Unstable scale readings are wrecking your production line. You suspect the load cell is the issue but aren't sure. Here's how to confirm the problem without guessing.

Check for erratic weight data, like drifting numbers or errors when using standard weights. A visual inspection for physical damage and a quick resistance test with a multimeter can also quickly tell you if the load cell is the culprit.

These initial signs are strong indicators of a problem. But you need a systematic way to be certain you are replacing the right part. As an industrial scale manufacturer for over 18 years, I've seen it all. I can walk you through the exact steps to diagnose the problem correctly and get your operations back on track. Guesswork costs time and money, so let's get you a clear answer.

How to test if a load cell is bad?

Getting inaccurate measurements from your scale? It’s frustrating and can be costly. You need a reliable test to know if your load cell is failing before it causes bigger problems.

Use a multimeter to measure the input and output resistance. Compare this reading to your manufacturer's specifications. If the deviation is greater than ±5%, the load cell is likely bad. Also, check for consistent, correct readings under a standard weight.

To properly test a load cell, we break it down into a few clear steps. Some are quick checks you can do yourself, while others might require a bit more expertise.

Quick Electrical Check

This is often the fastest way to confirm a fatal flaw. You will need a multimeter1. Disconnect the load cell from the indicator and set your multimeter to the Ohms setting. Measure the resistance between the input wires (usually red and black) and then between the output wires (usually green and white). Your load cell's data sheet will tell you the correct resistance values. If your measured values are more than 5% off from the specs, the internal strain gauge2 is likely damaged. It is a strong sign that you need a replacement.

Calibration Sensitivity Test

If the electrical test passes, check the load cell's performance. With no weight on the scale, make sure it reads zero. Then, place a known standard weight on it, like a 10kg calibration weight3. The reading should be exactly 10kg within the allowed tolerance (e.g., ±0.05kg). If the value is off or it slowly drifts up or down, the load cell is no longer stable or accurate.

Advanced Diagnostic Tests

For a definitive diagnosis, a professional technician performs more in-depth tests. These confirm subtle issues that a basic check might miss.

| Test | Method | Failure Indication |

|---|---|---|

| Linearity | Add weights in stages and record the readings. | The measured curve deviates from a straight line by >3%. |

| Insulation Resistance | Use a megohmmeter to measure insulation resistance4. | The value is less than 2000MΩ. |

| Temperature Drift | Monitor readings as the ambient temperature changes. | The error is >±0.03kg for every 10°C change. |

These tests give a complete picture of the load cell's health, ensuring you only replace what's truly broken.

How to fault find a load cell?

Your scale is acting up, but many parts could be the cause. Guessing which component to replace costs time and money. Here is a clear process to isolate the fault to the load cell.

Start with the simple things. Check the scale's display for error codes and inspect all cable connections between the load cell and the indicator. A simple visual check of the load cell for physical damage can often pinpoint the problem.

Fault finding is a process of elimination. As a manufacturer, we guide our clients through this methodically to save them from unnecessary expenses. Follow these steps to narrow down the issue.

Start with the Symptoms

The first clue is always how the scale is misbehaving. Different symptoms point to different potential problems.

For example, if the reading on the display is fluctuating wildly even with nothing on the scale, it often points to a damaged load cell or a bad cable connection.

| Symptom Displayed | Possible Load Cell Issue |

|---|---|

| Weight drifts and won't stabilize | Internal component failure or temperature sensitivity. |

| Inaccurate reading with a known weight (e.g. ±0.1kg error) | Loss of calibration, potential strain gauge damage. |

| No reading or "OL" (Overload) on the display | Complete circuit failure, severed cable, or major damage. |

| Unstable reading when empty (e.g. ±0.5kg) | Moisture ingress or electrical interference. |

Conduct a Physical Inspection

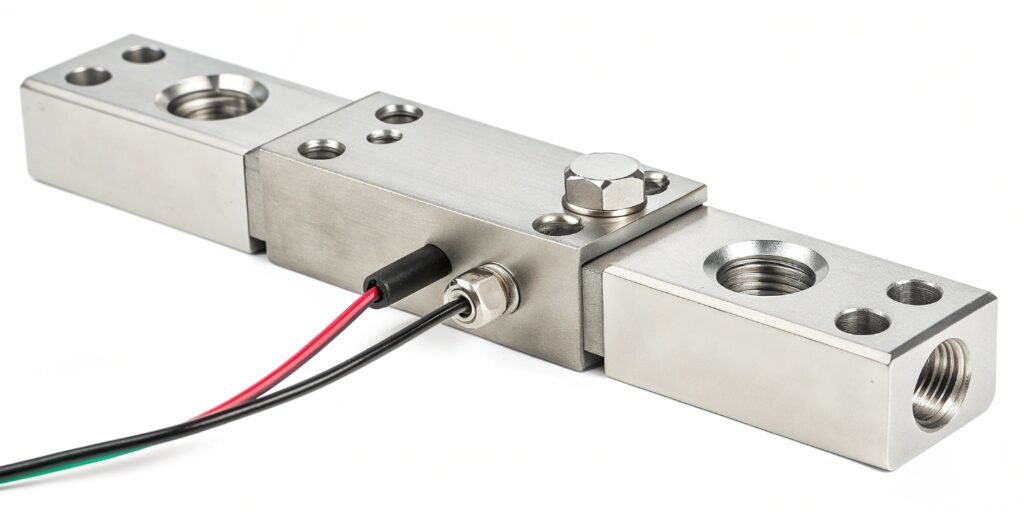

Next, look closely at the load cell and its surroundings. Is the surface clean? Dust, grease, or other debris can interfere with performance. Look for signs of physical damage like deep scratches, dents, or corrosion. These are clear indicators of impact or environmental damage. Also, gently tap the load cell's housing. If you hear a rattling sound, it means something is loose inside, and the cell is definitely compromised.

Verify Connections and System Errors

A load cell failure isn't always about the cell itself. Trace the cable from the load cell back to the junction box or indicator. Look for cuts, abrasions, or tight bends that could damage the internal wires. Check that all connections are tight and free of corrosion. Sometimes, the scale’s indicator will give you a clue. An error code like “ERR-03” might point to a connection fault, not a broken load cell. Always consult your manual to understand what these codes mean.

What causes load cell failure?

You just replaced a load cell, and now another one has failed. It's a frustrating and expensive cycle. Understanding the root cause is key to preventing future failures and saving money.

The most common causes are overloading, shock loading from a dropped object, and environmental damage from moisture or corrosion. Electrical issues like power surges or lightning can also instantly destroy a load cell.

Over the years, we've helped countless clients troubleshoot repeat failures. It almost always comes down to one of these three categories. By addressing the root cause, you can significantly extend the life of your weighing equipment.

Mechanical Stress

This is the number one killer of load cells.

- Overloading: Every load cell has a maximum capacity. Exceeding this limit, even for a moment, can permanently damage the internal strain gauges.

- Shock Loading: This happens when a heavy weight is dropped onto the scale instead of being placed gently. The sudden force is many times greater than the static weight, causing immediate failure.

- Fatigue: Even if you stay within the weight limit, millions of repetitive loading cycles over many years can eventually cause the metal components to fatigue and fail.

Environmental Exposure

Load cells often work in tough conditions. If they are not properly specified for the environment, they will fail prematurely.

- Moisture and Water: Water getting inside the load cell is a common problem. It causes short circuits and corrosion. A high IP rating5 (like IP67 or IP68) is essential for wet environments.

- Corrosive Chemicals: In chemical plants or food processing facilities with harsh wash-down procedures, acids and other chemicals can eat away at the load cell's body and seals. Stainless steel load cells are a must in these cases.

- Temperature: Extreme heat or cold, or rapid temperature changes, can cause the readings to drift or damage sensitive components.

Electrical Problems

Sometimes, the problem comes from the power supply, not the physical load.

- Power Surges: A sudden spike in voltage from the power grid or nearby heavy machinery starting up can fry the delicate electronics inside a load cell.

- Lightning: A nearby lightning strike can induce enough current into the wiring to destroy a whole system of load cells instantly. Proper grounding and surge protection are critical in lightning-prone areas.

- Improper Wiring: Bad grounding or faulty wiring can create electrical noise that leads to unstable readings and can eventually damage the load cell.

Can a load cell be repaired?

A faulty load cell is disrupting your operations. You might wonder if a repair is cheaper than a replacement. But a bad repair could lead to even more downtime and inaccuracy.

Generally, repairing a load cell is not recommended or cost-effective. They are precision, factory-sealed instruments. Any attempt to repair them often compromises their accuracy and seal, leading to future failures. Replacement is the safest, most reliable option.

In our business, we are often asked about repairs. While it seems like a way to save money, my experience shows it's usually the opposite. Here’s why we almost always recommend replacement.

The Challenge of Precision

A load cell isn't just a simple piece of metal. Inside its sealed body is a highly sensitive strain gauge bonded with micro-level precision. The entire unit is hermetically sealed at the factory to protect it from dust and moisture. Once you open it, that controlled environment is gone. It's nearly impossible to re-seal it to the original factory standard in the field. Any contamination or moisture that gets in will cause it to fail again quickly. The repair itself is also extremely difficult and requires specialized equipment.

Cost vs. Reliability

Let’s talk about the cost. The labor for a specialized technician to even attempt a repair is high. After the repair, the load cell must be completely recalibrated, which takes more time and equipment. When you add up these costs, you often find they are close to, or even more than, the price of a brand-new load cell. And even after all that, the repair comes with no guarantee. A new load cell, on the other hand, comes with a warranty and the assurance of factory-tested accuracy and reliability.

When to Replace, Not Repair

Think of an industrial-grade load cell like a critical component in your car, such as a sensor. It has a typical lifespan of 5 to 8 years under normal use. When it fails, you replace it. The only small exception for repair might be a damaged cable near the exit point, which a skilled technician can sometimes fix. However, if the fault is internal to the load cell body, replacement is the only logical choice. It is faster, more reliable, and ultimately more cost-effective because it minimizes downtime and protects your production quality.

Conclusion

Identifying a bad load cell is simple with these tests. Understanding failure causes helps with prevention. For reliable accuracy, always choose replacement over risky, uncertain repairs.

-

Learn the proper techniques for using a multimeter to diagnose load cell issues effectively. ↩

-

Discover the role of strain gauges in load cells and their importance in measurement. ↩

-

Find out how calibration weights ensure accurate load cell performance and testing. ↩

-

Learn about the methods to measure insulation resistance and its importance. ↩

-

Learn about IP ratings and their significance in protecting load cells from environmental factors. ↩

Comments (0)