Are you curious about how scales work but find the science confusing? Technical jargon can be overwhelming. We'll break down the core principles into simple, easy-to-understand concepts for you.

Modern scales use sensors, often called load cells, to convert the force of an object's weight into an electrical signal. This signal is then processed, converted to a digital value, and displayed as a weight measurement. It essentially translates physical force into a readable number.

Over our 18 years as an industrial scale manufacturer, we've seen technology evolve dramatically. But the basic principles of measurement have stayed the same. To truly appreciate modern, high-tech scales, you need to understand the fundamentals. It's a journey from basic physics to advanced electronics. Let's start with the most fundamental question.

What is the basic principle behind how weighing scales work?

Do you sometimes mix up the words mass and weight? This common confusion makes it hard to grasp how scales really measure anything. Let's clarify this and show you the simple process scales use.

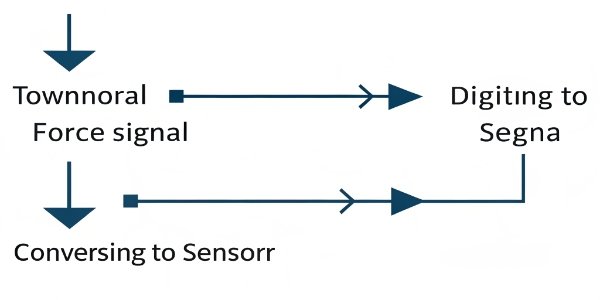

Scales measure weight, which is the force of gravity on an object. This force deforms a component inside the scale. A sensor detects this tiny change and converts it into an electrical signal. This signal is then translated into a mass reading, like kilograms or pounds.

To really get it, you need to dive a little deeper into the science. The whole process is a clever conversion of physical force into a number we can read. It starts with a key distinction in physics and flows through a precise electronic workflow. As a hobbyist or student, understanding this is your first step to mastering weighing technology. I remember when I first started in this industry, getting this concept right was a real 'aha!' moment.

Mass vs. Weight: The Core Distinction

First, let's clear up the difference between mass and weight1. They are not the same thing.

- Mass is the amount of matter in an object. It is constant no matter where you are in the universe. Its standard unit is the kilogram (kg).

- Weight is the force exerted on an object by gravity. Your weight would be different on the Moon than on Earth because the Moon's gravity is weaker. Its unit is the Newton (N).

A weighing scale is technically a "mass measuring" device, but it does this by measuring weight. It uses the known force of Earth's gravity as a constant to calculate mass from the weight it detects.

The Sensor's Workflow: From Force to Signal

Here is the step-by-step process that happens inside most modern electronic scales:

| Step | Action | Description |

|---|---|---|

| 1 | Apply Force | You place an object on the scale. Its weight (force) pushes down. |

| 2 | Elastic Deformation | This force causes a metal element, called an elastic body or load beam, to bend very slightly. |

| 3 | Resistance Change | A sensor called a strain gauge2, which is glued to this metal, gets stretched or compressed. This changes its electrical resistance. |

| 4 | Voltage Output | The change in resistance is detected by a circuit (a Wheatstone bridge3), which outputs a tiny voltage signal that is directly proportional to the weight. |

This small voltage is the raw data that the scale's brain will use to figure out the final weight.

What is the difference between mechanical and electronic weighing technology?

You've probably seen old spring scales at a market and sleek digital scales in a lab. They both tell you the weight, but the technology inside is completely different. Let's compare them.

Mechanical scales use physical components like springs or balancing levers and a moving pointer to show weight. Electronic scales use sensors to create an electrical signal, which is digitally processed for a highly accurate reading on an electronic display. They are faster and more precise.

We've produced countless electronic scales, but we still respect the simple genius of mechanical designs. However, the demands of modern industry and science for precision, speed, and data integration made the shift to electronic technology necessary. Understanding both helps you appreciate why one has almost completely replaced the other in professional settings.

The Mechanical Approach: Levers and Springs

Mechanical scales are the classic weighing instruments. They operate on two main principles:

- Balance Scales: These work by comparing an unknown mass to a known mass. Think of the classic scales of justice with two pans. They are very accurate but slow to use.

- Spring Scales: These use a spring that stretches or compresses according to Hooke's Law. The distance it moves is proportional to the weight. A pointer on a dial shows the reading.

| Pros of Mechanical Scales | Cons of Mechanical Scales |

|---|---|

| No electricity needed | Lower accuracy and precision |

| Often very durable and robust | Moving parts wear out over time |

| Simple to understand and operate | Prone to errors from friction |

| Not easily integrated with digital systems |

The Electronic Revolution: Sensors and Processors

Electronic scales represent a huge leap forward. As we discussed, they convert force into an electronic signal. This digital approach brings many advantages that are essential today. At Weigherps, everything we build is based on this principle, as it allows for the quality and features our clients demand.

| Pros of Electronic Scales | Cons of Electronic Scales |

|---|---|

| High accuracy and resolution | Requires a power source (battery or mains) |

| Fast and stable readings | Can be sensitive to electronic interference |

| Extra features (tare, unit conversion, counting) | More complex internal components |

| Easily connects to computers and networks (IoT) | Can be damaged by overloading or impact |

What are the main types of sensors used in modern digital scales?

Ever wondered what that magic component inside a digital scale is? The sensor is the heart of the scale, but it's often a "black box" to the user. Let's open it up.

The most common sensor is the strain gauge load cell. It measures the tiny bending of a metal structure under weight. Other types include capacitive sensors, which detect changes in capacitance, and piezoelectric sensors, which generate a voltage when pressure is applied for dynamic weighing.

Choosing the right sensor is critical in my line of work. The application determines everything. For a heavy-duty truck scale, you need a robust strain gauge. For a super-sensitive lab balance, a different technology might be used. For hobbyists, the strain gauge is what you'll encounter most often.

Strain Gauge Load Cells: The Industry Standard

This is the workhorse of the weighing world. A strain gauge is a very fine wire or foil set up in a grid pattern. When the metal body it's attached to bends, the gauge's electrical resistance changes.

- How it Works: Multiple strain gauges are arranged in a Wheatstone bridge circuit to measure this resistance change with extreme precision and to cancel out temperature effects.

- Why it's Popular: Strain gauge load cells4 offer an excellent balance of accuracy, reliability, and cost. They can be made in all shapes and sizes, making them suitable for everything from bathroom scales to massive industrial silos.

Other Important Sensor Technologies

While the strain gauge dominates, other sensors are used for specific applications.

| Sensor Type | Working Principle | Typical Application |

|---|---|---|

| Capacitive | Two metal plates move closer or further apart with weight, changing the capacitance between them. | Low-profile scales, retail scales, touch-sensitive controls. |

| Piezoelectric | A crystal (like quartz) generates an electrical charge when compressed by a force. | Dynamic weighing, force measurement, pressure sensors. |

| Electromagnetic Force Restoration (EMFR) | An electromagnet generates a force to counteract the weight, and the current needed is measured. | High-precision analytical and laboratory balances. |

What factors affect the accuracy of a weighing instrument?

Have you ever stepped on a bathroom scale, stepped off, and gotten a different reading a second later? It's frustrating when you can't trust your measurements. Let's look at what causes these errors.

A scale's accuracy is affected by environmental factors like temperature changes and vibrations. Physical factors include sensor aging or damage. Electrical issues like power fluctuations can also cause errors. Regular calibration is essential to correct for these and ensure consistent, reliable readings.

In our quality control department, every single scale we produce is tested for accuracy under various conditions. We know that in the real world, a scale won’t always be in a perfect lab environment. Understanding what can go wrong is just as important as knowing how the scale works.

Environmental and External Influences

The environment around a scale can have a big impact on its readings.

- Temperature: Materials expand and contract with heat and cold. This can affect the sensor and electronics. High-precision scales have temperature compensation5 built in, but sudden changes can still cause drift. For best results, use scales in a stable temperature environment (e.g., 20°C ±5°C).

- Vibrations: A shaky floor from nearby machinery or even heavy footsteps can create "noise" in the reading, making it unstable.

- Air Currents: For very sensitive scales (measuring in milligrams), even a breeze from an air conditioner or a person breathing nearby can affect the result. That's why they often have a draft shield6.

Instrument and Operational Errors

The scale itself can also be a source of error.

| Error Source | Description | How to Fix or Prevent |

|---|---|---|

| Calibration Failure | The scale's internal calculation is no longer accurate. This is the most common cause of bad readings. | Perform regular calibration with certified standard weights. |

| Sensor Aging / Fatigue | Over time and with repeated use, the elastic properties of the load cell can change slightly. | This is unavoidable, but regular calibration corrects for it. |

| Unstable Power | Fluctuations in the voltage from a wall outlet or a dying battery can affect the electronic signals. | Use a stable power source or make sure batteries are fresh. |

| Improper Loading | Placing the object off-center can cause incorrect readings on some scales. | Always place the item in the center of the weighing pan. |

Conclusion

Understanding these core principles, from sensors to calibration, empowers you to use scales more effectively and appreciate the science behind every accurate measurement you take.

-

Clarify the distinction between mass and weight to enhance your understanding of how scales function. ↩

-

Gain insights into strain gauges, the heart of modern weighing technology, and their applications. ↩

-

Understand the Wheatstone bridge circuit's significance in measuring weight accurately. ↩

-

Explore this resource to understand the technology behind load cells, essential for modern weighing scales. ↩

-

Learn about temperature compensation techniques that enhance the accuracy of sensitive scales. ↩

-

Discover how draft shields protect sensitive scales from environmental influences. ↩

Comments (0)