Are your current scales creating data bottlenecks? Manual data entry is slow and causes errors, preventing you from integrating weighing data into your smart systems. It's frustrating and inefficient.

Yes, modern industrial scales can connect to Wi-Fi, Ethernet, and 4G immediately after unboxing. These integrated PC scales are designed with flexible, built-in connectivity options, allowing them to seamlessly join your existing IT infrastructure without needing extra hardware or complex configurations.

This instant connectivity is a game-changer. It’s not just about getting rid of a few cables; it’s about transforming your scale from a standalone device into a smart, active node within your entire operation. This simple change opens up a world of possibilities for automation, data analysis, and efficiency. But what are the specific options you can get, and how do they really change your day-to-day workflow? Let’s dive in and explore what this means for your business.

What Connectivity Options Are Available with Scales Right Out of the Box?

Choosing a new scale can feel overwhelming with all the technical jargon. You worry that picking the wrong model will leave you with compatibility issues or force you to buy expensive adapters.

Scales today come with a variety of built-in connectivity choices. The most common are Wi-Fi for wireless freedom, Ethernet for a stable wired connection, and 4G for remote operations. This means you can choose the exact setup you need from the very beginning.

When we design our integrated PC scales, our primary goal is to give you choices. You shouldn't have to change your workflow to fit a scale; the scale should fit your workflow. I remember working with a logistics company that had a massive warehouse with Wi-Fi blackspots. For their fixed packing stations, we recommended Ethernet for maximum reliability. For their mobile inventory carts, Wi-Fi was the obvious choice. And for a temporary outdoor receiving area they set up, the 4G-enabled scales were perfect, sending data directly to their cloud system without needing any local network infrastructure. This kind of flexibility is crucial.

Choosing the Right Connection for Your Needs

Each connectivity option serves a different purpose. Understanding their strengths helps you build a more robust and cost-effective weighing system1. Our approach allows you to select only the modules you need, so you aren't paying for features you'll never use.

| Connectivity | Best Use Case | Pros | Cons |

|---|---|---|---|

| Ethernet | Fixed stations, secure networks | Highly stable, fast, secure | Limited mobility, requires cabling |

| Wi-Fi | Mobile carts, flexible layouts | Wireless, easy to set up | Signal can be inconsistent |

| 4G | Remote sites, outdoor use | Works anywhere with cell service | Requires a data plan, can be slower |

By offering these as modular options, we empower you, our partner, to create the perfect hardware solution for your software.

How Do Scales with Built-in Wi-Fi, Ethernet, and 4G Enhance Operations?

Is your team wasting valuable time writing down weights and manually typing them into a computer? This outdated process is not only slow but also a major source of costly human errors.

Built-in connectivity completely automates the data capture process. These scales seamlessly integrate with your software (like ERP, WMS, or your own custom platform), enabling real-time data transfer, remote monitoring of operations, and a significant boost in overall efficiency and accuracy from day one.

The transformation from a manual to an automated workflow2 is immediate. I once visited a client in the food processing industry. Their workers were weighing batches of ingredients, writing the weights on a clipboard, and then walking to an office PC to enter the data into a spreadsheet. After we replaced their old scales with Wi-Fi-enabled models, the process changed entirely. Now, the weight of each batch is sent directly to their inventory management system3 the moment it's measured. The system instantly confirms the batch is correct or flags a deviation.

From Manual to Automated Workflow

This automation enhances operations in several key areas. First, it enables real-time data transmission4. At a shipping station, for example, the scale can send the exact package weight to your shipping software, which then instantly generates the correct shipping label. This eliminates keystroke errors and speeds up the entire fulfillment process. Second, it allows for remote monitoring5. A production manager can sit in their office and view a live dashboard showing the output and performance of every weighing station on the factory floor. Finally, it simplifies software integration6. As a software provider, you know that easy integration is critical. Our scales communicate using standard protocols, making it simple for your applications to receive weight data without complex custom development. This allows you to focus on adding value with your software, not on solving hardware communication problems.

What Are the Benefits of Immediate Network Connectivity in Modern Scales?

Are you concerned about the expense and hassle of upgrading your weighing equipment? Sticking with old, disconnected scales means you're falling behind competitors and missing out on valuable business insights.

Investing in scales with immediate connectivity provides a clear and rapid return. The benefits go far beyond convenience, leading to lower costs, fewer errors, and access to data for smarter decision-making.

The core benefits of out-of-the-box connectivity are efficiency and accuracy, which directly impact your bottom line. I've seen it happen time and again. A client in the parts manufacturing sector was struggling with inventory discrepancies. After upgrading to networked scales in their warehouse, their real-time inventory count became 99.9% accurate. They eliminated costly emergency orders and reduced the time spent on manual stock-takes by hundreds of hours per year. The investment paid for itself in less than six months.

Tangible Returns on Your Investment

The move to connected scales delivers measurable results across your business. You aren't just buying a new piece of hardware; you're upgrading your entire operational capability. Here's a breakdown of the direct benefits:

- Reduced Labor Costs: Automating data entry frees up your staff to focus on more valuable tasks instead of acting as human data couriers.

- Drastically Improved Accuracy: By eliminating manual transcription, you prevent costly errors related to shipping, billing, and inventory. This also leads to higher customer satisfaction.

- Enhanced Throughput: Processes like receiving, packing, and quality control7 become faster and smoother, allowing you to handle more volume without increasing headcount.

- Real-Time Data for Better Decisions: With live data from every weighing point, managers can spot trends, address production issues instantly, and make informed choices to optimize workflows.

These benefits combine to give your company a strong competitive edge. You become more agile, more efficient, and more responsive to the market.

How Can Integrated Connectivity in Scales Improve Data Transmission and Analysis?

You collect a lot of weighing data, but is it stuck in isolated spreadsheets? This disconnected data is always out of date, making it nearly impossible to use for meaningful, proactive analysis.

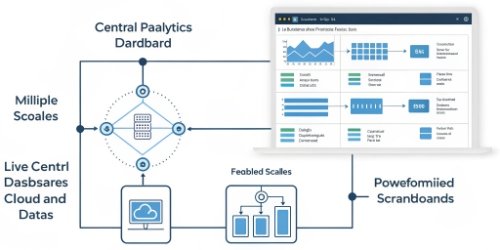

Integrated connectivity solves this by streaming clean, structured data in real-time. It sends information directly from the scale to your central databases or cloud platforms, creating a live data pipeline for powerful analytics.

For you as a software vendor, this is where our partnership truly shines. We provide the reliable hardware foundation that powers your analytics solutions. Our integrated PC scales are more than just scales; they are edge computing devices8. They can pre-process data, format it correctly, and send it securely using standard web protocols. This means your software application can easily "listen" for data from our scales with minimal development effort from your team. We handle the hardware and data transmission, so you can focus on creating stunning dashboards and powerful analytical tools for your customers.

Powering Your Software with Live Data

Imagine the solutions you can build when every scale in your customer's operation is a live data source. Our scales can transmit data in developer-friendly formats like JSON or XML over protocols like MQTT or HTTP APIs. This seamless flow of information unlocks advanced capabilities:

- Live Performance Dashboards: Create dashboards that visualize production line efficiency, a packer's speed, or a warehouse's total throughput in real time.

- Predictive Analytics: Use historical weight data to build models that predict when raw material stock will run low or when a machine needs maintenance.

- Automated Quality Control: Your software can automatically flag and alert staff when a product weighs more or less than its specified tolerance, preventing defective items from ever leaving the factory.

As your manufacturing partner, we provide the robust, certified hardware and expert technical support you need. We empower you to deliver innovative, data-driven solutions that solve your customers' biggest challenges.

Conclusion

Modern scales with built-in connectivity are essential tools for any business. They drive efficiency, guarantee accuracy, and provide the real-time data you need to compete and grow.

-

Discover strategies to build a cost-effective weighing system tailored to your needs. ↩

-

Discover how an automated workflow can enhance efficiency and reduce errors. ↩

-

Explore how an inventory management system can streamline your operations. ↩

-

Discover effective data transmission methods to enhance operational efficiency. ↩

-

Explore how remote monitoring can provide insights into your operations from anywhere. ↩

-

Learn best practices for seamless software integration to enhance functionality. ↩

-

Learn about the importance of quality control in maintaining product standards. ↩

-

Explore how edge computing devices can enhance data processing and analysis. ↩

Comments (0)