Ever wonder what happens inside a scale when you weigh something? The process seems simple, but the science behind that instant number can be a mystery.

A weighing scale works by converting the force of an object's weight into an electrical signal. Load cell sensors measure this force, and a microcontroller processes the signal, calculates the final weight, and shows it on a digital display for a fast, accurate reading.

That's the basic idea. But there is much more to it. After 18 years of manufacturing industrial scales1, I’ve learned that the magic is in the details. How these components work together determines a scale's accuracy and reliability. Let's dig deeper into the mechanism, understand why readings sometimes change, and see what makes modern scales so precise. This knowledge will help you choose the best equipment for your business needs.

What is the mechanism of a weight scale?

Are you unsure about the core technology inside your weighing equipment? This uncertainty can make it hard to choose the right scale or troubleshoot problems when they appear.

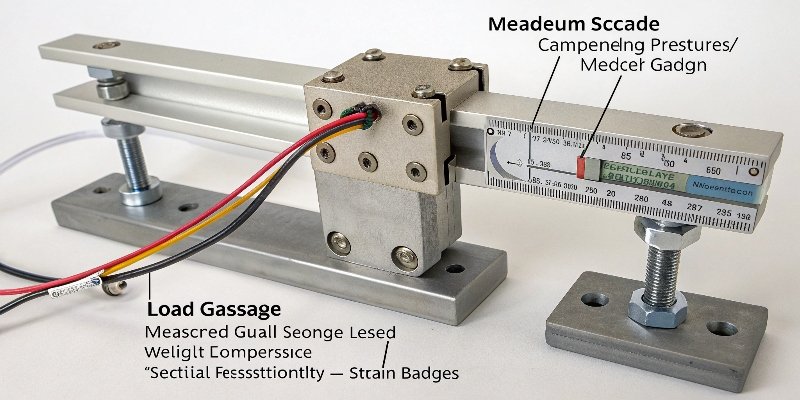

The main mechanism of a modern scale is a load cell sensor. This sensor has strain gauges attached to a flexible metal structure. When you apply weight, the structure bends, which stretches or compresses the strain gauges. This changes their electrical resistance, which is then measured.

Let's dive deeper into how this works. At our company, we rely on this principle for almost every scale we build. The process is both brilliantly simple and incredibly precise. It all starts with a component called a strain gauge.

The Role of the Strain Gauge

A strain gauge is essentially a flexible electrical conductor. It's designed in a zigzag pattern and bonded firmly to a flexible piece of metal, known as the load cell. When you place an object on the scale, its weight applies a force that slightly deforms the load cell. This deformation, even if it's microscopic, stretches or compresses the strain gauge. As the conductor's shape changes, so does its electrical resistance2. A longer, thinner wire has more resistance, while a shorter, thicker one has less. This tiny change in resistance is directly proportional to the amount of force applied.

The Wheatstone Bridge Circuit

So, how do we measure such a tiny change in resistance? We use a configuration called a Wheatstone bridge3. This circuit uses four strain gauges4 arranged in a diamond shape. When there is no weight on the scale, the bridge is "balanced," meaning the voltage across it is zero. But when weight is applied, some gauges are stretched and others are compressed. This unbalances the bridge and creates a very small, measurable voltage difference. This voltage is the raw analog signal that represents the weight on the scale.

Why does the scale change when I move it?

It can be very frustrating when your scale gives you different readings in different spots. This inconsistency can damage your data's accuracy and make you lose trust in your equipment.

Moving a scale can change its reading because of uneven surfaces and the need for recalibration. An unlevel floor distributes weight unevenly across the sensors, causing errors. The shock from movement can also affect sensitive internal components, requiring the scale to be recalibrated or "tared."

I've seen this issue many times with clients. A scale is a precision instrument, and its environment matters a lot. Let's break down the main reasons for these shifting readings.

The Importance of a Level Surface

Most scales, especially household scales or bench scales, use multiple load cells—often one at each corner. The scale’s processor assumes the weight is distributed evenly. If you place the scale on an unlevel surface, one or two load cells will bear more force than the others. This imbalance leads to an inaccurate reading. For this reason, many industrial scales come with adjustable feet and a bubble level indicator. You must ensure the scale is perfectly level before use to get reliable measurements.

Environmental Factors

The environment where you use the scale can also cause readings to fluctuate.

- Temperature: Materials expand when they get warm and shrink when they get cold. This thermal expansion can affect the load cell and strain gauges, altering their electrical resistance and causing reading drift. As manufacturers, we solve this by building temperature compensation5 into our microprocessors. The software adjusts the calculation based on the ambient temperature.

- Vibrations: Nearby heavy machinery, foot traffic, or even air currents can create vibrations that interfere with the load cell's ability to get a stable reading. This is why high-precision scales often have draft shields, and industrial scales are built with heavy-duty materials to dampen vibrations. Anytime you move a scale, it's best to let it settle and then use the Tare function6 to zero it out.

How do digital weighing scales work?

You know that digital scales are highly accurate, but do you know how they achieve that precision? Not understanding the process makes it hard to appreciate the advanced technology inside.

Digital scales work by converting an analog electrical signal from the load cell into a digital value. An Analog-to-Digital Converter (ADC) performs this conversion. A microprocessor then takes this digital data, filters it, runs calculations, and displays the final, highly precise weight.

This digital processing is what separates modern scales from old mechanical ones. It turns a tiny physical change into a reliable, readable number. As a tech-focused company, we put a lot of engineering effort into this part of the process.

From Analog Signal to Digital Data

The voltage signal produced by the Wheatstone bridge is extremely weak, often just a few microvolts. It's also an analog signal, which means it's a continuous wave. Computers can't work with analog data directly. So, the first step is to amplify this weak signal to a more usable level. After amplification, the signal goes to an Analog-to-Digital Converter (ADC). The ADC measures the analog signal thousands of times per second and converts each measurement into a digital value—a series of 1s and 0s that a computer can understand. The higher the resolution of the ADC, the more precise the final weight reading will be.

The Microcontroller's Job

Once the weight data is in digital format, the scale's "brain"—the microcontroller7—takes over. This tiny computer is programmed to perform several crucial tasks.

- Filtering: It filters out digital "noise" caused by vibrations or electrical interference to ensure the reading is stable.

- Compensation: It applies corrections for environmental factors, like temperature changes, using data from other sensors.

- Calculation: It uses the factory calibration data to convert the raw digital value into a standard unit of weight, like kilograms (kg) or pounds (lbs).

- Functions: It runs user-facing features, such as the Tare function6 (to zero out a container's weight), unit switching, or parts counting.

This sophisticated processing happens in a fraction of a second, giving you an accurate weight almost instantly.

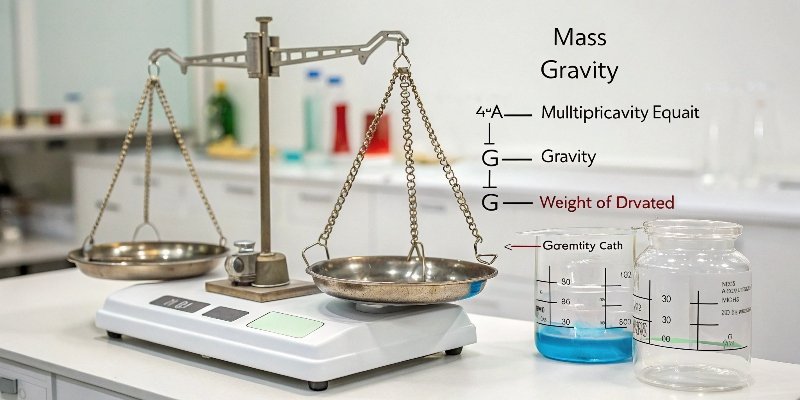

How do weighing machines measure weight?

People often use the terms weight and mass as if they are the same, which can lead to confusion. This misunderstanding can make you wonder what your scale is actually measuring.

Weighing machines measure weight, which is the force of gravity on an object's mass. They use load cells to detect this downward force. The machine is then calibrated to translate this force measurement into a reading that represents mass, such as kilograms or pounds.

Putting everything together, the entire process is a perfect blend of physics and modern electronics. The machine doesn't see "mass"; it feels "force." But it's smart enough to give us the number we actually need.

The Complete Measurement Process

Let's walk through the entire journey from start to finish, from placing an item on the scale to seeing the result.

- Force Application: You place an object on the scale platform. Gravity pulls the object's mass downward, creating a force.

- Mechanical Bending: This force is transferred to one or more load cells, causing them to bend by a microscopic amount.

- Electrical Signal: The strain gauges inside the load cells stretch or compress, changing their resistance and creating a tiny voltage signal via the Wheatstone bridge.

- Digital Conversion: This analog signal is amplified and converted into a digital signal by the ADC.

- Processing & Calculation: The microcontroller cleans the signal, applies calibration and temperature adjustments, and calculates the final weight.

- Display: The result is immediately shown on the LCD or OLED screen8 in the unit of your choice.

Industrial vs. Household Scales

While the core principle is the same, the application of this technology varies greatly. As an industrial scale manufacturer, our products must meet very different demands than a simple bathroom scale.

| Feature | Household Scale | Industrial Scale |

|---|---|---|

| Environment | Stable, indoor locations | Harsh, dusty, wet, and high-vibration factory floors |

| Durability | Plastic or glass construction | Robust, often made of stainless steel (IP67/IP68) |

| Capacity | Low (e.g., up to 200 kg) | High (from kilograms to several tons) |

| Features | Basic weighing, Tare | Parts counting, dynamic weighing, IoT connectivity |

| Data Integration | None or basic Bluetooth | Connects to PLCs, ERP systems, and cloud platforms |

Our industrial scales are designed for high-speed, dynamic weighing9 and can withstand harsh conditions while providing data that integrates directly into a client's workflow. This is where we empower businesses to improve their production, sales, and profits.

Conclusion

In short, a scale translates physical force into a clean digital signal using sensors, converters, and processors. Understanding this helps you appreciate the technology and choose the right scale.

-

Explore the differences between industrial and household scales to choose the right one for your needs. ↩

-

Learn about electrical resistance and its critical role in the functioning of weighing scales. ↩

-

Delve into the Wheatstone bridge circuit and its significance in weight measurement. ↩

-

Understand the importance of strain gauges in measuring weight accurately. ↩

-

Learn how temperature compensation improves the reliability of weight readings. ↩

-

Find out how the Tare function helps in obtaining accurate weight measurements. ↩ ↩

-

Discover how microcontrollers enhance the precision and functionality of weighing scales. ↩

-

Discover the advantages of LCD and OLED screens in displaying weight measurements. ↩

-

Learn about dynamic weighing and its importance in industrial applications. ↩

[…] is Digitized: A specialized chip, often an Analog-to-Digital Converter (ADC)3 like the HX711, measures this tiny change in resistance. It converts the analog signal into a […]

[…] change in resistance is detected by a circuit (a Wheatstone bridge3), which outputs a tiny voltage signal that is directly proportional to the […]