors.

We help our pharmaceutical clients meet these demands by providing scales with the necessary precision and software features that simplify record-keeping for audits.

What standards must scales meet to be certified as "Legal for Trade"?

Selling products based on weight requires more than an accurate scale; it needs legal certification. Using a non-certified scale for commercial transactions can lead to serious legal penalties and force product recalls.

To be certified "Legal for Trade" (LFT), a scale must meet the strict requirements of legal metrology bodies, such as OIML R 76 internationally or NIST Handbook 44 in the US. This certification ensures accuracy, reliability, and tamper-resistance for fair commerce.

"Legal for Trade" (or LFT) is a term you'll encounter whenever a product's price is determined by its weight. This applies to everything from pre-packaged food at a supermarket to bulk materials sold by the ton. The goal of LFT regulations is to protect both the buyer and the seller by ensuring the weighing instrument is accurate and can't be easily manipulated.

Getting a scale LFT-certified involves a two-part process. First, the scale's design must receive a "Type Approval" or "Certificate of Conformance" from a recognized body. This confirms the model is capable of meeting the standards. Second, each individual scale sold for an LFT application must be inspected, verified, and sealed by a local weights and measures official.

Key requirements for LFT certification include:

| LFT Requirement | Description | Why It Matters |

|---|---|---|

| Type Approval | An authorized lab tests the scale design against strict standards. | Guarantees the model is fundamentally reliable and accurate. |

| Initial Verification | A service technician tests and validates your specific unit on-site. | Confirms the scale you bought performs correctly in your environment. |

| Sealing | Calibration controls are physically or digitally sealed. | Prevents unauthorized adjustments and builds consumer trust. |

We design many of our scales with these requirements in mind, ensuring they can pass the necessary evaluations to be certified Legal for Trade, giving you the confidence to use them in any commercial setting.

How do FDA requirements for scale accuracy impact food production?

Food producers face constant pressure to ensure product safety and label accuracy. An inaccurate scale can easily lead to inconsistent recipes, wrong nutrition labels, and unwanted attention from the FDA.

The FDA, through regulations like the Food Safety Modernization Act (FSMA) and GMPs, requires scales to be "of suitable accuracy." This means you must prove and document that your scales are routinely calibrated and precise enough for your specific processes, from recipes to net weight labeling.

In food production, the FDA6’s focus is on process control and consumer protection. While they might not always state a specific percentage for accuracy like in pharma, their requirement that equipment be "suitable for its intended use" is just as serious. Under FSMA, accurate weighing is a critical preventive control. It ensures recipe consistency, which is vital for product quality and for managing allergens. An error in weighing an ingredient like peanuts or soy could have severe safety consequences.

Furthermore, accurate declaration of net weight on packaging is mandated by the Fair Packaging and Labeling Act (FPLA). Inaccurate scales are a primary cause of net weight violations, which can lead to fines and mandatory recalls. I once worked with a client in the snack food industry who was struggling with this. By implementing daily calibration checks7 and using a scale with better resolution for their seasonings, they solved their consistency issues and ensured compliance. We advise all our food industry clients to implement robust daily verification procedures using certified weights and to maintain diligent records. This practice provides the proof of control the FDA requires.

Conclusion

In regulated industries like food and pharma, scale accuracy is not optional. It is a cornerstone of compliance, safety, and quality, ensuring your operations remain trustworthy and efficient.

-

Understand OIML's influence on scale compliance standards and how it affects your industry practices. ↩

-

Explore NIST's standards to ensure your scales meet the necessary accuracy and reliability for commercial use. ↩

-

Learn about accuracy classes to choose the right scale for your specific application and ensure compliance. ↩

-

Understand the unique scale requirements for APIs to ensure compliance and product quality. ↩

-

Learn about USP guidelines to ensure your scales meet the necessary performance standards in pharmaceuticals. ↩

-

Understand FDA requirements to ensure your food production scales meet safety and labeling standards. ↩

-

Find out the frequency of calibration checks needed to maintain scale accuracy and compliance. ↩

[…] You'll need a scale with a very small error margin, like ±0.1g or better. These are typically OIML Class II4 […]