You need a truly accurate scale, but the spec sheet is a confusing wall of text. Choosing wrong could waste money and ruin your process. Let's make sense of it together.

To buy an accurate scale, look beyond just capacity. Focus on key specs like readability (d), repeatability, and linearity. These numbers reveal the scale's true performance and consistency, ensuring your measurements are always reliable for your specific application.

I've seen many clients over my 18 years in this industry get tripped up by the numbers on a data sheet. They think one number tells the whole story, but it's really about how several specifications work together. Let's dive into the most common points of confusion to make sure you get the right tool for the job, one that delivers value and performance for years to come.

What's the difference between readability and accuracy on a scale's spec sheet?

The spec sheet lists "readability" and implies "accuracy," but they seem the same. Confusing them means you might buy a scale that displays tiny numbers but isn't actually precise. Let's fix that.

Readability is the smallest increment a scale can display (e.g., 0.001g). Accuracy is how close that displayed weight is to the true weight. A scale can have high readability but poor accuracy, so you must consider other factors.

Let's break this down further. When I talk with technical directors, I often use the analogy of a car's speedometer to explain this concept, and it seems to connect well.

Readability (d)

This is like the finest marking on your speedometer. If it shows individual miles per hour (e.g., 55, 56, 57), its readability1 is 1 mph. A digital scale with a readability of 0.1g will show you weight changes in 0.1g increments. It's simply what the screen can show you. It’s a measure of refinement, not correctness.

Accuracy

This is whether your speedometer is telling the truth. If it reads 56 mph, are you actually going 56 mph, or are you really going 53 mph? Accuracy is a broader concept, a combination of several performance factors2 that we will discuss next. A scale is accurate if its reading consistently matches the true weight of an object.

Verification Division (e)

You'll sometimes see another value on spec sheets, e. This is the verification division, which is used for legal trade certifications. It defines the smallest increment3 for which the scale is officially certified. Often, e is 10 times d (e=10d). This means while the scale displays 0.1g increments, it's only certified as accurate in 1g increments. Pay close attention to which value matters for your compliance needs.

Which technical specifications are most critical for ensuring weighing accuracy?

You see a long list of technical specs on the data sheet and feel overwhelmed. Focusing on the wrong ones could lead you to buy a scale that fails under your specific conditions. Let's pinpoint the specs that matter most.

The most critical specs for accuracy are repeatability, linearity, and the calibration method. Repeatability ensures consistent results, linearity guarantees accuracy across the full range, and the right calibration maintains that accuracy over time. These are the big three.

While capacity and readability are important starting points, they don't paint the whole picture of accuracy4. As a manufacturer providing OEM services to global brands, we build scales where these core performance metrics are non-negotiable. Here’s why they are so important.

The Pillars of Accuracy

- Repeatability: This tells you if you'll get the same result every single time you weigh the same object. A scale with poor repeatability5 is unreliable, making your data inconsistent and untrustworthy. It's the foundation of dependable measurement.

- Linearity: This measures the scale's accuracy across its entire weighing range, from zero to its maximum capacity. A common mistake is assuming a scale that's accurate with light objects will also be accurate with heavy ones. Good linearity6 ensures consistent performance no matter the load.

- Calibration Method: How does the scale stay accurate over the long term? An internal auto-calibration feature is incredibly convenient and reliable, as the scale adjusts itself to changes in temperature or location. External calibration requires you to manually check it with certified weights. This gives you more control but requires more work and discipline from your team. Your choice here depends entirely on your workflow and environment.

How do you interpret specs like linearity and repeatability when buying a scale?

You see terms like "linearity: ±0.002g" and "repeatability: ±0.001g." Ignoring these numbers or misinterpreting them could mean buying a scale that is consistently wrong for your needs. Here’s how to read them.

Interpret repeatability and linearity as indicators of the scale's potential error. A smaller number is always better for both. For example, a repeatability of ±0.001g means results for the same item won't vary by more than that amount.

Let's make this practical. When you look at a spec sheet, you’ll see values that tell a clear story about the scale’s quality if you know the language.

Reading the Numbers

- Repeatability (or Standard Deviation): Look for a small value, usually expressed with a "±" symbol (e.g., ±0.1mg). This is the maximum expected difference between consecutive weighings of the same load under the same conditions. If you weigh an item 10 times, all results should fall within this tight range. For high-precision tasks like those required by our software vendor clients, you need a very small repeatability value.

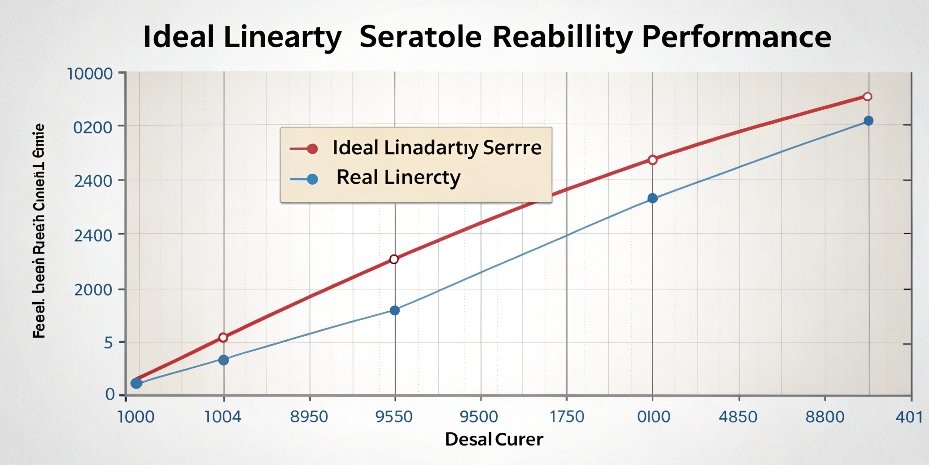

- Linearity Error: This is also shown as a "±" value (e.g., ±0.2mg). It represents the maximum deviation from the true weight at any point in the weighing range. Imagine a perfectly straight line representing ideal accuracy from zero to max capacity. Linearity error is how much the scale’s actual readings stray from that perfect line. Again, a smaller number means a more accurate scale across its entire range.

Here's a quick reference table I give our clients:

| Specification | What it Means For You | What to Look For |

|---|---|---|

| Repeatability | Consistency of your measurements. | The smallest possible ± value. |

| Linearity | Accuracy across the entire weighing range. | The smallest possible ± value. |

What factors on a spec sheet help determine the right scale for your application?

You know the specs, but how do they apply to your specific job? A great laboratory scale will fail in a dusty warehouse, and a rugged industrial scale is complete overkill for a lab. Let's connect the specs to your world.

To choose the right scale, match the application to its specs. For labs, prioritize high readability (e.g., 0.0001g) and low linearity error. For industrial settings, focus on capacity, durability features like IP ratings, and environmental operating ranges.

The perfect scale doesn't exist; the perfect scale for you does. It’s all about context. When a purchasing manager from a software company approaches us, we always ask about their intended use before we even talk about models.

Matching Specs to Your Needs

- For the Laboratory or R&D: If you are measuring small, precise samples for product development, your focus should be on high readability (more decimal places, like 0.0001g) and excellent repeatability and linearity. An internal auto-calibration feature is also a huge time-saver for maintaining accuracy without constant manual effort.

- For Quality Control on the Line: You might need a balance between precision and speed. A readability of 0.001g could be sufficient. Here, you should also look for data ports7 like RS232, USB, or IoT connectivity. These allow you to hook the scale up to a PC or printer for seamless data logging and analysis, which is crucial for modern quality assurance.

- For Industrial and Warehouse Environments: In these tougher settings, capacity and durability are king. Check the scale's maximum capacity to ensure it exceeds your heaviest items. More importantly, look for environmental specifications. An IP rating (e.g., IP65) indicates protection against dust and water ingress. Also, check the operating temperature range on the spec sheet to ensure it matches your facility's conditions, whether it's hot or cold.

Conclusion

By understanding readability, repeatability, and linearity, you can confidently decode any spec sheet. This ensures you invest in a scale that delivers the true accuracy your specific application demands.

-

Understanding readability helps you choose a scale that displays weight increments accurately, ensuring precise measurements. ↩

-

Understanding performance factors will help you evaluate scales effectively for your specific needs. ↩

-

Learning about the smallest increment helps you assess a scale's precision, crucial for accurate measurements. ↩

-

Exploring accuracy will clarify how closely a scale's readings match true weights, crucial for reliable measurements. ↩

-

Learn about repeatability to ensure your scale provides consistent results, vital for trustworthy data. ↩

-

Understanding linearity helps you assess a scale's performance across its entire range, ensuring accurate readings. ↩

-

Learning about data ports will help you select a scale that integrates seamlessly with your data logging systems. ↩

[…] understand a few key terms. It's not just about one number. In my experience, clients often confuse readability1 with overall […]

[…] people use "accuracy" and "readability2" interchangeably, but they are very different. Readability is the smallest increment the […]

[…] to two factors: how much weight it can handle (capacity2) and the smallest increment it can detect (readability3). I always tell my clients to first define the heaviest and lightest samples they need to weigh. […]

[…] a high level of performance and safety. Accuracy isn't just one number. It's about concepts like readability4—the smallest increment a scale can display—and repeatability5, which is getting the same […]