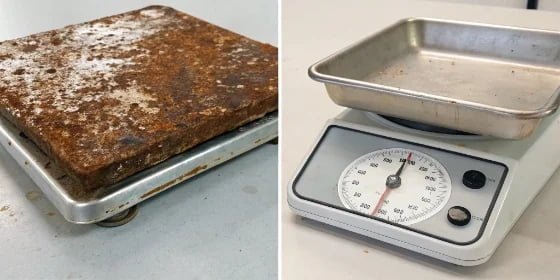

Spills and moisture ruining your expensive industrial scales? Downtime and repair costs are frustrating. A proper waterproof design prevents this and saves you money.

We design waterproof industrial scales using special materials and comprehensive sealing. The scale body and pan use waterproof, anti-corrosion materials like stainless steel. The display is fully sealed, and all connectors and cable interfaces are also waterproofed to protect the internal electronics.

This specialized design is what separates a truly industrial-grade scale1 from a standard one. It’s not just about a simple coating; it's a ground-up engineering philosophy focused on durability in the toughest environments. Over my 19 years in this industry, I’ve seen countless businesses suffer from using the wrong equipment in wet or corrosive settings. A scale that fails due to moisture isn't just an inconvenience; it can halt production entirely. That’s why understanding the details of waterproof design is so important. Let's dig deeper into what makes a scale genuinely ready for these challenges and how to choose the right one for your needs.

Are weighing scales waterproof?

Thinking all scales can handle a splash? This common mistake can lead to costly damage and inaccurate readings, especially in wet industrial environments. Let's clarify the difference.

Not all weighing scales are waterproof. Most standard scales are not designed for wet conditions. However, specialized industrial scales are often fully waterproof. These are identified by an IP (Ingress Protection) rating, like IP67 or IP68, which guarantees their ability to withstand water and dust.

The key difference lies in the terms "water-resistant" versus "waterproof." A water-resistant scale might handle a minor splash, but it won't survive being hosed down. A truly waterproof scale is built for it. This is where IP ratings come in. At Weigherps, we live by these ratings because they provide a clear, standardized measure of protection. I remember a client in the seafood processing business who learned this the hard way. His "durable" scales failed within a month. We replaced them with our IP68-rated models, and he's been using the same scales for years now without a single issue. It’s all about using the right tool for the job.

Understanding IP Ratings

An IP rating consists of two numbers. The first digit (0-6) indicates protection against solid objects (like dust), and the second digit (0-8) indicates protection against liquids (water).

| IP Rating | Protection Against Solids (First Digit) | Protection Against Liquids (Second Digit) | Typical Use Case |

|---|---|---|---|

| IP65 | 6: Dust Tight | 5: Protected against low-pressure water jets. | General factory, dusty areas. |

| IP67 | 6: Dust Tight | 7: Protected against temporary immersion in water (up to 1m). | Food processing, frequent washdowns. |

| IP68 | 6: Dust Tight | 8: Protected against long-term immersion in water. | Harshest environments, chemical plants. |

For our clients, choosing the right IP rating means balancing cost with the reality of their workplace. This ensures the scale is a long-term, reliable investment.

How do weighing scales measure water?

Trying to weigh liquids accurately is tricky. Spills, evaporation, and the weight of the container itself can create a mess and lead to frustrating errors. So how do scales handle this?

Scales measure the mass of water, not "water" itself. For bulk liquid, you use the tare function to zero out the container's weight. For hydration analysis in smart scales, they use Bioelectrical Impedance Analysis (BIA) to estimate the body's water percentage by measuring electrical resistance.

This question has two very different answers depending on the context. As a manufacturer, I deal with both, but they involve completely different technologies. On the industrial side, precision is about process. You place an empty container on the scale, press the 'TARE' button to reset the display to zero, and then add your liquid. The scale then shows only the weight of the liquid. For unstable liquids, we even have a "dynamic weighing" mode that averages the weight over a few seconds to get a stable reading.

The other side is hydration measurement, which is more common in consumer or medical-tech products. This doesn't use a load cell to weigh water. It uses Bioelectrical Impedance Analysis (BIA)2. The scale sends a tiny, safe electrical current through your body. Since water conducts electricity well and fat does not, the scale measures the resistance (impedance). Software inside the scale then uses this data, plus your personal stats like age and height, to estimate your body water percentage. It's a fascinating piece of technology that shows how "weighing" is evolving.

What are the different types of industrial weighing scales?

Overwhelmed by the sheer number of industrial scales available? Choosing the wrong one can hurt your work efficiency and your budget. Let's simplify the main types to find your perfect match.

Industrial weighing scales are categorized by their use. Common types include bench scales for small items, floor scales for pallets, counting scales for inventory, and truck scales for vehicles. Each type is designed for a specific capacity, environment, and task.

In my experience, the biggest mistake customers make is buying a scale based only on price or maximum capacity. The application is what truly matters. We spend a lot of time at Weigherps helping our clients diagnose their actual needs. For instance, a software company that needs to kit small hardware components with its product doesn't need a massive floor scale; they need a high-precision counting scale. This type of scale can determine the quantity of thousands of tiny screws by weighing a small sample and then the total batch. It saves a massive amount of time and eliminates human error. Conversely, a logistics company needs a robust floor scale or pallet jack scale to quickly weigh incoming and outgoing shipments. The right scale streamlines your workflow.

Common Industrial Scale Types

Understanding the basic categories helps narrow down the choices. Here’s a simple breakdown of the scales we manufacture and customize.

| Scale Type | Typical Use Case | Common Capacity Range | Key Feature |

|---|---|---|---|

| Bench Scale | Workshops, labs, shipping desks | 1 kg - 150 kg | Compact and versatile |

| Counting Scale | Inventory, parts packaging | 1 kg - 30 kg | High precision for identical items |

| Floor Scale | Warehouses, receiving docks | 500 kg - 10,000 kg | Large platform for pallets, crates |

| Truck Scale | Logistics hubs, raw material sites | 20,000 kg - 100,000 kg+ | Weighs entire vehicles |

| Crane Scale | Manufacturing, foundries, shipping | 100 kg - 50,000 kg | Suspended for overhead weighing |

Choosing the correct scale isn't just about weight; it is about making your entire process more efficient and profitable.

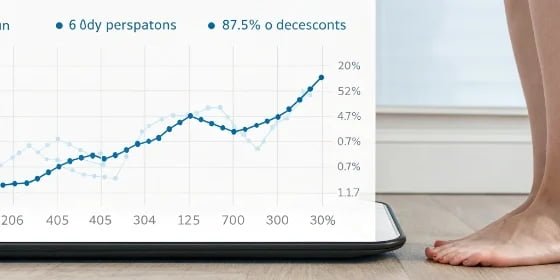

How accurate are scales that measure hydration?

You're relying on your smart scale's hydration number, but the readings can fluctuate wildly. This might make you doubt their usefulness entirely. Let's look at what affects their accuracy.

Scales measuring hydration with BIA provide a good estimate for trends but are not medically precise. Their accuracy is easily affected by your body's current state, including recent exercise, meals, and your actual hydration level. They are best used for tracking changes over time.

As someone in the measurement business, I find BIA technology fascinating but also recognize its limitations. These scales are not laboratory instruments. Their primary value is in showing you a trend, not a single, perfectly accurate number. For a software vendor developing apps for smart devices, managing user expectations is critical. The readings can be influenced by many factors. For example, if you weigh yourself right after a tough workout, you've lost water through sweat, and your reading will reflect that. If you weigh yourself after drinking a liter of water, your reading will change again.

Factors That Influence BIA Accuracy

- Time of day: Weigh yourself at the same time each day, preferably in the morning, for consistency.

- Hydration level: Ironically, being very dehydrated or over-hydrated can skew the electrical impedance measurement.

- Recent meals and drinks: Food and fluid in your system will affect the reading.

- Exercise: Wait several hours after exercise to measure.

- Foot condition: Clean, dry feet are essential. Calluses can interfere with the electrical contacts.

The key is consistency. By controlling these variables, a user can get a reliable trend line of their body water percentage. It’s an excellent tool for personal wellness tracking, as long as everyone understands it's an estimate, not a diagnosis.

Conclusion

From rugged waterproof designs to smart hydration analysis, the right scale technology empowers your business. We build reliable solutions to help you achieve new levels of efficiency and growth.

Comments (0)