Are you confused about how different weighing scales operate? You see the old, reliable mechanical scales and the newer, faster digital ones, and the choice isn't always clear.

Mechanical scales measure weight using physical components like springs or levers that move in proportion to the force applied. Digital scales use electronic sensors called load cells to convert the force of weight into an electrical signal, which is then processed to display a precise numerical reading.

Understanding the basics is a good start. But the real difference between these technologies goes far beyond a needle versus a number. For any business that relies on accurate measurements, knowing how they work is critical. Let's look closer at what truly sets them apart, because this knowledge can directly impact your efficiency and bottom line.

What are the differences between mechanical and digital weighing scales?

You need a reliable weight, but different scales can give you different results. This inconsistency can disrupt your inventory, shipping, and production, costing you money. Let's solve this problem.

The biggest differences are accuracy, speed, and features. Digital scales offer high precision and instant results. Mechanical scales are less accurate and slower. Digital scales can also connect to other systems for data tracking, a feature mechanical scales completely lack.

When we talk to clients, the discussion always moves beyond just weighing. It's about what you can do with that weight data. A simple table helps break down the core differences.

| Feature | Mechanical Scale | Digital Scale |

|---|---|---|

| Accuracy | Lower, with errors often around 1%. | High, with errors typically less than 0.1%. |

| Response Time | Slower, requires the needle or beam to settle. | Instant, provides a real-time weight reading. |

| Maintenance | Frequent calibration needed for springs/levers. | Minimal maintenance, long electronic component life. |

| Features | Basic weighing only. | Data output, unit conversion, tare function, connectivity. |

| Cost | Low initial cost. | Higher initial cost, but lower total cost of ownership. |

For a modern business, especially one in the software or tech space, these differences are huge. The accuracy of a digital scale means you can trust your data for financial and inventory purposes. Its speed boosts operational efficiency. But the most important feature is connectivity. The ability to send weight data directly to a computer or network is something a mechanical scale simply cannot do. This transforms a simple scale into a smart data collection1 point for your entire operation.

How do mechanical weighing scales measure weight?

Have you ever wondered about those classic scales with the sliding weights or a large, sweeping dial? They appear simple, but there's some interesting physics at work that makes them function.

Mechanical scales operate on two main principles. A balance beam scale uses a lever and fulcrum to balance an unknown weight with known counterweights. A spring scale uses a spring that stretches or compresses under load, with the displacement corresponding to the weight on a dial.

Let's dive into these two classic mechanisms. They are clever but have significant limitations in a modern industrial environment.

The Balance Beam Principle

You’ve seen this type in a doctor's office. It uses a lever that pivots on a fulcrum. You place the object (or person) on one side, and on the other, you slide known weights along a beam until it balances perfectly horizontally. The position and value of the weights tell you the object's mass. It's a very direct way of comparing an unknown mass to a known one. While very accurate when calibrated, it is extremely slow and requires a skilled operator. It’s not practical for any high-volume process.

The Spring Scale Mechanism

This is more common in simple kitchen or postal scales. Inside is a sturdy spring connected to a gauge or dial. When you put weight on the scale, the spring compresses or stretches. Based on a principle called Hooke's Law, the distance the spring moves is directly proportional to the force applied. The dial is calibrated so that this movement points to the correct weight. I remember from my early days in this industry, the main problem was always "spring fatigue." Over time and with repeated use, springs lose their elasticity, making the scale inaccurate. It becomes a constant battle of recalibration.

What technology is used in digital weighing scales to determine weight?

Digital scales can seem like magic. You place an object on them and an exact weight instantly appears on a screen. But how do they precisely convert physical force into a digital number?

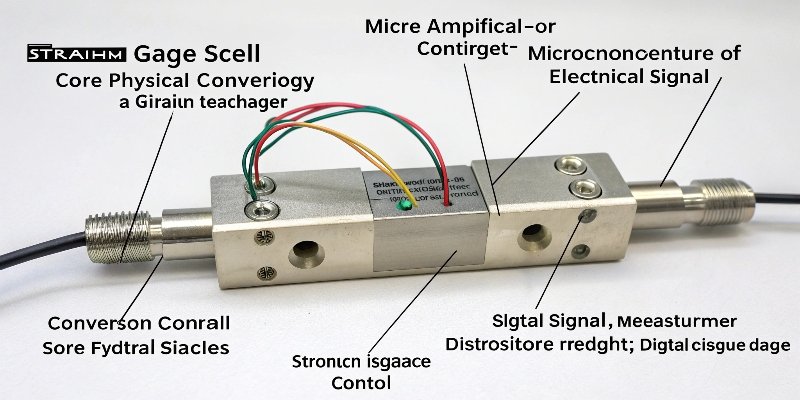

The core technology in most digital scales is the strain gauge load cell. This is a sensor that converts the physical force of weight into a tiny electrical signal. A microcontroller then amplifies, converts, and displays this signal as a precise weight measurement.

The magic is really just brilliant engineering. At Weigherps, our entire business is built around perfecting this technology for industrial use. Here’s how it works from start to finish.

The Role of the Strain Gauge Load Cell

Imagine a small, solid block of metal, usually aluminum or steel. This is the "elastic element" of the load cell. It's designed to bend or deform just a tiny, imperceptible amount when weight is applied. Glued to this block are extremely sensitive sensors called strain gauges. When the block bends, the strain gauges stretch or compress with it. This physical change alters their electrical resistance. This change in resistance is what creates the electrical signal that represents the weight.

From Analog Signal to Digital Readout

The signal from the load cell is incredibly small. The first step is to amplify it so it's clean and readable. Next, an essential component called an Analog-to-Digital Converter (ADC) takes this smooth, continuous signal and translates it into a digital format—ones and zeroes that a computer can understand. Finally, a small onboard computer, or microcontroller, takes this digital data. It performs calculations, compensates for environmental factors like temperature, and sends the final, accurate weight to the LCD or LED screen. This entire process happens in a fraction of a second.

How do you choose between a mechanical and a digital weighing scale?

You're faced with a choice: the old-school mechanical scale or the modern digital one. Making the wrong decision can lead to inefficiency and inaccurate data, hurting your bottom line.

For non-critical home use with no need for precision, a mechanical scale may suffice. For any business, industrial, or scientific application, a digital scale is the clear winner. The decision comes down to your need for accuracy, speed, and data integration.

As someone who helps businesses build weighing solutions, I always ask clients to think about three key areas before they decide.

Consider Your Application's Needs

What are you weighing, and why? If you are just getting a rough estimate for personal use, a mechanical scale might be fine. But if you are in a business environment—managing inventory, calculating shipping costs, or controlling production processes—accuracy is everything. A small error of 1% on a mechanical scale, repeated over thousands of transactions, adds up to a significant financial loss. A digital scale's precision of 0.1% or better protects your profits.

Think about Data and Integration

This is the most important factor for a modern company, especially a software provider. A digital scale isn't just a weighing tool; it's a data-capture device. At Weigherps, our industrial scales2 come with interfaces like RS-232, USB, or wireless IoT capabilities. You can connect them directly to your ERP, inventory management3 software, or custom applications. This automates data logging and eliminates human error. A mechanical scale simply cannot offer this level of integration.

Factor in the Environment and Total Cost

A mechanical scale might seem cheaper at first. However, you must factor in the total cost of ownership4. This includes the cost of frequent recalibration, the downtime it causes, and the financial losses from inaccurate readings. Our digital scales are built to withstand tough industrial environments, require very little maintenance, and provide reliable data for years. They are an investment in the long-term efficiency and profitability of your business.

Conclusion

Mechanical scales are simple tools for basic tasks. But today, digital scales provide the accuracy, speed, and crucial data connectivity that modern businesses need to operate efficiently and grow.

- Explore how modern scales facilitate smart data collection for improved business insights. ↩

- Explore the features of industrial scales that make them suitable for demanding environments. ↩

- Learn how digital scales can streamline inventory management processes for businesses. ↩

- Learn about the total cost of ownership to make informed decisions on scale investments. ↩

[…] its core, a smart scale1 functions much like a traditional digital scale: a load cell2 converts mechanical force into an […]