Is your scale's data unreliable? Inaccurate readings can corrupt your entire system. The load cell is the heart of your scale, directly controlling its performance and data integrity.

A load cell is a sensor that converts weight into a measurable electrical signal. Its quality dictates the scale's accuracy, resolution, and reliability. A superior load cell provides precise, consistent data, while a poor one introduces errors and instability, directly undermining your system's overall performance.

The load cell1 is more than just a piece of hardware; it is the first and most critical link in your entire data chain. As a software provider, you understand the principle of "garbage in, garbage out." The most elegant software cannot correct flawed data coming from a faulty or low-quality sensor. The reliability of your final output begins with the physical measurement. But how do you tell one load cell from another, and what factors truly make a difference in real-world applications? Let's explore the details that ensure you get clean, trustworthy data from the very start.

How do different types of load cells impact a scale's accuracy and cost?

Choosing a load cell feels complicated. You need high accuracy but must also manage costs. Making the wrong choice can lead to poor performance or a wasted budget.

Different load cell types, mainly strain gauge, offer varying levels of accuracy and cost. Strain gauge cells are the industry standard, providing the best balance of performance and value. High-precision models cost more but guarantee the data integrity your software requires for reliable operation.

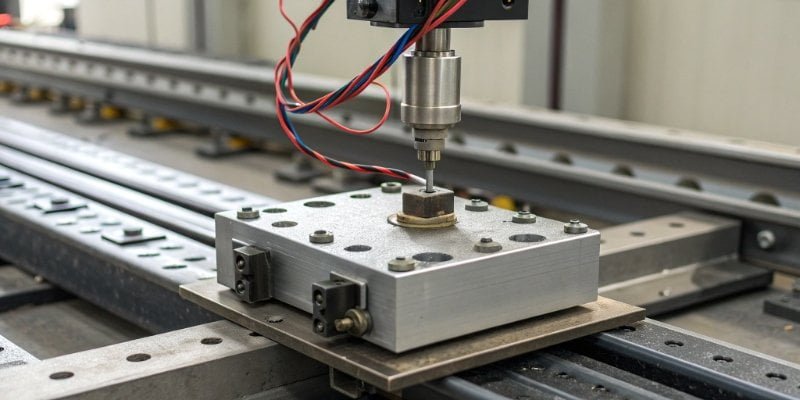

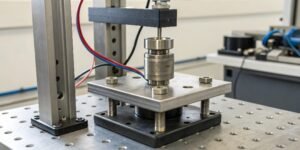

At its core, a strain gauge2 load cell works by converting force into an electrical signal. When a weight is placed on the scale, a metal element inside the load cell, known as the elastic body, deforms very slightly. This deformation changes the electrical resistance of strain gauges attached to it. A circuit called a Wheatstone bridge3 detects this tiny change and turns it into a stable, usable voltage signal, typically in the 0-20mV range. This is the raw data your system will use. For software vendors, the quality of this initial signal is everything. A higher-quality sensor, like the HBM Z6 series we often recommend, can have a non-linearity error4 below ±0.03%, ensuring extremely high precision. Lower-cost cells may have higher error rates, introducing noise that your software might misinterpret.

Here is a simple breakdown:

| Load Cell Type | Typical Accuracy | Relative Cost | Best For |

|---|---|---|---|

| Aluminum Single-Point | Good (±0.05%) | Low | Bench scales, retail scales, dry environments |

| Alloy Steel Shear Beam | Very Good (±0.03%) | Medium | Floor scales, tank weighing, general industrial |

| Stainless Steel S-Type | Excellent (±0.02%) | High | Hopper scales, tension applications, harsh areas |

Investing a bit more in a better load cell is often the most cost-effective decision. It prevents data issues that can cause major headaches for your software and your end-users.

What are the common signs that a faulty load cell is causing inaccurate readings?

Your scale readings are fluctuating wildly, and you can no longer trust the data. A faulty load cell could be the hidden culprit, silently corrupting every measurement your system takes.

Common signs of a faulty load cell include readings that drift over time, jump suddenly, or fail to return to zero after a load is removed. Inconsistent measurements for the same object are also a clear red flag. These issues mean the sensor is failing.

In my 18 years of manufacturing scales, I've seen how a failing load cell can disrupt an entire operation. The signs are usually clear if you know what to look for. Diagnosing them quickly can save your clients significant time and money. Here are the main symptoms we tell our partners to watch out for.

Drifting Readings

This is when the weight display slowly creeps up or down, even with nothing on the scale. I once helped a client whose automated bagging system was consistently overfilling products. The problem was a damaged load cell whose zero point kept drifting upward throughout the day, causing the system to miscalculate every fill.

Inconsistent or Non-Repeatable Results

You place a 10kg test weight on the scale, and it reads 10.02kg. You remove it and place it back on, and it reads 10.08kg. Then 9.95kg. This lack of repeatability points directly to a failing or damaged load cell that can no longer provide a consistent output.

Failure to Return to Zero

When you remove all weight from the scale, the display should read "0.00". If it consistently shows a positive or negative value, the load cell may have been permanently deformed from an overload or is suffering from internal electronic failure.

If you see these signs, first check for debris under the scale platform. If it's clear, the load cell is the most likely cause. For our OEM partners, we provide clear testing protocols to diagnose these issues with a simple multimeter.

How do environmental factors like temperature and moisture affect load cell performance?

Your scale works perfectly in the workshop but starts giving strange readings on the factory floor. Overlooked environmental factors like heat and humidity can quietly sabotage your load cell's accuracy.

Temperature changes cause a load cell’s metal to expand or contract, which can alter its readings. Moisture and dust can lead to corrosion or short circuits. High-quality load cells use built-in temperature compensation and are sealed with an IP rating (e.g., IP67) for protection.

A load cell is a precision instrument, and its performance is sensitive to its surroundings. You can't expect a basic load cell to perform well in a harsh industrial setting. As a systems integrator, choosing a sensor that can handle the end-user's environment is crucial for long-term reliability.

The Impact of Temperature

As the temperature rises, metal expands. As it cools, it contracts. These tiny physical changes in the load cell's body can affect its electrical resistance, creating false readings. This is called thermal drift. To solve this, quality load cells have temperature compensation5 built-in. This is a small network of resistors that adjusts the output signal to counteract temperature effects. This ensures a stable and accurate reading whether your scale is in a cold warehouse or a hot production line.

The Threat of Moisture and Dust

Moisture is the enemy of electronics. In environments like food processing plants with frequent washdowns, or in dusty agricultural settings, protection is not optional. This is where IP (Ingress Protection) ratings become critical. An IP67-rated load cell, for instance, is completely dust-tight and can be submerged in up to 1 meter of water for 30 minutes without issue. For our clients with equipment in these industries, we always recommend stainless steel load cell6s with at least an IP67 rating to prevent corrosion and failure.

Why is the material of a load cell (e.g., stainless steel vs. aluminum) critical for its application?

You might think all load cells are just blocks of metal. But the material matters tremendously. Choosing the wrong one can lead to early failure, corrosion, and inaccurate data.

A load cell's material determines its durability, corrosion resistance, and operational lifespan. Aluminum is light and cost-effective for clean, dry areas. Stainless steel offers superior ruggedness and rust protection, making it essential for wet, hygienic, or corrosive environments.

The material of a load cell is not just a detail; it's a fundamental design choice that defines where and how the scale can be used reliably. Matching the material to the application prevents premature failure and ensures the long-term accuracy your software depends on. As a manufacturer, we guide our clients to make the right choice to protect their investment and reputation. The total cost of ownership is far more important than the initial purchase price.

Here's how the common materials compare:

| Material | Key Advantage | Main Disadvantage | Ideal Application |

|---|---|---|---|

| Aluminum Alloy | Cost-effective, lightweight | Prone to corrosion, less durable | Retail scales, postal scales, laboratory balances in dry, controlled environments. |

| Alloy Steel | Strong, durable, good value | Requires coating (e.g., nickel plating) to resist rust | General industrial use, floor scales, tank weighing in mostly dry areas. |

| Stainless Steel | Excellent corrosion resistance7, very durable, hygienic | Higher cost | Food processing, pharmaceutical, chemical plants, and any application with frequent washdowns or exposure to corrosive materials. |

For many of our partners providing solutions for factories, choosing between alloy steel and stainless steel is a key decision. If the scale will be washed down daily, stainless steel is the only reliable option. An aluminum cell would fail quickly, and a plated alloy steel cell would eventually corrode. Choosing the right material from the start ensures your weighing system will last.

Conclusion

The load cell is your scale's core. Its type, quality, material, and environmental protection directly determine the accuracy and reliability of the data your system depends on.

-

Understanding load cells is crucial for ensuring accurate weight measurements in various applications. ↩

-

Learn about strain gauge technology and why it's the industry standard for load cells. ↩

-

Gain insights into the Wheatstone bridge's role in measuring weight accurately. ↩

-

Understanding non-linearity error helps in selecting high-precision load cells for accurate measurements. ↩

-

Learn how temperature compensation ensures accurate readings despite environmental changes. ↩

-

Understand why stainless steel is preferred for durability and corrosion resistance in tough conditions. ↩

-

Discover how corrosion resistance affects the longevity and reliability of load cells. ↩

[…] getting inside the load cell is a common problem. It causes short circuits and corrosion. A high IP rating5 (like IP67 or IP68) is essential for wet […]