Are you worried about overloading fines and safety risks? Inaccurate freight weights can lead to costly penalties and dangerous road conditions, hurting your business and reputation.

Floor scales and axle scales optimize transportation by providing the accurate weight of a vehicle. This data is essential to prevent overloading, avoid expensive fines, improve road safety with balanced loads, and increase overall supply chain efficiency.

You know that weighing your trucks is important. But choosing between a floor scale and an axle scale can be confusing. Making the right choice is key to a smart investment that fits your specific needs. Let's look closer at the details to help you decide which scale is best for your operation.

What are the key differences between floor scales and axle scales for shipping?

Choosing the wrong scale for your business can be a big problem. You might spend too much money, or you might get weights that are not accurate. Let's fix this.

The main difference is in their design and best use case. Floor scales are permanent, offer the highest accuracy by weighing the whole truck at once, and are ideal for fixed locations. Axle scales are portable, cheaper, and weigh one axle at a time, making them better for mobile check-weighing.

Let's dive deeper into what sets these two types of scales apart. Understanding their specific strengths will help you make a much better decision for your logistics.

Floor Scales (Weighbridges)

Floor scales, which are also called weighbridges or truck scales, are built into the ground. They need a concrete foundation, so the initial cost is higher. But they give you the most accurate weight because they measure the entire vehicle in one go. This makes them perfect for places that don't move, like our clients' factories, recycling centers, and large shipping depots. I remember a client who was struggling with weight disputes from their carriers. After we installed a permanent floor scale at their main warehouse, their records became perfectly accurate. It completely solved their problem and saved them a lot of money in the long run.

Axle Scales

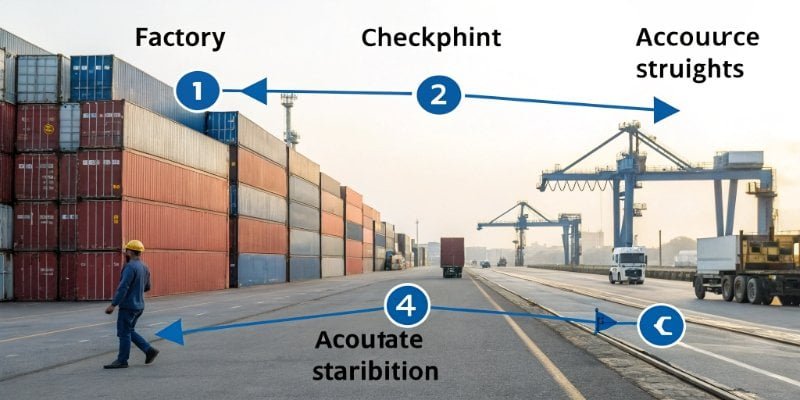

Axle scales are the flexible option. They are portable, so you can move them wherever you need them. You just place them on a flat surface and drive the truck over them, one axle at a time. The scale then adds up the weights of all the axles to get the total vehicle weight. Because the weight can shift slightly as each axle is weighed, they are a little less accurate than a full-sized floor scale. But they are much less expensive and are great for temporary job sites or for businesses that need to check weights at multiple loading docks.

| Feature | Floor Scale (Weighbridge) | Axle Scale |

|---|---|---|

| Installation | Permanent, needs foundation | Portable, minimal setup |

| Accuracy | Very High | Good, but slightly less precise |

| Cost | High initial investment | Lower initial cost |

| Best Use Case | Fixed locations, high volume | Mobile weighing, roadside checks |

| Weighing Method | Entire truck at once | One axle at a time |

How can using vehicle scales help prevent costly truck overloading fines?

Overloading fines are a huge, unexpected cost for many businesses. A single fine can wipe out the entire profit from a shipment. Don't let a simple weighing mistake hurt your company.

Vehicle scales give you the exact weight of your truck before it leaves your facility. This ensures you are following legal weight limits. By catching and correcting an overload early, you completely avoid large fines, mandatory unloading, and other serious penalties.

The rules for vehicle weight are very strict, and for good reason. Overloaded trucks are a danger on the road. Let's look at how a scale becomes your best protection against these fines.

Most countries and states have very specific laws about how much a truck can weigh. There are limits for the total weight, called the Gross Vehicle Weight (GVW)1, and for the weight on each axle. If you get caught over these limits, the consequences are expensive. Fines can be thousands of dollars. Sometimes, authorities will force your driver to unload the extra cargo right there on the side of the road, causing major delays. In serious cases, they can even impound the vehicle. A wholesaler we started working with learned this the hard way. They were hit with a $5,000 fine for one overloaded truck. After that, they bought several of our portable axle scales2 to use at their loading docks. They told me they haven't had a single fine since. A scale is truly an investment that pays for itself very quickly. It protects you from fines and keeps your trucks moving.

What are the best practices for balancing freight loads to improve road safety?

An unbalanced truck is a serious danger. It can tip over on a turn or lose control during a sudden stop. This puts your driver, your cargo, and everyone else on the road at risk.

The best practice is to distribute weight evenly across the truck. Use axle scales to check the weight on each axle as you load. Place heavy items low and in the center. Then, secure the entire load so it cannot shift during the trip.

Balancing a load is about more than just staying under the weight limit. It's about physics and control. An unbalanced load creates a high center of gravity, which makes the truck unstable. It also causes uneven wear on tires and brakes, and it makes the truck much harder to handle, especially in bad weather or an emergency. As a scale manufacturer, we see this as part of our responsibility. Our products help companies follow the law, but we also want to promote practices that protect lives. An overloaded or unbalanced truck is a threat to the public.

Here are some simple steps to follow:

- Know the Limits: Before you start loading, know the truck's Gross Vehicle Weight and individual axle weight limits.

- Load Heavy First: Place the heaviest items on the floor and between the axles.

- Spread the Weight: Distribute the load evenly from side to side and front to back.

- Check as You Load: Use axle scales to check weights during the loading process, not just at the end. This lets you make adjustments easily.

- Secure Everything: Use straps, braces, and blocks to keep the cargo from moving.

Why is accurate weight management crucial for overall supply chain efficiency?

Are you just guessing weights in your supply chain? This can lead to shipping errors, problems with customers, and wasted fuel. These small issues can add up to very big losses over time.

Accurate weight management is crucial because it provides reliable data that improves every step of the supply chain. It helps optimize shipping costs, improves inventory control, prevents fines, and ensures fair billing. This makes the entire process from factory to customer more efficient.

Think of accurate weight as the foundation of good logistics. When you have reliable weight data, you can make smarter decisions everywhere. It affects more than just one truck or one shipment; it impacts your entire operation. For example, shipping carriers charge based on weight. If your weights are accurate, you pay the correct amount and can choose the most cost-effective service. In your warehouse, accurate weights help you manage inventory better. You know exactly how much product you have on hand. When it comes to planning, you can load trucks to their maximum legal capacity without going over, which means fewer trips and lower fuel costs. For many of our clients in industries like agriculture or scrap metal, they buy and sell goods based on weight. For them, accuracy is essential for fair and transparent business.

| Area of Supply Chain | Impact of Inaccurate Weight | Impact of Accurate Weight |

|---|---|---|

| Shipping Costs | Overpaying for shipping | Paying the correct, optimized price |

| Legal Compliance | Fines, delays, legal issues | Smooth transit, no penalties |

| Customer Relations | Disputes over quantities | Trust and transparency |

| Operational Planning | Inefficient truck loading | Maximum payload, fewer trips |

Conclusion

Using floor and axle scales correctly prevents fines, improves safety, and boosts supply chain efficiency. Accurate weighing is the foundation of smart, profitable, and responsible transportation.

[…] for overload fines3, vehicle […]