Struggling to weigh items in high heat? Measuring inside an oven seems impossible. We have a solution for accurate weighing even in extreme temperatures, which I will share with you.

Yes, a load cell can be used in an oven. You must select a high-temperature model whose operating range exceeds the oven's maximum temperature. Also, ensure it has proper sealing, like an IP67/IP68 rating, to resist steam and moisture for reliable performance.

Using load cells in standard conditions is straightforward. However, when you introduce extreme heat, things get complicated. Many of our clients in the software and automation industry are looking to integrate weighing into processes like industrial baking1 or materials curing2. They need to know if their equipment can handle the heat. In my 18 years of experience, I've seen that success depends entirely on choosing the right components and installing them correctly. It is not a simple plug-and-play situation. You need to think about the entire system, from the sensor itself to the cables connecting it. Let's explore what it takes to get this right.

Are load cells suitable for use in high-temperature environments like ovens?

Worried that extreme heat will destroy your sensitive weighing equipment? You need reliable data from hot environments but fear equipment failure. We can explain which load cells are designed to handle the heat.

Yes, specific load cells are made for high temperatures. Standard load cells will fail quickly. But high-temperature models use special materials and construction to maintain accuracy and function reliably in environments like industrial ovens, often up to 250°C.

When we talk about high-temperature environments, we need to understand why a standard load cell fails. A regular load cell is usually made from aluminum or steel with adhesive-bonded strain gauges. When heated, these materials expand at different rates. This causes internal stress that creates false readings. The electronics inside can also drift or fail completely.

As a manufacturer, we solve this problem in a few ways.

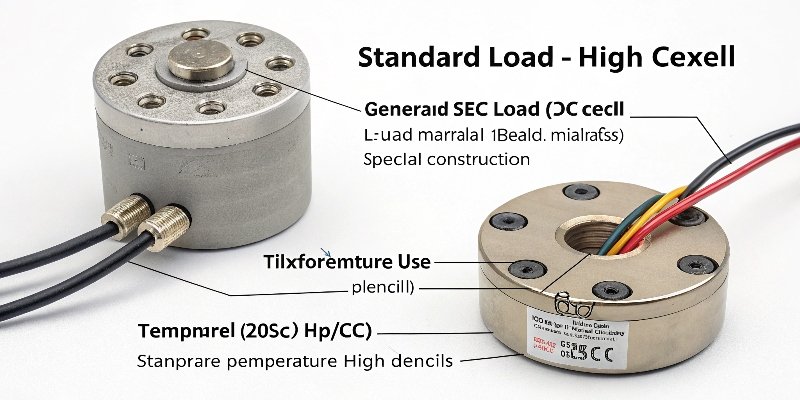

Materials and Construction

High-temperature load cells use special alloys3 that are much more stable across a wide temperature range. The adhesives used to bond the strain gauges are also formulated to withstand extreme heat without softening or degrading. All anufacturers' solutions are roughly as follows:

| Component | Standard Load Cell | High-Temperature Load Cell |

|---|---|---|

| Body Material | Aluminum / Alloy Steel | Stainless Steel / Special Alloys |

| Strain Gauge | Standard Foil Gauges | Special Alloy Foil Gauges |

| Adhesive | Epoxy-based (to ~80°C) | Ceramic Cement / High-Temp Resin |

| Internal Wiring | PVC-insulated | Teflon or Fiberglass-insulated |

Temperature Compensation

High-temperature models have advanced internal circuitry. This circuitry actively compensates for temperature changes, ensuring the output signal only reflects the weight, not the heat. This is a critical feature that separates them from standard models. Without it, you would not be able to trust the data coming from inside your oven.

What special considerations are needed when installing load cells in an oven?

Installing a load cell in an oven is not a simple task. You risk immediate failure if you do it wrong. Follow our expert installation tips to ensure your high-temperature load cell works perfectly from day one.

Key considerations include placement, cabling, and calibration. Position the load cell away from direct heat sources. Use high-temperature rated cables with protective sheathing like silicone. Finally, you must recalibrate the system at its operating temperature for accurate measurements.

Based on my experience helping clients, a successful high-temperature installation depends on careful planning. You cannot just place the load cell anywhere. Overlooking small details can lead to big problems later. At Weigherps, we always guide our partners through these crucial steps. Here is a breakdown of what you need to focus on.

Placement is Critical

Never install a load cell where it directly touches a heating element. The intense radiant heat can cause its temperature to spike far beyond the oven's ambient air temperature. We recommend using mounting brackets or standoffs. These create an air gap that protects the load cell from direct heat. It is also wise to place it in a part of the oven with the most stable and predictable temperature, if possible.

Cabling and Connections

The cable is often the weakest link. A standard PVC cable will melt and fail almost instantly in an oven. You must use a cable designed for high temperatures. We typically recommend cables with silicone or fiberglass jackets, as they can withstand the heat. Ensure the entire length of the cable inside the oven is rated for the environment.

Calibration in the Heat

A load cell calibrated at room temperature will not be accurate at 200°C. Temperature affects the mechanical properties of the sensor. Therefore, you must perform a system calibration at the actual operating temperature. You can do this by placing known weights on the scale inside the heated oven. This process, often guided by standards like ISO 33844, adjusts the system to provide true readings in the hot environment.

How does prolonged exposure to oven temperatures affect load cell accuracy and lifespan?

Are you concerned about long-term reliability? High heat can degrade equipment over time, leading to costly errors. It is important to understand the effects of prolonged heat to protect your investment and maintain accuracy.

Prolonged high temperatures can cause 'creep' and zero drift, which harms accuracy. It can also permanently damage the strain gauges and electronics, significantly shortening the load cell's lifespan. Using the correct high-temperature-rated model is essential to minimize these effects.

Heat is an enemy of precision electronics. Even a load cell designed for high temperatures will experience stress. Understanding these long-term effects helps you plan for maintenance and replacement. I have seen clients try to use standard load cells5 in hot environments, and they always fail. The issue is not just immediate failure, but slow and silent degradation that ruins process control.

Creep and Zero Drift

Creep is when the load cell's reading slowly changes even though the weight on it is constant. High temperatures accelerate this effect. Zero drift is when the load cell does not return to a perfect zero reading after a load is removed. Heat can cause the internal components to shift permanently, leading to this problem. A well-designed high-temperature load cell6 minimizes these effects, but regular calibration checks are still necessary to catch any changes over time.

Lifespan Reduction

Every component has a finite life. Heat acts as a catalyst that speeds up aging.

| Effect of Heat | Standard Load Cell | High-Temperature Load Cell |

|---|---|---|

| Material Fatigue | Rapidly loses elasticity, fails quickly. | Material is chosen for heat resilience, degrades slowly. |

| Adhesive Breakdown | Fails in hours or days, gauges detach. | Ceramic cement holds for thousands of hours. |

| Electronic Failure | Components fail above their rated temperature. | High-temp rated electronics last much longer. |

Ultimately, even a high-temperature load cell6 will not last forever. Its lifespan will be shorter than a similar load cell used at room temperature. That is why choosing a robust model from a reliable manufacturer like us is so important. It gives you the longest possible service life and the most stable performance.

What types of load cells are best for use inside ovens or other heated environments?

Choosing the right load cell can be confusing. The wrong choice means wasted money and failed projects. Let's simplify the options so you can pick the perfect high-temperature load cell for your application.

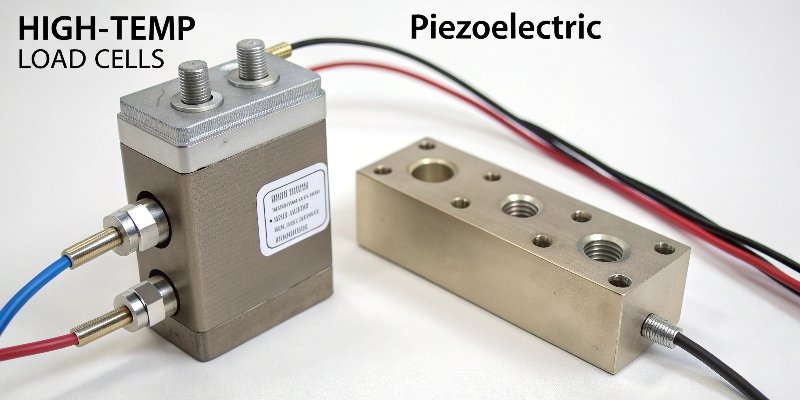

For high-temperature ovens, specially designed strain gauge and piezoelectric load cells are best. High-temp strain gauge models are great for static weighing, while piezoelectric types excel at dynamic force measurement in extreme heat. Always check the model's specific temperature rating.

The best type of load cell depends on what you need to measure. Are you weighing a static item, or are you measuring a dynamic force? At Weigherps, we help our clients select the right technology for their specific needs, ensuring they get cost-effective and reliable solutions.

High-Temperature Strain Gauge Load Cells

These are the most common choice for weighing applications in ovens. They work just like a standard load cell but are built with heat-resistant materials. They are ideal for static or slow-changing weight measurements. A perfect example is monitoring the weight of bread as it bakes to determine when it is done. They offer a good balance of cost and performance.

Piezoelectric Load Cells

These are not typically used for static weighing because their signal can drift over time. However, they are excellent for measuring dynamic forces in extreme temperatures. Imagine a hot-stamping or forging process inside a heated chamber. A piezoelectric load cell can measure the force of each impact with incredible accuracy, even at very high temperatures.

Here is a quick guide to help you choose:

| Load Cell Type | Best Use Case | Typical Temperature Range |

|---|---|---|

| High-Temp Strain Gauge | Static weighing (e.g., baking, curing) | -50°C to 200°C |

| Piezoelectric | Dynamic force monitoring (e.g., stamping) | -50°C to 250°C+ |

| Special Custom Designs | Unique applications, extreme environments | Varies by design |

When our clients come to us with a high-temperature weighing challenge, we start by asking about the application. By understanding their process, we can recommend a specific type and model that will provide accurate data reliably and for a long time.

Conclusion

In short, you can use load cells in ovens by choosing the right high-temp model, installing it correctly, and understanding the long-term effects, which will ensure accurate and reliable weighing.

-

Discover how accurate weighing impacts the quality and consistency of baked goods in industrial settings. ↩

-

Find out how load cells play a crucial role in the materials curing process for various industries. ↩

-

Find out about the materials that enhance the performance and durability of high-temperature load cells. ↩

-

Learn about ISO 3384 standards and their role in ensuring accurate load cell calibration. ↩

-

Explore the differences between standard and high-temperature load cells to make informed choices. ↩

-

Explore this link to understand the technology behind high-temperature load cells and their applications. ↩ ↩

Comments (0)