Struggling to find the right load cell? A wrong choice can lead to inaccurate measurements and costly failures. But understanding a few key factors makes the selection process straightforward.

To find the best load cells, you must evaluate them on four key criteria: load capacity, required accuracy, environmental conditions, and the specific sensor type needed for your application. Matching these elements to your business needs ensures you get a reliable and cost-effective solution.

Choosing a load cell might seem complex with all the technical jargon out there. However, it doesn't have to be a guessing game. As someone who has been in the industrial weighing1 business for 18 years, I've seen how the right component can revolutionize an operation. The secret is to break down the decision into manageable steps. By focusing on the right questions, you can move from uncertainty to confidence, ensuring the load cell you select is a perfect fit for your system. Let's dive into how you can do just that.

How do you choose the right load cell?

Choosing a load cell feels overwhelming with so many technical specs. A mistake could mean buying a component that fails quickly or gives wrong data, ultimately wasting your money.

To choose the right load cell, match its capacity to your maximum load plus a safety margin. Then, select an accuracy level based on your application's sensitivity and ensure the unit's environmental protection (like IP rating) is sufficient for its operating conditions.

When you get down to the details, choosing a load cell is about three core elements. First, you need to match the load capacity2. For static weighing, like a storage tank, I always recommend choosing a load cell with a capacity that's 120% to 150% of your maximum expected weight. This gives you a safe buffer. For dynamic loads, like a crane scale where forces can spike, you need a much higher safety margin3, sometimes up to 300%. Next is accuracy. A lab or medical device needs incredibly high precision, but for most industrial tasks, a standard accuracy class is perfectly fine and more cost-effective. Finally, consider the environment. A load cell in a dry, clean room has different needs than one in a wet, dusty factory.

Here's a simple table to guide you:

| Factor | High-Demand (e.g., Lab) | Standard Industrial (e.g., Factory) |

|---|---|---|

| Safety Overload | 120% of Max Load | 150% of Max Load (static) |

| Accuracy (FS) | 0.01% - 0.001% | 0.1% - 0.01% |

| Environment | Controlled, IP54 | Wet/Dusty, IP67/IP68 |

How to check if a load cell is good?

You've ordered a load cell, but how can you be sure it's high-quality? A hidden fault can go unnoticed until it causes a major disruption in your production line.

A good load cell has stable technical specifications, such as a sensitivity of 2-3mV/V and low non-linearity error (≤0.03% FS). Always verify its quality by checking for a calibration certificate and asking about the warranty, which should be at least 12 months.

I once had a client whose production line was yielding inconsistent batches. They couldn't figure out why. After checking their system, we found the issue was with their load cells. The supplier hadn't provided a calibration certificate4, and the cells were drifting with temperature changes. A good load cell is proven by its data. The first thing you should look at is its sensitivity, which is typically around 2.0 or 3.0 mV/V. This tells you how much electrical signal it outputs for a given weight. Next, check the non-linearity error5, which should be very low—ideally less than 0.03% of its full scale. This ensures it's accurate across its entire weighing range. Finally, temperature drift6 is critical. A quality load cell should barely be affected by temperature changes. As a manufacturer, we provide a full report and a 12-month warranty with every unit because trust is built on verifiable performance.

Key Quality Indicators

- Sensitivity: Should be stable, typically 2-3mV/V.

- Non-linearity Error: Must be minimal, ≤0.03% FS is a good standard.

- Zero Temp Drift: Look for ≤0.01%/℃ to ensure stability.

- Documentation: Always demand a calibration certificate and warranty.

Which company load cell is best?

The market is crowded with load cell manufacturers, making it hard to know who to trust. Choosing a lesser-known brand feels risky, but established names can be very expensive.

The "best" company is the one whose products fit your specific application. For general industrial weighing, our Weigherps Z6 series is a cost-effective choice. For high-frequency dynamic measurement, Kistler is an expert. For hazardous environments, WIKA offers robust hydraulic options.

The best load cell isn't about the brand name; it's about the right tool for the job. Different technologies are designed for different challenges. The most common type is the strain gauge load cell7, which is the workhorse of industrial weighing. They are perfect for platform scales, hoppers, and tank weighing. This is our specialty at Weigherps, where we focus on creating durable and reliable models like our Z6FD1. However, if your application involves measuring rapid, dynamic forces like in a crash test, a piezoelectric load cell8 from a company like Kistler would be a better choice. Their sensors can capture impacts that a strain gauge might miss. For an explosive atmosphere where any spark is a danger, you can't use electronics. In that case, a hydraulic load cell9, like those from WIKA, is the safest and most reliable option.

| Load Cell Type | Typical Application | Recommended Model Example |

|---|---|---|

| Strain Gauge | Platform Scales, Tank Weighing | Weigherps Z6FD1/3 |

| Piezoelectric | Dynamic Impact Measurement | Kistler 9321B |

| Hydraulic | Explosive/Hazardous Areas | WIKA C-16 Series |

How do you size load cells?

Incorrectly sizing a load cell is one of the most common and costly mistakes. An undersized cell will fail, while an oversized one won't give you the accurate readings you need.

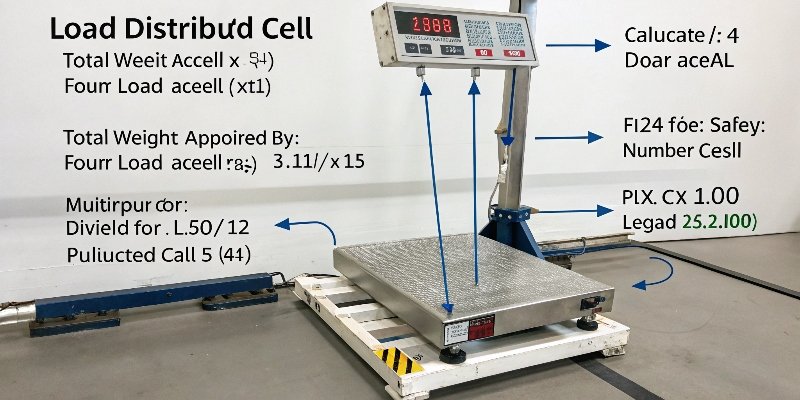

To size a load cell, first calculate the total weight your structure will support. Divide that weight by the number of load cells you'll use, and then multiply by a safety factor of 1.2 to 1.5 to determine the required individual capacity.

Sizing a load cell is a simple but critical process. Let’s walk through it. First, you need to know your total weight. This includes the weight of the scale or tank itself (the dead load) plus the maximum weight of the product you will be weighing (the live load). Add these two together to get your maximum load10. Next, you need to divide this total load by the number of support points. For example, a square platform scale with a load cell at each corner has four support points. So, you'll divide your total load by four. Finally, and this is a step people often forget, apply a safety factor. This protects the load cell from unexpected overloads or shock loading. A safety factor of 1.5 (or 150%) is a good rule of thumb for most static weighing applications. That final number is the minimum capacity you need for each load cell.

Sizing Formula

Required Capacity = (Total Load / Number of Cells) × Safety Factor (e.g., 1.5)

Conclusion

Choosing the right load cell means matching its capacity, accuracy, and type to your specific needs. Do this, and you’ll ensure a reliable, long-lasting, and cost-effective weighing solution.

-

Explore best practices to enhance accuracy and efficiency in industrial weighing. ↩

-

Understanding load capacity is crucial for selecting the right load cell for your application. ↩

-

A safety margin is essential for preventing overload; find out how to calculate it effectively. ↩

-

A calibration certificate ensures the accuracy and reliability of your load cell. ↩

-

Understanding non-linearity error helps you assess the accuracy of load cells. ↩

-

Temperature drift can impact measurement accuracy; learn how to mitigate its effects. ↩

-

Strain gauge load cells are widely used; discover their benefits and applications. ↩

-

Piezoelectric load cells are ideal for dynamic measurements; explore their unique features. ↩

-

Hydraulic load cells are crucial for hazardous environments; learn when to choose them. ↩

-

Understanding maximum load helps in selecting the right load cell for your needs. ↩

[…] remember the first time I saw '2.0 mV/V1' on a spec sheet. It looked like just another number. But, as I learned over 18 years in this […]

[…] standard steel load cells. Once we switched them to scales with stainless steel bodies and sealed, IP68-rated load cells4, their problems […]