Are you struggling with inaccurate packaging weights that lead to wasted product and lost profit? This constant inefficiency hurts your bottom line and can damage your brand's reputation over time.

A net weigher uses a high-precision load cell to weigh a product before it enters the package. The packing filler then dispenses this exact amount. This combination ensures every package has the correct weight, boosting accuracy, reducing waste, and increasing production speed and profitability.

You now understand the basic relationship between these three technologies. But the real value comes from knowing how each part works and how they come together to create a powerful, efficient system. Let's dive deeper into the details. Understanding this will help you make the best choice for your production line and see a real return on your investment.

How does net weigh filling technology work in packaging?

Are you wondering how a system can weigh products so accurately while moving so fast? Without understanding the mechanics, you might pick a less effective system and spend more than you need to.

Net weigh filling technology uses a separate weigh bucket to measure the product's weight before dispensing it into the package. The system uses load cells to get an exact weight, ignoring the container's weight. This guarantees that only the product itself is measured for superior accuracy.

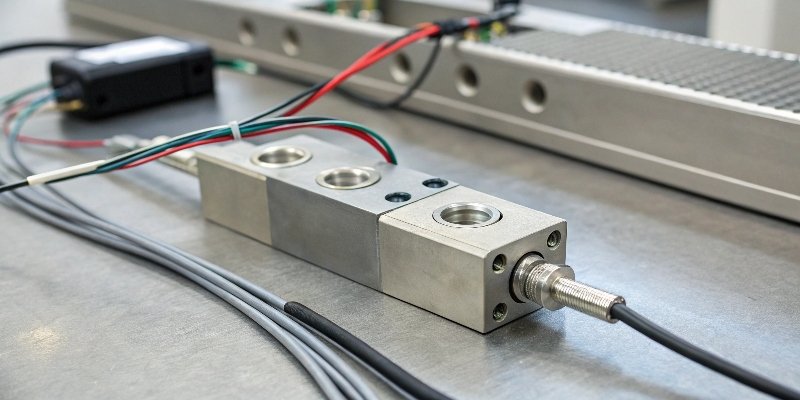

At my company, Weigherps, we design these systems every day. The process is straightforward but very precise. First, the product flows from a large hopper into a smaller weigh bucket1. This weigh bucket sits directly on one or more high-precision load cell2s. The control system is the brain of the operation. It constantly gets information from the load cells3, taking hundreds of measurements per second. Once the load cells detect that the target weight has been reached, the controller instantly closes the gate from the main hopper. The system then opens a gate on the weigh bucket, and the perfectly measured portion of the product drops into its final package below. This method is incredibly accurate, often achieving precision levels of ±0.1% or even better. It completely removes the weight of the packaging from the equation, which is why it’s the best choice for high-value products where every gram counts.

| Step | Action | Purpose |

|---|---|---|

| 1 | Product feeds into weigh bucket | Stage the product for weighing |

| 2 | Load cell measures weight | Continuously monitor the product's net weight |

| 3 | Controller checks target weight | Determine the exact moment to stop the flow |

| 4 | Feed gate closes | Stop product flow instantly at the target weight |

| 5 | Weigh bucket dispenses | Release the accurately weighed product into the package |

What role do load cells play in packing filler systems?

The term "load cell" can sound very technical. You might not see how this small part makes a big difference. But ignoring the quality of your load cell is like trying to build a house on a weak foundation.

Load cells are the core sensors in any modern weighing system. They convert the physical force of weight into an electrical signal. This signal tells the packing filler’s controller the exact weight of the product, allowing it to make precise fills and cuts for consistent results.

A load cell is the true heart of accuracy in a weighing system. I've spent 18 years working with them, and their function is both simple and genius. Inside every load cell is a tiny device called a strain gauge. When you put weight on the load cell, its metal body bends by a microscopic amount. This tiny change in shape stretches or compresses the strain gauge, which changes its electrical resistance. A controller measures this change and converts it into a digital weight reading. It’s this process that provides the data for all decisions. For you as a software vendor, this is critical. A high-quality digital load cell provides clean, reliable data that can be integrated directly with your software, enterprise systems, and IoT platforms. This enables real-time monitoring and powerful analytics. The quality of the load cell directly determines the quality of your data and the accuracy of the entire system.

| Load Cell Type | Best Use Case | Key Feature |

|---|---|---|

| S-Type / Column | Platform scales, general tasks | Versatile and cost-effective for many applications. |

| Canister-Type | Heavy-duty tanks, hoppers, silos | Extremely robust, high capacity for bulk materials. |

| Digital | High-interference or smart factory environments | Contains a microchip for clean signal and anti-jamming. |

What are the benefits of using load cell technology in industrial weighing?

You need to justify investing in new equipment. Are the benefits of advanced load cell technology really worth the cost? Sticking with older, less accurate methods means you are losing money and falling behind your competitors every day.

The primary benefits are accuracy and automation. High accuracy reduces product waste, while automation increases production speed. This technology also ensures consistent quality, which protects your brand and provides valuable data for optimizing your entire production process.

The benefits of modern load cell technology are clear and directly impact your profits. The biggest one is accuracy. A client of mine who packs powdered milk used to have overfill variations of several grams per bag. After we installed a net weigh system with our high-precision load cells, they reduced that error to just ±0.5 grams. Over a year, this saved them over $15,000 in raw material costs alone. Second is efficiency. Automation removes slow, manual steps. Systems we build can accurately fill and seal up to 120 bags per minute, something impossible to achieve by hand. This speed drastically increases your output without needing more staff. Finally, for a business like yours, the data is a goldmine. Our smart weighing systems with digital load cells can connect to your software. This gives you a live look at production rates, batch weights, and efficiency, helping you make smarter business decisions based on real information.

How do net weighers differ from other packing filler technologies?

The market has many types of filling machines. It can be confusing to know which is right for your products. Making the wrong choice can lead to inaccurate fills, messy production lines, and wasted money.

Net weighers measure your product by its exact weight before filling. This is perfect for items where value and accuracy are critical. Other methods, like auger or volumetric fillers, measure by volume, which can be inconsistent if your product's density changes.

The key difference is simple: weight versus volume. A net weigher4 provides an absolute measurement. One kilogram is always one kilogram. Volumetric fillers, on the other hand, measure by space. They fill a container of a certain size and assume the weight is correct. This works well for liquids or free-flowing grains with consistent density. But for products like coffee beans, powders, or snack foods, density can vary. Some coffee beans are larger than others; some powders get compressed in the hopper. Using a volumetric filler for these products leads to inconsistent package weights. One bag might be overfilled, and the next might be underfilled. I have seen many clients switch from volumetric fillers5 to our net weigh systems. They immediately see a reduction in product giveaway and an improvement in package consistency. A net weigher is simply the most reliable way to ensure what's on the label is what's in the bag.

| Filler Technology | Principle of Measurement | Best For | Main Weakness |

|---|---|---|---|

| Net Weigher | Weight (pre-weighed before filling) | High-value powders, irregular solids, snack foods | Can be a larger initial investment. |

| Auger Filler | Volume (a rotating screw dispenses product) | Powders, spices, coffee grounds | Can be inaccurate if product density changes. |

| Volumetric Filler | Volume (a cup of a set size is filled) | Liquids, rice, consistently sized granules | Very inaccurate for compressible or non-uniform items. |

Conclusion

Combining net weighers with quality load cells minimizes waste and boosts speed. This powerful integration is the key to achieving a precise, profitable, and modern automated packaging line.

- Find out how weigh buckets contribute to accurate product measurement before packaging. ↩

- Learn about high-precision load cells and how they improve weighing accuracy in various industries. ↩

- Understand the technology behind load cells and their importance in achieving precise measurements. ↩

- Explore this link to understand how net weighers enhance accuracy and efficiency in packaging. ↩

- Understand the differences between volumetric fillers and net weighers for better packaging choices. ↩

Comments (0)