Struggling to understand the core of modern weighing technology? This knowledge gap can complicate system integration and purchasing decisions. We'll demystify how load cells convert physical force into usable data.

A load cell works by converting mechanical force into a measurable electrical signal. An elastic body deforms under weight, and this tiny change is detected by a sensor, typically a strain gauge, which alters its electrical resistance in direct proportion to the applied force.

Understanding this basic function is the first step. But as a purchasing manager or technical director, you know the details are what matter for successful integration. The real magic happens in the components and the principles that govern them. This knowledge is crucial for choosing a sensor that guarantees the stability and accuracy your software systems rely on. Let's dig deeper into the mechanics of how this essential conversion happens.

What is the basic principle behind load cell operation?

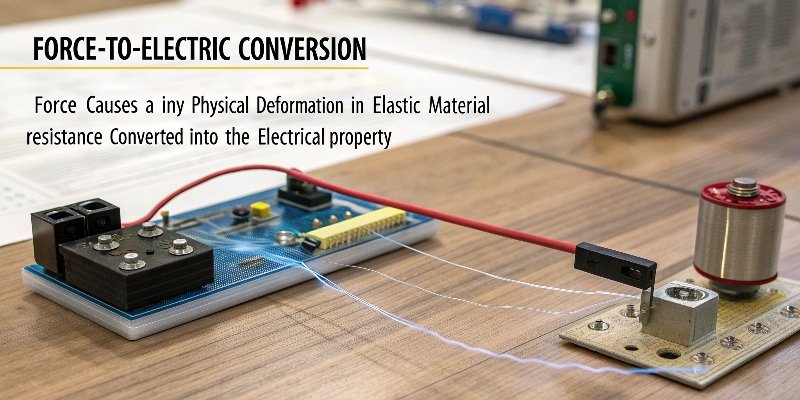

The term "force-to-electric conversion" sounds complex and technical. Without understanding this principle, choosing the right sensor for your project feels like guesswork, a risk you can't afford. Let's break down this fundamental concept.

The basic principle is force-to-electric conversion. When a force is applied, it causes a predictable, tiny physical deformation in an elastic material. This deformation is then measured and converted into a change in an electrical property, like resistance, that directly corresponds to the force's magnitude.

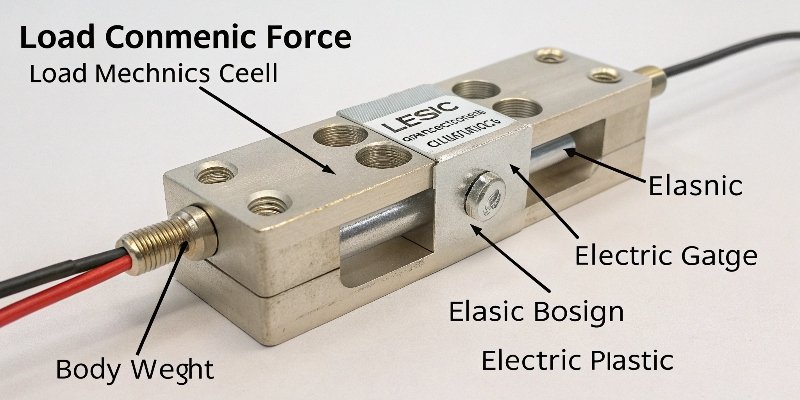

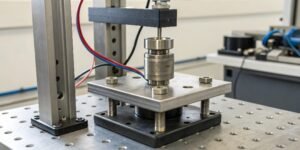

In my 18 years of designing weighing systems, I've found it helpful to think of it in three simple stages. First, a force must be applied. Second, something has to react to that force. Third, that reaction must be measured. In a load cell1, this process is highly engineered for precision. The core components making this happen are the elastic body2 and the sensing element3.

The Key Components

- Elastic Body: This is the load cell's structure, often made from high-strength alloy steel or aluminum. It is meticulously designed to deform in a consistent and repeatable way under load, then spring back to its original shape once the load is removed. Its shape (e.g., beam, S-type) determines how it handles force.

- Sensing Element: This is what "reads" the deformation of the elastic body. The most common sensing element is a strain gauge4, but others like piezoelectric materials are also used.

The entire system is designed so that the change in the sensing element is directly proportional to the force applied, ensuring an accurate and reliable measurement.

How do different types of load cells (e.g., strain gauge, hydraulic, pneumatic) function?

You know that not all load cells are created equal. Choosing the wrong type for your application can lead to inaccurate data, system failure, or unnecessary costs. Let's explore the main types and their functions.

Strain gauge types use electrical resistance changes, hydraulic types use fluid pressure changes based on Pascal's law, and pneumatic types use air pressure to balance the load. Each is suited for different applications, from static weighing to hazardous environments.

The right choice depends entirely on your specific needs, such as the environment, the type of force being measured (static or dynamic), and the required level of precision. At Weigherps, we help clients navigate these options daily to find the most cost-effective solution5. Here is a breakdown of how each one works.

| Load Cell Type | Operating Principle | Common Application | Key Advantage |

|---|---|---|---|

| Strain Gauge | Piezoresistive effect: Material's resistance changes with mechanical strain. | Industrial scales, process control | High accuracy, versatility, cost-effective |

| Hydraulic | Pascal's Law: Force applied to a confined fluid increases pressure throughout the fluid. | Tank and hopper weighing, explosive areas | Extremely rugged, immune to electrical interference |

| Pneumatic | Force Balance: Air pressure is adjusted to balance the load and maintain a fixed position. | Food processing, hazardous environments | High accuracy, safe, cleans easily |

Strain gauge load cells are the most common in modern industry due to their excellent balance of performance and cost. Hydraulic systems are unmatched for heavy-duty, rugged applications where electricity is a hazard. Pneumatic load cells offer high sensitivity and safety, making them ideal for specific clean-room or hazardous material applications.

What role do strain gauges play in the measurement process of a load cell?

You've heard that strain gauges are important, but why exactly? Overlooking their precise role is like building a complex software system without understanding the underlying operating system. We'll pinpoint their crucial function.

A strain gauge is the primary sensing element in most modern load cells. It's essentially a tiny resistor that deforms along with the load cell's body. This physical change alters its electrical resistance, providing the raw data that becomes a precise weight measurement.

A strain gauge works because of something called the piezoresistive effect6. In simple terms, when the metallic foil of the gauge is stretched, it gets longer and thinner, increasing its electrical resistance. When it's compressed, it gets shorter and wider, decreasing its resistance. This change, though incredibly small, is the foundation of the measurement.

The Wheatstone Bridge Advantage

A single strain gauge is rarely used alone because the change in resistance is tiny and susceptible to temperature fluctuations. Instead, we use four strain gauges arranged in a Wheatstone Bridge7 circuit. Two gauges are placed to measure tension (stretching), and two are placed to measure compression. This clever configuration accomplishes two things:

- Amplifies the Signal: It magnifies the small changes in resistance into a more usable output voltage.

- Compensates for Temperature: As temperature changes, all four gauges change resistance equally, keeping the bridge balanced and canceling out any temperature-induced errors. This ensures the output signal is only due to the applied force, guaranteeing measurement stability.

How does a load cell convert force or weight into an electrical signal?

The final step in the process, from physical deformation to a digital signal your software can use, might seem like a black box. Without this clarity, troubleshooting or integrating new weighing systems is much harder. Let's trace the signal path step-by-step.

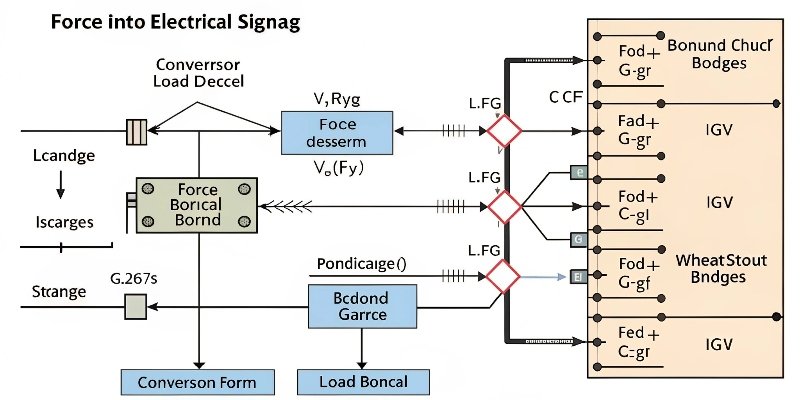

A load cell converts force to a signal through a sequence: force deforms the cell's body, and bonded strain gauges change resistance. Arranged in a Wheatstone bridge, this unbalances the circuit, producing a small output voltage (mV) directly proportional to the force.

We've covered the parts, but let's put it all together into a clear workflow. From my experience helping software providers integrate our hardware, understanding this full sequence is key to a smooth and successful project. It removes the mystery and allows your technical team to interface with the hardware confidently.

The Full Conversion Workflow

- Force Application: A weight or force is applied to the scale, which is mechanically linked to the load cell.

- Elastic Deformation: The load cell’s metal body (the elastic element) deforms slightly. This deformation is microscopic but highly predictable.

- Resistance Change: The strain gauges bonded to the structure stretch or compress along with it. This causes a proportional change in their electrical resistance.

- Voltage Signal Generation: The Wheatstone bridge circuit, which is powered by a stable excitation voltage, becomes unbalanced due to the resistance changes. This produces a very small, low-level analog signal, usually measured in millivolts per volt (mV/V).

- Signal Processing: This weak analog signal is sent to a weighing indicator8 or transmitter. There, it is amplified and converted into a digital signal using an Analog-to-Digital Converter (ADC). This clean, digital output can then be displayed as a weight or sent to a computer, PLC, or your software for processing.

Conclusion

Load cells expertly convert physical force into usable electrical data. Understanding this principle is crucial for selecting the right technology to ensure your industrial weighing solutions are accurate and reliable.

-

Explore this link to gain a comprehensive understanding of load cells and their applications in various industries. ↩

-

Find out about the materials used in the elastic body of load cells and their impact on performance. ↩

-

Explore the critical role of sensing elements in load cells and how they contribute to measurement accuracy. ↩

-

Discover the role of strain gauges in load cells and why they are essential for precise measurements. ↩

-

Find out about cost-effective solutions for load cell applications and how to choose the right one. ↩

-

Explore the piezoresistive effect and its crucial role in the functioning of strain gauges. ↩

-

Understand the Wheatstone Bridge configuration and its significance in enhancing load cell measurements. ↩

-

Discover the function of weighing indicators in load cell systems and their role in data display. ↩

[…] same weight to each corner of the platform. The readings should remain consistent. This tests the load cell1's response across the entire surface. Significant variations indicate a potential hardware […]