Are you puzzled by how a simple platform can instantly tell you a precise weight? This lack of clarity can make choosing a reliable scale for your business feel uncertain.

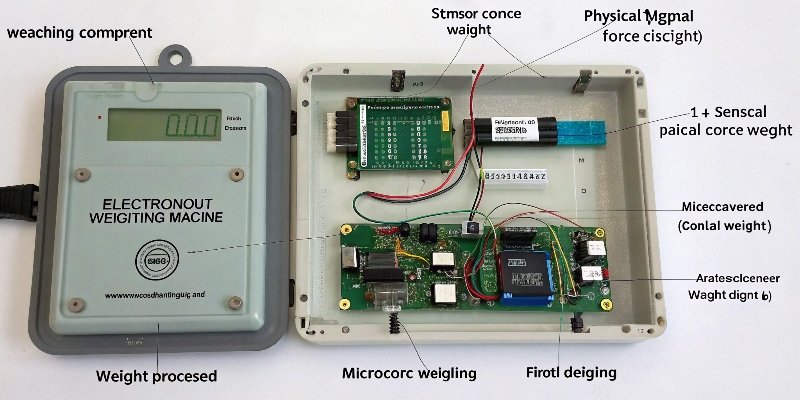

An electronic weighing machine works by using sensors to convert the physical force of weight into a small electrical signal. This signal is then amplified, converted into digital data, processed by a microprocessor for accuracy, and finally shown as a weight reading on a display.

Understanding this basic process is just the first step. To truly appreciate the technology and make the best choice for your industrial needs, we need to examine each part of the process more closely. This knowledge will empower you to select a scale that is not just accurate, but perfectly suited for your operations. Let's dig deeper into the core principles that make modern weighing possible.

What is the principle of an electronic weighing machine?

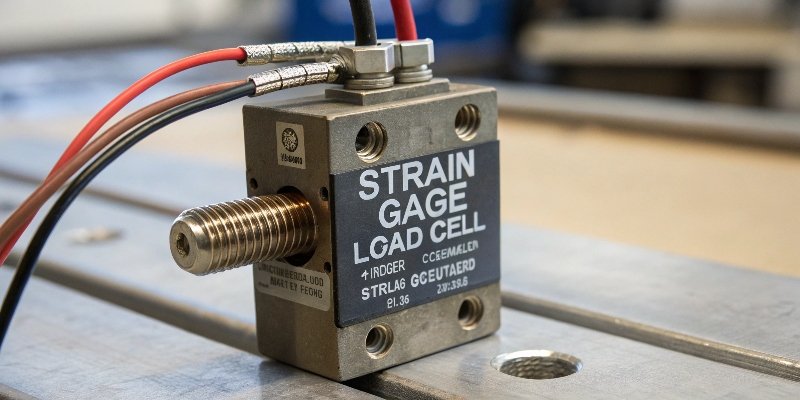

You often hear terms like "load cell" and "strain gauge," but they can sound like complex technical jargon. Ignoring these principles means you might buy a scale that isn't right for your industrial environment, leading to costly errors. Grasping the basic idea is actually quite simple.

The main principle is converting mechanical force into a measurable electrical signal. Most scales do this with a strain gauge bonded to a load cell. When weight is applied, the load cell bends slightly, changing the electrical resistance of the strain gauge. This change is proportional to the weight.

How a Sensor Creates a Signal

At the heart of most electronic scales is a component called a load cell1. A load cell is a carefully engineered piece of metal, often aluminum or steel, that is designed to deform in a predictable way when a force is applied. Bonded to this metal block is a tiny sensor called a strain gauge2. The strain gauge is essentially a flexible foil with a metallic resistor pattern on it. When you place an object on the scale, the load cell bends ever so slightly. This stretches or compresses the strain gauge, which in turn changes its electrical resistance. The change is incredibly small but directly related to the amount of force, or weight, being applied. This is the fundamental conversion of physical force into an electrical property.

Turning a Tiny Change into a Usable Signal

A single strain gauge's resistance change is too small to measure reliably on its own. That's why scales typically use four strain gauges arranged in a configuration called a Wheatstone bridge3. This circuit is excellent at detecting minuscule changes in resistance. As weight is applied and the resistances of the four gauges change, the bridge becomes unbalanced. This imbalance creates a tiny, measurable voltage difference across the circuit. This voltage is the raw analog signal that represents the weight on the scale. Different sensor types4 exist, but the strain gauge load cell offers the best balance of cost, reliability, and accuracy for most industrial and commercial applications.

| Sensor Type | Operating Principle | Common Application |

|---|---|---|

| Strain Gauge | Resistance changes with physical deformation. | Industrial scales, retail scales, lab balances |

| Capacitive | Capacitance changes as plates move closer/further. | High-precision devices, touch screens |

| Piezoelectric | Generates a voltage when pressure is applied. | Dynamic force measurement, pressure sensors |

How does the scale process the sensor's signal?

A raw electrical signal from a sensor is weak, noisy, and not directly useful. Without proper processing, your scale would give fluctuating, inaccurate readings, making it worthless for any professional task. Luckily, a multi-step process turns this raw data into a stable number.

The scale first amplifies the weak analog signal and filters out interference. An Analog-to-Digital Converter (ADC) then transforms it into digital data. Finally, a microprocessor uses this data, applying calibration factors, to compute the final, accurate weight displayed on the screen.

From Weak Signal to Strong Data

The voltage signal from the Wheatstone bridge is extremely small, often in the microvolt range. It's also susceptible to picking up electrical "noise" from the surrounding environment. The first job of the scale's internal electronics is to feed this signal into an instrumentation amplifier. This amplifier boosts the signal to a level that can be processed effectively while simultaneously filtering out unwanted noise. At our manufacturing facility, I've seen firsthand how crucial a well-designed filtering circuit is. A poorly filtered signal results in a bouncing number on the display, which is unacceptable for our clients who rely on stable readings. This clean, amplified signal is still analog, like a continuous wave, and needs to be converted for the next step.

Converting from Analog to Digital

The "brain" of the scale, the microprocessor5, can only understand digital information—ones and zeros. Therefore, the clean analog signal must be converted. This is the job of the Analog-to-Digital Converter, or ADC. A popular and highly reliable chip used for this in many weighing applications is the HX711. The ADC measures the analog voltage thousands of times per second and converts each measurement into a digital value. The higher the resolution of the ADC (e.g., 24-bit), the smaller the weight increments it can detect, leading to a more precise scale. This stream of digital data is now ready to be interpreted by the microprocessor.

What is the difference between digital and electronic weighing scales?

The terms "digital" and "electronic" are used so often with scales that you might wonder if they mean the same thing. This small confusion can make it harder to compare products and know what technology you are actually getting. Knowing the simple difference clarifies exactly what you are buying.

Essentially, all modern digital scales are electronic, but the term "electronic" is broader. An "electronic" scale is any scale using electronics. A "digital" scale is a specific type of electronic scale that processes the signal digitally and shows the result as numbers on a screen.

In today’s market, the two terms have become almost interchangeable, but there is a technical distinction rooted in their history. The term "electronic scale" can refer to any weighing device that uses electronic components to function. Very early electronic scales might have used analog circuits to drive a physical needle on a dial. The process was electronic, but the output was analog.

A "digital scale," on the other hand, specifically refers to the modern standard. These scales not only use electronic components like strain gauges but also incorporate the crucial digital processing steps we've discussed: an Analog-to-Digital Converter (ADC)6 and a microprocessor. This is what makes a scale "smart." The microprocessor doesn't just display a number; it runs software that can perform tare functions, switch units, and apply complex calibrations. Because virtually every electronic scale manufactured today uses a digital processor and display, the terms are now used as synonyms. When you buy an electronic scale from a manufacturer like Weigherps, you are getting a fully digital device.

| Feature | Early "Electronic" Scale (largely obsolete) | Modern "Digital" Scale |

|---|---|---|

| Signal Processing | Analog circuits | ADC and Microprocessor |

| Display | Analog dial or needle | Digital (LCD/OLED) numeric display |

| Functionality | Basic weight measurement | Advanced (tare, unit switching, counting) |

| Modern Usage | Obsolete | The current standard for all scales |

How do scales ensure accuracy and connectivity?

An inaccurate or disconnected scale is a huge liability in any modern business. You risk production mistakes, compliance issues, and wasted hours manually entering data, all of which damage your efficiency and profitability. Modern scales solve this with precise calibration and smart connectivity features.

Accuracy is maintained through regular calibration using certified weights and smart software that compensates for environmental factors. Connectivity is achieved with built-in modules like Bluetooth or Wi-Fi, allowing scales to send data to apps, cloud systems, and integrate with your existing IoT infrastructure.

Guaranteeing Accuracy

A scale's accuracy is not permanent. Over time, factors like temperature changes, mechanical stress, and component aging can cause measurement drift. This is why calibration is essential. Calibration is the process of adjusting the scale's software to match a known, certified weight. For example, you place a 10kg certified weight on the scale and tell the microprocessor, "This signal equals 10kg." The processor then stores this data and uses it as a reference for all future measurements. For rugged industrial environments, we also build our scales with robust designs that resist vibrations and electromagnetic interference (EMI) to protect the sensitive internal electronics and maintain accuracy even in challenging conditions.

Smart Data for a Smart Factory

A scale that just shows a number is no longer enough. As a software provider, you know that data is king. That's why our industrial scales7 are designed for connectivity. With options like Bluetooth and Wi-Fi, the weight data can be instantly transmitted to a host device. This opens up endless possibilities for your clients. Imagine a warehouse where package weights are automatically sent to the shipping software, or a factory where ingredient measurements are logged in a quality control system in real-time. This is the power of the Industrial Internet of Things (IIoT), and it starts with a reliable, connected weighing solution. We provide the hardware and support to help you integrate our scales seamlessly into the smart systems you build.

Conclusion

In short, electronic scales smartly convert weight into digital data using sensors and processors. Understanding this simple process helps you choose the right, reliable, and connected scale to advance your business.

- Learn about load cells, their importance in scales, and how they ensure accurate weight measurements. ↩

- Discover the role of strain gauges in load cells and their significance in weight measurement technology. ↩

- This resource explains the Wheatstone bridge configuration and its application in precise weight measurement. ↩

- Learn about various sensor types and their applications in different weighing scenarios. ↩

- Explore how microprocessors enhance the functionality and accuracy of modern electronic weighing scales. ↩

- Understand the function of ADCs in converting analog signals to digital data for accurate weight readings. ↩

- Explore the features and benefits of industrial scales in various business environments. ↩

[…] sensor is an analog signal. It’s too small to be useful on its own. So, a chip (like the popular HX7113) amplifies this signal. Then, an analog-to-digital converter (ADC) turns it into a digital number […]