Choosing the right scale feels complicated. The wrong choice leads to bad data and wasted money. Understanding a few key points makes the decision simple and ensures you get it right.

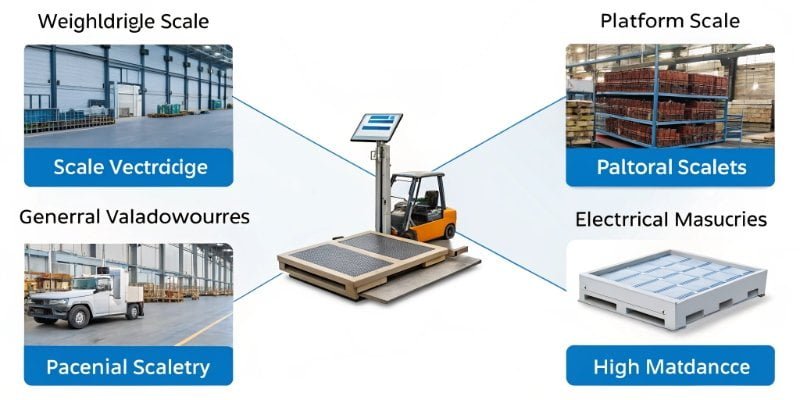

The best weighing option depends on your specific task. For heavy loads like trucks, you need a weighbridge. For factory goods, a platform scale works best. For precise lab measurements, you need a balance. Matching the scale to the application is key.

It's about more than just picking a big scale for big things and a small scale for small things. To really find the perfect fit, we need to look closer at what you're weighing, how precise you need to be, and how you plan to use the data. In my 18 years in this industry, I've seen that getting this first step right saves countless headaches down the road. Let's break down what you need to know to make a smart choice.

How do you choose the right type of scale for a specific application?

You have a job to do, but countless scales seem available. Picking the wrong one means your workflow suffers and your data can't be trusted, which directly hurts your business.

To choose the right scale, match it to your application. Use a weighbridge for vehicles, a platform scale for warehouse pallets and general-purpose industrial weighing, and an electronic balance for high-precision laboratory or jewelry measurements. The application always dictates the technology.

Choosing the right scale starts with understanding the main categories and where they fit. I've worked with clients across countless industries, and it almost always boils down to one of three types. Think of it as choosing the right tool for the job. You wouldn't use a hammer to turn a screw. It's the same with scales. Each type is built with a specific purpose, core technology, and accuracy level in mind. As a software provider, knowing this helps you advise your clients and ensure the hardware you're integrating with provides the data your system needs.

Here’s a simple breakdown I use to help my partners:

| Device Type | Typical Application | Core Working Principle | Typical Accuracy |

|---|---|---|---|

| Electronic Weighbridge | Weighing trucks, cargo containers, heavy logistics | Bridge / Column load cells under a steel deck | ±0.1% to ±0.5% |

| Electronic Platform Scale | Warehouse goods, pallets, small vehicles | Cantilever beam load cells under a steel platform | ±0.1% to ±0.3% |

| Electronic Balance | Laboratory samples, gold, pharmaceuticals | Electromagnetic force compensation | ±0.001% to ±0.01% |

This table makes it clear. If your client needs to weigh 40-ton trucks, only a weighbridge1 will do. If they are weighing 500 kg pallets on a factory floor, a platform scale2 is the correct choice.

What separates an industrial platform scale from a high-precision laboratory balance?

A platform scale and a lab balance both give you a weight. It's easy to think they are just different sizes of the same thing. But confusing them means using the wrong tool, leading to massive errors.

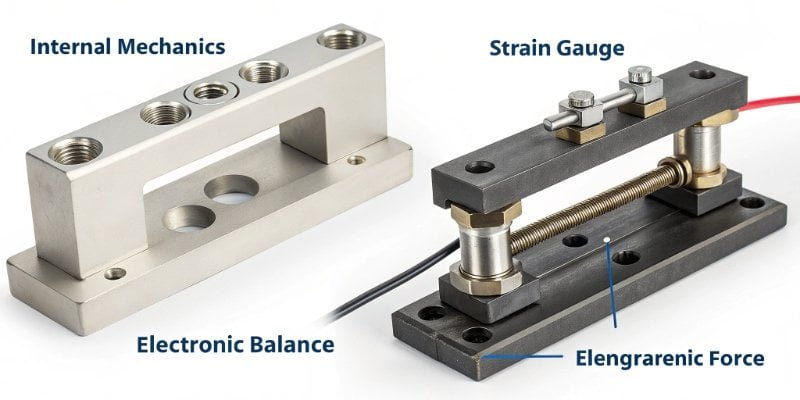

The biggest difference is their internal technology and precision. Industrial platform scales use robust strain gauge load cells for heavy loads. High-precision balances use sensitive electromagnetic force compensation for tiny, accurate measurements. Their purpose and construction are completely different.

I often explain the difference using an analogy. A platform scale is like a construction measuring tape. It's tough, reliable, and perfect for measuring large dimensions where being off by a millimeter doesn't matter. A laboratory balance3, on the other hand, is like a machinist's caliper. It's a delicate, highly precise instrument for work where a fraction of a millimeter is critical.

Let's look at the technology inside.

Industrial Platform Scales

These scales use something called a strain gauge load cell4. It’s basically a solid piece of metal (like a cantilever beam) that is designed to bend ever so slightly when a load is placed on it. This bending action stretches a sensor, changing its electrical resistance. The scale's electronics measure this change and convert it into a weight reading. This design is simple, durable, and cost-effective, making it perfect for tough factory environments where you're weighing hundreds or thousands of kilograms.

High-Precision Laboratory Balances

These use a more complex principle called electromagnetic force compensation5. Instead of measuring how much something bends, an electromagnet creates a force to perfectly counteract the weight on the pan. The scale measures the exact amount of electrical current needed to create this balancing force. Since the current is directly proportional to the mass, the scale can calculate weight with incredible precision, often down to a milligram or less. This technology is more sensitive and expensive, which is why it's reserved for labs and other clean environments.

How do capacity and readability determine the best scale for your needs?

You see "capacity" and "readability" on every spec sheet. But what do they really mean for your project? Ignoring them can lead to buying a scale that breaks or isn't precise enough for your data needs.

Capacity is the maximum weight a scale can handle, while readability is the smallest increment it can display. You need a capacity that safely exceeds your heaviest load and a readability fine enough for your required precision. Getting these two right is essential.

After helping partners select scales for nearly two decades, I've developed a simple rule of thumb to make this easy. These two specs, capacity6 and readability7, are the most critical factors in your decision after you've chosen the general type of scale.

The Importance of Capacity

Capacity is the absolute maximum weight the scale is designed to measure. A common mistake is to buy a scale with a capacity that just barely meets your needs. This is risky. As a rule, we advise that the scale's maximum capacity should be at least 1.5 times your heaviest expected load. For example, if you know the heaviest truck you will ever weigh is 20 tons, don't buy a 20-ton weighbridge. You should choose a 30-ton model. This safety margin8 protects the load cells from damage caused by shock loading (like a truck braking suddenly on the scale) and ensures a long, reliable service life.

Why Readability Matters

Readability, also known as division size, is the smallest increment the scale's display will show. This is crucial for your software. It is the finest level of detail you can capture. It's important not to confuse readability with a scale's accuracy. A scale might have readability of 1 kg, but its accuracy might be ±5 kg.

Here’s a quick guide:

| Feature | What It Is | Why It Matters for You |

|---|---|---|

| Capacity | The maximum weight the scale can measure. | Prevents overload damage, ensures safety and longevity of the hardware. |

| Readability | The smallest increment the display shows. | Determines the level of detail and granularity in the data your software can record. |

For a weighbridge, a readability of 10 kg is common. For a platform scale, it might be 0.5 kg. For a lab balance, it could be 0.001 g. You must choose a readability that matches the precision your end-user's process requires.

What are the legal-for-trade requirements for commercial weighing equipment?

Are you using a scale to determine the price of a product? This is a commercial transaction. Using a non-certified scale for this can lead to heavy fines, legal trouble, and a complete loss of customer trust.

"Legal for Trade" or "Trade Approved" scales are certified by government bodies to be accurate and reliable for commercial use. This certification is a legal requirement, not a quality suggestion, and ensures fairness when selling goods by weight.

When any transaction involves selling something by weight, the scale used for that measurement must be legally certified. This protects both the buyer and the seller. As a manufacturer selling globally, we ensure our scales meet these strict international standards.

Understanding the Certifications

Different regions have different governing bodies. In the United States, you'll look for an NTEP (National Type Evaluation Program) Certificate of Conformance. In Europe, you need a scale with a CE mark9 and a supplementary metrology marking (a green 'M'). These certifications prove that the scale's design has been tested and approved for commercial use. It confirms the scale is accurate, repeatable, and resistant to tampering. As a company that values reliability, we ensure our products carry the necessary certifications, like CE, for the markets they serve.

The Role of Calibration

Certification is just the first step. To remain compliant, the scale must be regularly calibrated by a certified technician using certified test weights. For example, a legal-for-trade truck scale typically needs to be calibrated at least every 6 months. This process verifies that the scale is still weighing accurately. For you as a software vendor, this is a huge opportunity. Your software can be designed to log calibration dates and automatically alert the user when a scale is due for service, adding significant value and ensuring your clients remain compliant. Integrating with hardware that is non-compliant is a business risk you don't want to take.

Conclusion

Choosing the right scale means matching its type, capacity, and legal status to your need. This ensures you get accurate, reliable, and compliant data for your business systems.

-

Explore this link to understand how weighbridges function and their importance in heavy load weighing. ↩

-

Learn about the advantages of platform scales for industrial applications and how they can improve efficiency. ↩

-

Discover the critical role of laboratory balances in precise measurements and their applications in various fields. ↩

-

Find out the technology behind strain gauge load cells and their significance in industrial weighing. ↩

-

Understand this advanced technology used in high-precision balances for accurate measurements. ↩

-

Explore the concept of capacity in scales and why it's crucial for selecting the right equipment. ↩

-

Learn about readability and its impact on the precision of measurements in various applications. ↩

-

Learn about the importance of having a safety margin in scale capacity to prevent overload and damage. ↩

-

Explore the meaning of the CE mark and its importance for compliance in the European market. ↩

Comments (0)