Your process demands precision, but your scale gives inconsistent readings. This fluctuation could be caused by the room's temperature, leading to costly errors and waste. Understanding this impact is the first step to control.

Yes, temperature directly impacts a scale's accuracy. As temperatures change, the internal components of a scale, especially the load cell, expand or contract. This physical change causes measurement errors like zero drift and altered sensitivity, leading to inaccurate weight readings.

This isn't just a minor inconvenience; for businesses that rely on precise measurements for recipes, shipping, or quality control, these small errors can add up to significant financial losses. We have seen this happen with clients time and time again. But once you understand exactly how heat and cold interfere with the weighing process, you can take simple steps to protect your results and your bottom line. Let's look closer at how this works.

How does temperature affect accuracy?

You see the numbers on your scale drifting but cannot pinpoint the cause. This unreliability is frustrating. The answer is not in the software but in the physics of your scale's most critical components.

Temperature changes the physical size and properties of a scale's internal load cell. High temperatures can cause it to expand, leading to lower readings. Colder temperatures cause contraction, which can lead to higher readings. This results in inconsistent and unreliable measurements over time.

In my 18 years of experience manufacturing industrial scales, I’ve seen this firsthand. The core of the problem lies within the strain gauge load cell1, the heart of any electronic scale. It’s an incredibly sensitive piece of technology that works by measuring a tiny deformation when a load is applied. Temperature changes introduce errors in three main ways.

Key Temperature Effects

- Zero Drift: The most common issue is "zero drift2." A scale is calibrated to read "zero" with nothing on it. As temperature rises, the metal in the load cell expands slightly. The scale interprets this expansion as a small amount of weight, so the zero point drifts. For example, a 10°C change can cause a zero drift of up to 0.028% of the scale's full capacity.

- Sensitivity Change: Temperature also affects the material's elasticity, known as its elastic modulus. In warmer conditions, the material becomes slightly softer, flexing more for the same weight, which can cause the scale to read low. In the cold, the material gets stiffer, leading to higher readings.

- Linearity Disruption: Ideally, a scale's output should be perfectly linear. Doubling the weight should exactly double the reading. Temperature fluctuations can disrupt this relationship, making the scale less accurate at different points in its weighing range.

Here is a simple table showing how significant the errors can be without proper compensation technology.

| Temperature Range | Typical Error | Impact Level & Recommendation |

|---|---|---|

| 0°C to 40°C | ≤±0.1% (with compensation) | Negligible. Most professional scales operate well here. |

| 40°C to 60°C | ±0.5% to 1% | Significant. Requires frequent recalibration. |

| Above 60°C | Potential sensor failure | Requires special high-temperature scales3. |

This is why we build advanced temperature compensation circuits4 into our scales. A small, built-in sensor measures the ambient temperature and adjusts the readings in real-time to counteract these physical effects, ensuring you get an accurate weight every time.

What might interfere with scale accuracy?

You have controlled the temperature, but errors still appear. It feels like invisible forces are sabotaging your measurements. Let's uncover these other hidden culprits that can throw off your scale's precision.

Beyond temperature, many factors can interfere with accuracy. These include physical forces like air drafts and vibrations from nearby machinery, and electrical issues like radio frequency interference (RFI) from phones or two-way radios. Even being on an unlevel surface will cause errors.

A scale is a sensitive instrument, and its environment is just as important as its internal components. From our experience helping clients set up their weighing stations, we have identified several common sources of interference. Thinking about these can help you create a more stable and reliable weighing process.

Environmental Factors

The world around your scale has a direct impact.

- Air Drafts: A light breeze from an open door, an HVAC vent, or even a person walking by can exert force on the scale's platform, causing readings to fluctuate. This is especially true for high-precision scales measuring in grams or milligrams.

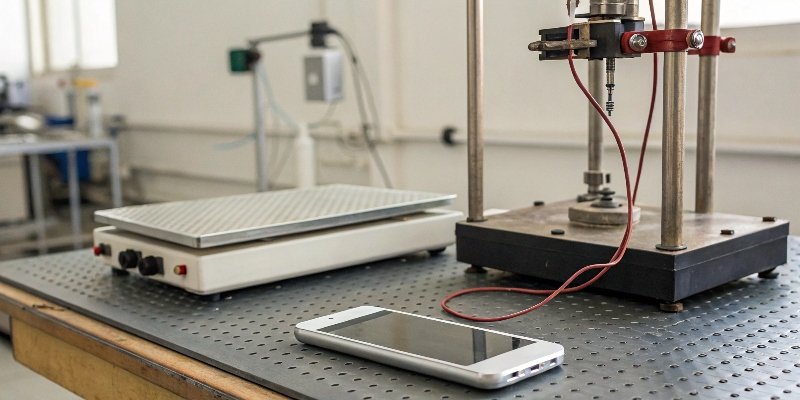

- Vibrations: Is your scale near a large motor, a generator, or a high-traffic forklift path? The vibrations traveling through the floor can create "noise" in the readings, making it impossible for the scale to settle on a stable weight. A sturdy, isolated weighing table is often the solution.

- Static Electricity: In dry environments, static buildup on plastic containers or materials can exert a pull or push on the weighing pan, leading to incorrect readings. Using an anti-static device can help neutralize this effect.

Operational Factors

Sometimes, the issue is how the scale is being used.

- Uneven Surfaces: A scale must be perfectly level to work correctly. All modern industrial scales have leveling feet and a bubble indicator for this reason. If the scale is tilted, the force of gravity is not applied directly downward on the load cell, causing an inaccurate reading. We always tell our clients to check the level bubble before use.

- Radio Frequency Interference (RFI): Strong radio signals from cell phones, walkie-talkies, or powerful electrical equipment can interfere with the scale's sensitive electronics. This can cause the display to drift or show random numbers. It's best to keep such devices away from the weighing area.

Creating a "safe zone" for your scale—free from drafts, vibrations, and RFI—is crucial for getting the repeatable, accurate results you depend on.

Do scales work in the cold?

You need to weigh products in a refrigerated warehouse or a cold climate. You worry the freezing temperatures will damage your equipment or, worse, give you false data. The good news is, scales can work in the cold.

Yes, many scales are designed to function in cold environments, but you must choose the right one. Standard scales will lose accuracy as low temperatures make components stiff, cause condensation inside the electronics, and drastically reduce battery life. Look for scales with a wide operating temperature range.

Working in cold environments presents unique challenges that go beyond the basic temperature effects we discussed earlier. As a manufacturer, we design and test scales specifically for these conditions, because a standard warehouse scale often fails in a refrigerated or outdoor winter setting. Here is what you need to consider.

Challenges of Cold Environments

- Component Brittleness: At very low temperatures, some materials can become brittle. This is less of a problem for the load cell itself, but it can affect plastic housings, cables, and other components, making them more susceptible to damage from impacts.

- Slower Electronics: The liquid crystals in an LCD display can slow down in the cold, causing the numbers to update sluggishly. This can make the scale difficult to use. We often recommend scales with brighter LED displays for cold applications, as they are not affected.

- Condensation: This is the biggest enemy. When you bring a cold scale into a warmer, more humid area, condensation can form inside the housing and on the electronic circuit boards. This moisture can cause short circuits and permanent damage. Scales with a high IP rating5 (like IP67 or IP68) are sealed against moisture ingress, protecting them from this exact problem.

- Battery Performance: If you are using a battery-powered scale, be aware that cold temperatures can reduce battery capacity by 50% or more.

From our experience, a scale with proper temperature compensation, like the type we engineer at Weigherps, can maintain excellent accuracy across a wide temperature spectrum. For instance, a well-designed balance with compensation can maintain an error of less than 0.05% in temperatures ranging from -10°C to 50°C. That is the kind of reliability you need for tough conditions.

Why do I get different readings on different digital scales?

You weigh the same sample on two different scales and get two different results. This inconsistency is frustrating and makes you question which scale you can trust. Let's look at why this happens.

Different readings on different scales are common. The variance comes from differences in manufacturing quality, sensor technology, calibration accuracy, and the scale's condition. A high-quality, properly calibrated scale will always give a more reliable result than a cheaper, uncalibrated one.

As a manufacturer, we live in a world of precision and tolerances. The reality is that no two scales are perfectly identical, but the goal is to make them as close as possible. When you see a difference in readings, it usually comes down to one of four areas.

The Four Pillars of Consistency

- Calibration: This is the most important factor. Calibration is the process of adjusting a scale to match a known, certified weight. If one scale was calibrated a year ago with a rusty weight and the other was calibrated yesterday with a certified one, their readings will differ. We recommend our clients calibrate their scales regularly, especially if they are moved or the temperature changes significantly.

- Quality of Components: The load cell is the heart of the scale. A high-end load cell made with superior materials and engineering will provide better repeatability (getting the same result every time you weigh the same object) and linearity than a low-cost one. This is where you truly get what you pay for. Better components result in a more trustworthy instrument.

- Resolution vs. Accuracy: Don't confuse a scale's display resolution with its accuracy. A scale might show a weight to three decimal places (e.g., 10.001g), but its actual accuracy might only be ±0.01g. A cheaper scale may have a high resolution but low accuracy, making it seem more precise than it is.

- External Factors: As we've discussed, the environment matters. If one scale is on a wobbly cart and the other is on a solid granite block, you will get different results. A slight incline or a breeze affecting one scale but not the other will also cause discrepancies.

To ensure consistency, always use a high-quality scale from a reputable manufacturer, place it on a solid, level surface, and calibrate it regularly with certified weights. This is the only way to trust the numbers you see.

Conclusion

Temperature and the surrounding environment critically affect scale accuracy. For reliable results, you must control for these factors, perform regular calibrations, and choose equipment designed for your specific operating conditions.

-

Learn about the core component of scales that affects accuracy and reliability. ↩

-

Discover how zero drift can lead to significant measurement errors. ↩

-

Learn about specialized scales designed to function accurately in extreme heat. ↩

-

Find out how these circuits help maintain accuracy despite temperature changes. ↩

-

Find out how IP ratings protect scales from moisture and enhance durability. ↩

[…] the scale, certain features on the box indicate better quality. Look for any mention of "temperature compensation6." This means the scale has internal circuits designed to minimize the effect of temperature […]

[…] 56 mph, or are you really going 53 mph? Accuracy is a broader concept, a combination of several performance factors2 that we will discuss next. A scale is accurate if its reading consistently matches the true weight […]

[…] it's fully protected. If you're working in extreme temperatures, you'll need a scale with special high-temperature sensors5. For hazardous areas with flammable gases or dust, you must use an ATEX-certified explosion-proof […]