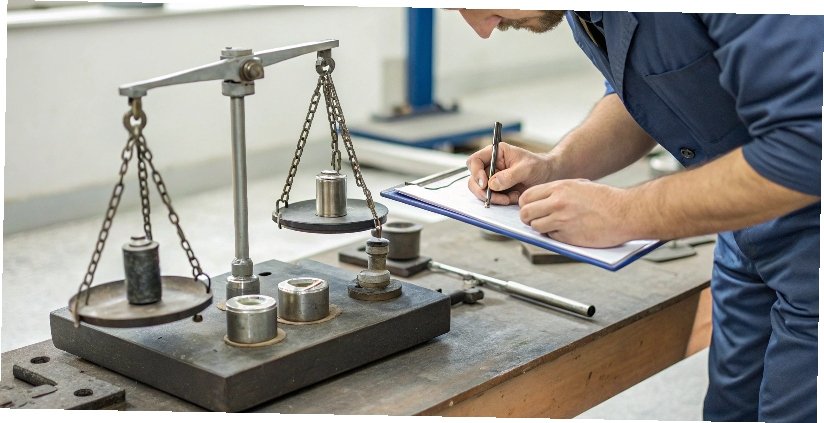

You see a scale with many decimal places and assume it's accurate. But this mistake could lead to costly errors. Understanding the difference between readability and accuracy is key for reliability.

A scale's high readability, or the smallest increment it can display, does not guarantee its accuracy. Accuracy refers to how close a measurement is to the true value. Factors like calibration and environment determine true accuracy, not just the display resolution.

I've seen it many times in my 18 years in this industry. A client buys a scale with an impressive-looking display, only to find their measurements are consistently off. This confusion is common, but it's important to clear it up. So let's dive into the details and separate what you see from what you get.

What is the difference between readability and accuracy in a weighing scale?

Are you using the terms readability and accuracy to mean the same thing? This common mistake can lead you to buy the wrong equipment for your needs. Let's clarify these two concepts.

Readability is the smallest division the scale's display shows (e.g., 0.01g). Accuracy is how close the displayed weight is to the object's actual weight. A scale can have high readability but poor accuracy if it's not calibrated or is affected by external factors.

Think of it like a car's speedometer. Readability is the ability to see your speed down to a single mile per hour. Accuracy is whether that speed matches how fast you are actually driving. A speedometer that shows "60.5 MPH" has high readability1, but if you're actually going 65 MPH, it's not accurate. In weighing, this distinction is critical.

Readability: The Display's Detail

Readability is simply the smallest increment a scale can display. It tells you nothing about how correct that number is. It's a measure of the display's resolution, not the scale's performance.

Accuracy: The Measurement's Truth

Accuracy is the degree to which a measurement conforms to the true, accepted value. It is the real-world performance of the scale. This is verified using traceable calibration2 weights—objects with a known, certified mass.

Here is a simple table to break it down:

| Feature | Readability | Accuracy |

|---|---|---|

| Definition | Smallest increment the display shows | Closeness of a measurement to the true value3 |

| Example | 0.001 g | ±0.002 g |

| Analogy | The number of seconds on a watch display | How close the watch is to the actual time |

| What it is | A specification of the display | A measure of total performance |

Can a scale with high readability be inaccurate, and if so, why?

You've picked a scale with a very precise display, expecting perfect results. Yet, your processes are still suffering from inconsistent weight measurements. Discover the hidden reasons why a high-resolution display can be misleadingly inaccurate.

Yes, a scale with high readability can be very inaccurate. This happens when the scale is not properly calibrated, is affected by environmental factors like temperature or vibration, or has poor internal components. The display might show many decimal places, but the measurement itself is far from the true value.

A scale is a sensitive instrument, and its final reading is the result of many factors working together. A fancy display can easily hide underlying problems that make the number on it incorrect. I once visited a client's facility where their expensive, high-readability scale was giving strange results. The problem? It was placed directly under an air conditioning vent. The high readability only made the constant fluctuations from the airflow more obvious.

The Problem of Poor Calibration

A scale's accuracy4 can drift over time due to wear and tear. Without regular calibration against a known standard, it will start giving wrong measurements. This systematic error5 means every single weighing result will be off, no matter how many decimal places it shows.

The Unseen Environmental Enemies

The environment plays a huge role in a scale's performance.

- Temperature: Even a small change of 1°C can cause measurement errors. This is why we test every one of our units for performance under different thermal conditions before it leaves our factory.

- Vibration: Nearby heavy machinery or even a lot of foot traffic can interfere with a sensitive load cell6.

- Air Drafts: An open door, a fan, or an HVAC system can apply enough force to alter a reading.

What factors besides readability determine a scale's true accuracy?

You're focusing only on the display's decimal places when buying a scale. This narrow focus means you might be overlooking the most critical performance specs. Let's look at the key technical factors that truly define accuracy.

A scale's true accuracy is determined by its calibration status, linearity, and repeatability. Linearity ensures accuracy across the entire weighing range, while repeatability ensures consistent results for the same object. These factors are far more important than display readability alone.

As manufacturers with 18 years of experience, we know that what's inside the scale matters most. The quality of the load cell, the electronics, and the software algorithm are the foundation of a reliable weighing system. When our clients ask for a custom solution, we focus on these core performance metrics first, because we know they are what deliver real business value.

Repeatability

Repeatability is the scale's ability to give the same result when you weigh the same object multiple times. If you place a 100g weight on the scale five times and get five different readings, the scale has poor repeatability7. This points to an unstable system and makes the instrument unreliable for any serious application.

Linearity

Linearity is the scale's ability to maintain its accuracy across its entire weighing capacity. Some scales might be accurate when weighing a 10g item but very inaccurate with a 1000g item. Poor linearity8 is often a sign of a low-quality load cell or poor software compensation.

How do you evaluate a scale's performance if the display resolution isn't enough?

The spec sheet looks great, but you need to be sure the scale performs in your facility. Buying based on numbers alone can be a gamble you can't afford. Here are practical steps to verify true performance.

Evaluate a scale's performance by conducting tests for repeatability and linearity using certified calibration weights. Check for drift by monitoring the reading over time in your actual work environment. Always ask the manufacturer for detailed specifications beyond readability, such as tolerance and linearity error data.

The best way to know if a scale is right for your needs is to test it under real-world conditions. This is why we encourage clients to discuss their specific application with us. We can help you identify the right performance criteria for your process and provide a solution that is truly fit for purpose, backed by our 12-month after-sales service guarantee.

Conduct Your Own Tests

Before committing to a large order, get a sample unit. Use certified test weights to check performance yourself.

- Repeatability Test: Place the same test weight on the center of the platform 10 times. Record each reading. The results should be very close to each other.

- Linearity Test: Use test weights at different points of the scale's capacity, for example, at 25%, 50%, and 100%. Check if the scale's error remains within its specified tolerance9 at each point.

Review All Documentation

A trustworthy manufacturer will provide more than a simple marketing brochure. Ask for a calibration certificate and a full technical data sheet. These documents will contain the real performance specifications, like linearity error and repeatability, that you need to make an informed decision.

Conclusion

High readability is just a number. True accuracy comes from quality components, regular calibration, and a stable environment. Focus on these factors for reliable results you can trust.

-

Understanding high readability helps you recognize its limitations in accuracy, ensuring better purchasing decisions. ↩

-

Learn about calibration's role in maintaining accuracy and preventing costly measurement errors. ↩

-

Understanding true value is crucial for evaluating the reliability of your measurements. ↩

-

Exploring accuracy definitions will clarify its importance in achieving reliable measurements. ↩

-

Understanding systematic error helps identify potential issues in measurement accuracy. ↩

-

Discover the importance of load cells in ensuring accurate and reliable measurements. ↩

-

Learn why repeatability is essential for consistent and reliable weighing results. ↩

-

Understanding linearity helps ensure accuracy across the entire weighing range. ↩

-

Understanding tolerance is vital for assessing the accuracy and reliability of measurements. ↩

[…] determines the precision of your measurements. Your application dictates the necessary readability4; don't pay for more than you […]

[…] the level of detail you can measure. Finer readability2 is needed for lab […]