Confused by weighing terminology? Using the wrong term can lead to costly mistakes. This guide clarifies the difference between a balance, scale, and weighing instrument for you.

A "weighing instrument" is the official term for any device that measures weight. A balance is for high-precision lab work, while a scale is for general, faster weighing. The key difference is precision and intended use.

I've been in the weighing industry for 18 years. I've seen clients lose money because they bought a "scale" when they needed a "balance." The terms seem interchangeable, but they are not. Understanding these differences is crucial for any business, especially for technical directors and purchasing managers who need to get specifications right. This knowledge is power. Let's break it down so you can avoid these common pitfalls and make choices that benefit your operations. Let me guide you through the specifics.

Is "weighing instrument" the official umbrella term for both scales and balances?

Unsure if "weighing instrument" is just a fancy word for a scale? This confusion can complicate technical specs and official purchase orders. Let's define the official term once and for all.

Yes, "weighing instrument" is the official and technical umbrella term. It includes any device designed to determine mass or weight. This covers both high-precision balances and general-purpose scales. Regulatory bodies and manufacturers use this term to cover the entire category.

I remember a project with a software company in Europe. Their purchase order specified a "high-precision scale," but their technical requirements matched a Class I analytical balance1. The ambiguity in terms nearly delayed their project by a month. This is why official terms like "weighing instrument" are so important. They provide a clear legal and technical foundation for everyone involved. In our industry, we follow international standards like those from the OIML2 (International Organization of Legal Metrology). These standards classify non-automatic weighing instruments (NAWIs) into different accuracy classes3. This system ensures that a buyer in Germany and a manufacturer in China are speaking the same language. It removes doubt and ensures you get exactly what you paid for.

Classification of Weighing Instruments

Here’s a simple breakdown of the accuracy classes to help you understand the landscape:

| Accuracy Class | Typical Application | Example Device |

|---|---|---|

| Class I | High-precision laboratory weighing, chemical analysis. | Analytical Balance |

| Class II | Precious metal weighing, pharmaceutical formulation. | Precision Balance |

| Class III | Commercial trade, logistics, industrial processes. | Most Industrial & Retail Scales |

| Class IV | Rough weighing where precision is not critical. | Certain Industrial Scales |

As a purchasing manager or technical director, referencing these classes in your documentation will make your requirements crystal clear.

What is the key functional difference that distinguishes a balance from a scale?

Do balances and scales seem the same to you? Choosing the wrong one means either overpaying for precision you don't need or getting data that is completely useless for your goals.

The key difference is precision and the underlying measuring principle. Balances use a comparison method for extremely high precision (milligrams), perfect for labs. Scales use sensors for direct weight measurement, offering speed and durability for industrial and commercial use with lower precision (grams to kilograms).

Think of a classic justice scale with two pans. That's the core idea of a balance. It compares an unknown mass to a known mass. Modern analytical balances use a sophisticated electromagnetic force restoration mechanism, but the principle of incredibly fine-tuned compensation remains. This makes them extremely sensitive to air currents, vibrations, and temperature changes. That's why you always see them inside glass enclosures in clean laboratory environments. On the other hand, most industrial scales you see, like the ones we manufacture at Weigherps, are workhorses. They use a load cell4, which is a sensor containing a strain gauge. When you place an object on the scale, the load cell deforms slightly, changing its electrical resistance. Our software then instantly converts this change into a weight reading. It's fast, robust, and perfect for a busy warehouse or production line where speed and durability matter more than sub-milligram accuracy.

Principle vs. Application

Here is a table to make the choice clearer:

| Feature | Balance | Scale |

|---|---|---|

| Principle | Compares mass (Leverage or EMFC) | Measures force (Strain Gauge/Load Cell) |

| Precision | Very high (e.g., 0.0001g) | Moderate to low (e.g., 1g - 1kg) |

| Environment | Controlled lab, stable surface | Industrial, commercial, home |

| Primary Use | Scientific analysis, formulation | Logistics, sales, general weighing |

| Durability | Fragile, sensitive | Robust, durable |

Are all modern digital scales technically considered weighing instruments?

The term "digital scale" sounds modern and official. But does the digital display automatically qualify it as a true "weighing instrument" in the technical sense? Let's check the facts.

Yes, absolutely. Any modern digital scale, from a simple kitchen scale to a complex industrial platform scale, is technically a weighing instrument. The term "weighing instrument" simply refers to the device's function—measuring weight—regardless of whether its display is analog or digital.

The shift from analog displays with a needle or dial to digital displays did not change the fundamental purpose of the device. It still measures weight. Therefore, every digital scale fits squarely under the "weighing instrument" umbrella. What did change is how we use the data from these instruments, and this is where it gets interesting for you as a software vendor or technical director. An old analog scale is a data dead-end. A modern digital weighing instrument from a partner like us is a gateway to information. We design our instruments with connectivity as a priority. Many of our industrial scales feature standard communication protocols like RS-232, USB, or Ethernet. We are also heavily invested in IoT-enabled weighing solutions5 that can transmit data wirelessly. This means our devices can seamlessly feed weight data directly into your management software, ERP systems, or custom applications. This eliminates manual data entry, reduces errors, and provides the real-time information your clients need to optimize their operations.

The "Digital" Advantage for Your Systems

It's not just about a digital number on a screen; it's about making that number actionable. This evolution allows your software to add immense value by interpreting, logging, and analyzing weight data to improve efficiency and profitability.

Besides scales and balances, what other devices are classified as weighing instruments?

Think scales and balances cover everything? Many specialized industries rely on other types of weighing instruments you may have never heard of. Let's explore these important hidden tools.

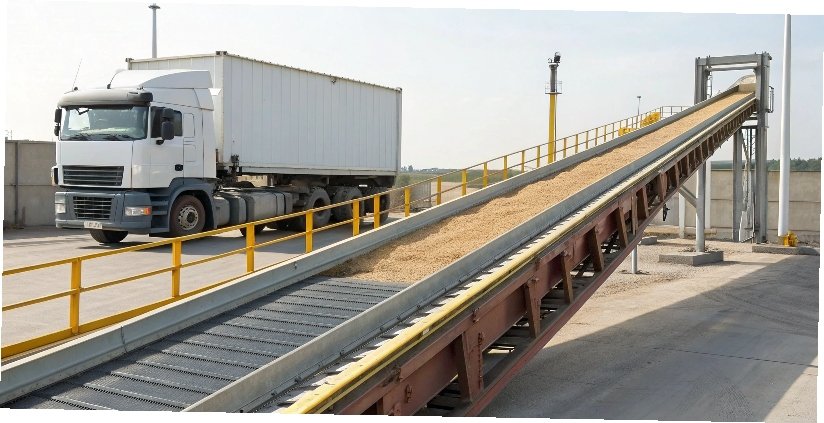

Beyond conventional scales and balances, the category of "weighing instruments" includes devices like individual load cells, weighbridges for trucks, belt weighers for continuous material flow, and checkweighers for production line quality control. Each is designed for a highly specific task.

At Weigherps, a huge part of our business is developing custom weighing systems for our clients. Often, the core component is simply the load cell. While it's usually part of a larger scale, a load cell on its own is a weighing instrument because it's the transducer that senses force. We often provide standalone load cells to clients who are integrating weighing functions into their own unique machinery. Another important area is dynamic weighing6. Not all weighing happens on a static platform. Think about a mine or a food processing plant. Belt weighers measure the weight of material moving along a conveyor belt, giving you a flow rate like tons per hour. Checkweighers are used on high-speed packaging lines to verify that every package is within its target weight range, automatically rejecting any that are over or under. These specialized instruments are essential for process automation and quality control.

Specialized Weighing Instrument Examples

| Instrument | Function | Common Industry |

|---|---|---|

| Load Cell | Senses force; the core of custom systems | OEM Machinery, Automation |

| Weighbridge | Weighs entire vehicles (trucks, rail cars) | Logistics, Waste Management |

| Belt Weigher | Measures material flow on a conveyor | Mining, Agriculture, Food |

| Checkweigher | Verifies package weight on a production line | Food & Beverage, Pharma |

These systems are where the synergy between hardware and software truly shines, creating automated, efficient, and intelligent operations.

Conclusion

Understanding the terms balance, scale, and weighing instrument ensures you choose the right tool. Precision, application, and data needs should guide your decision for optimal business results.

-

Learn about analytical balances and their critical role in high-precision laboratory settings. ↩

-

Explore the role of OIML in establishing international standards for weighing instruments. ↩

-

Explore the classification of weighing instruments to make informed decisions based on accuracy needs. ↩

-

Explore the function of load cells in weighing systems and their significance in automation. ↩

-

Explore the advantages of IoT-enabled weighing solutions for real-time data management. ↩

-

Learn about dynamic weighing and its applications in industries like food processing. ↩

[…] my line of work at Weigherps, we build industrial scales1 that must be precise under harsh conditions. The principles are the same for your home scale, just […]

[…] on proper user calibration. It's a non-negotiable step for anyone who needs precise results. An analytical balance3 doesn't just "know" what a gram is; you have to "teach" it by showing it a […]

[…] OIML5 R 76 is a global standard for the performance of weighing […]

[…] By embedding dozens of our load cells beneath the floor surface and connecting them to a central IoT gateway7, you can create a massive, distributed scale. The system collects data from each sensor and […]

[…] Electromagnetic Force Compensation (EMFC)1 […]