Measuring weight in explosive zones is a major challenge. Standard scales introduce risks and failures. Hydraulic load cells provide a safe, purely mechanical solution for ultimate reliability and safety.

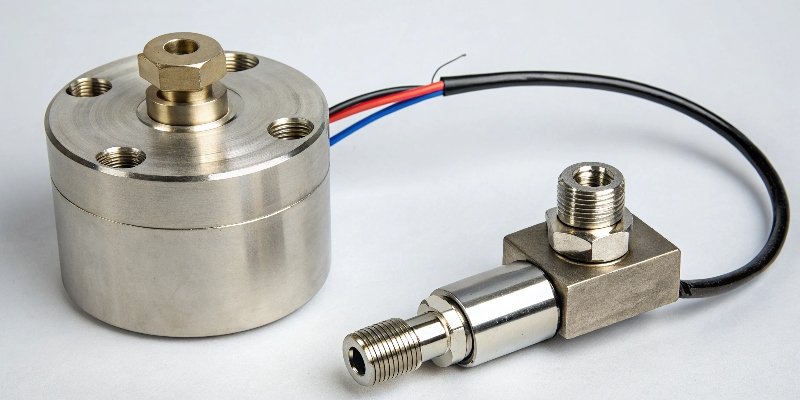

A hydraulic load cell works using Pascal’s Law. An applied force compresses a sealed fluid. This pressure change is then measured by a pressure gauge or transducer, which converts the pressure into a readable weight measurement. It’s an entirely mechanical and safe process.

This simple principle makes hydraulic load cells1 incredibly reliable, especially in places where electronics just can’t survive. But understanding the basic idea is one thing. Seeing how it translates into practical benefits and specific applications is where the real value lies. As an engineer with 18 years in this field, I’ve seen these devices solve some of our clients’ toughest problems. Let’s dig a bit deeper into how they really function and what makes them a smart choice for certain jobs.

How do hydraulic load cells weigh loads?

Confused about how a simple fluid can give precise weight readings? It seems almost like magic. But this "magic" is pure, reliable physics that ensures accurate measurements every time.

Hydraulic load cells weigh loads by converting force into fluid pressure. The force acts on a piston, pressurizing a sealed hydraulic fluid. This pressure is then directly proportional to the applied force, allowing a connected gauge or transducer to display a precise weight reading.

The process is based on a simple physics rule: Pascal’s Law2. This law says that when you apply pressure to a liquid in a sealed container, that pressure spreads out evenly everywhere.

The Force-to-Pressure Conversion

When you put a load on the scale, it presses down on a piston. This piston sits in a sealed chamber full of hydraulic fluid. The force from the load creates pressure in the fluid. Since the chamber is sealed, this pressure increases directly with the force you add.

From Pressure to a Reading

Next, we need to measure this pressure. The pressure goes to a sensing device3, like a Bourdon tube4. This is a curved tube that straightens as pressure builds. Its movement turns a dial to show the weight. For modern systems, we use a pressure transducer. It changes the pressure into an electrical signal (like 4-20mA), which then shows up as a weight on a digital display5. This simple mechanical design is why it’s so reliable.

What are the key features of a hydraulic load cell?

You need a weighing solution that won’t fail in extreme heat, moisture, or explosive dust. Electronics are fragile and risky in these conditions. Hydraulic load cells offer built-in durability and safety.

Key features include their inherent explosion-proof design, as they contain no electronics. They also boast high accuracy (often ≤0.1% FS), excellent overload protection (up to 200%), and a fast response time. This makes them ideal for tough industrial environments where reliability is critical.

Let’s look at the specific features that make these devices stand out for tough jobs. At Weigherps, we help clients choose the right tool, and understanding these features is key.

Unmatched Safety and Durability

Their main benefit is having no internal electronics. This makes them naturally safe for explosive areas and resistant to electrical noise or lightning. They work well in wet, dirty, or corrosive places where electronic load cells would fail. Their strong metal build gives them a high overload capacity. They can often handle 200% of their rated load without breaking.

Performance Comparison

They are tough but also very accurate, with errors usually under 0.1% of their full capacity. To help you decide, here is a simple comparison:

| Load Cell Type | Key Advantage | Best Application |

|---|---|---|

| Hydraulic | Explosion-proof, very durable | Mines, chemical plants, tanks |

| Strain Gauge | Low cost, easy to install | General static weighing |

| Piezoelectric | Extremely fast response | Impact and dynamic force tests |

The best choice depends on your environment and what you need to measure. For tough, high-risk places, hydraulic is often the safest and most reliable option.

Is a load cell active or passive?

Worried about power supplies and complex wiring for your sensors? This adds points of failure. What if your sensor needed no external power to function at its core?

A hydraulic load cell is a passive device. It does not require any external power to sense the force and create a pressure change. However, if you need a digital readout or an electrical signal output (like 4-20mA), an external, powered pressure transducer is required to convert the pressure.

This question can be a bit confusing. The answer depends on which part of the system you mean, and as a manufacturer, we clarify this for our clients all the time.

The Passive Core

A hydraulic load cell by itself is a passive device6. It works mechanically with fluid pressure. It needs no electricity to sense force. If you connect it to a simple dial gauge, the whole system is passive. You can read the weight even if the power is out. This simplicity is a big plus for reliability, especially in remote or dangerous areas.

Adding Active Parts

The system becomes ‘active’ when you add a part that needs power. In modern industry, you often want a digital display or to send weight data to a control system. To do this, you use a pressure transducer. It changes the hydraulic pressure into an electrical signal. This transducer requires power, making that part of the system active. So, the load cell is passive, but the output system is often active.

What is the lifespan of a load cell?

Constantly replacing failed load cells is expensive and causes downtime. You need a device built to last. The lifespan of a load cell can vary wildly based on its type and use.

The lifespan of a hydraulic load cell is exceptionally long, often lasting for decades. Since they have no electronic components or strain gauges to fatigue or drift, they are not prone to the same wear and tear as other types. Their lifespan is mainly determined by the integrity of their seals.

A load cell’s lifespan is very important for its total cost of ownership. For hydraulic load cells, the news is excellent, and it’s a point we emphasize with our customers.

Built to Last

Hydraulic load cells are designed for a long life. They use a simple mechanical system and have no sensitive electronics. So, they don’t suffer from electronic drift or fatigue as strain gauge load cells do. It’s common to see hydraulic systems still working perfectly after 20 or even 30 years. The main body is just a strong piece of metal. As long as it’s not damaged or rusted, it will keep working.

Factors Affecting Lifespan

The main thing that limits a hydraulic load cell’s life is its seals7. Extreme temperatures or chemicals might wear down seals over time, causing fluid leaks. However, these are made from very tough materials. Constant overloading past its design limit could also cause damage. But unlike a strain gauge cell, which has a finite fatigue life, a properly used hydraulic cell will last much, much longer.

Conclusion

Hydraulic load cells use simple physics to provide safe, durable, and accurate weighing. They are the top choice for harsh environments where other scales fail, ensuring long-term reliability.

-

Explore this link to understand the mechanics and advantages of hydraulic load cells in various applications. ↩

-

Learn about Pascal’s Law and its significance in the functioning of hydraulic load cells. ↩

-

Find out about the various sensing devices that enhance the functionality of hydraulic load cells. ↩

-

Discover the function of Bourdon tubes in measuring pressure and their application in load cells. ↩

-

Learn how digital displays enhance the functionality of hydraulic load cells in modern applications. ↩

-

Understand the concept of passive devices and their advantages in hydraulic load cell systems. ↩

-

Understand the importance of seals in maintaining the integrity and performance of hydraulic load cells. ↩

Comments (0)