Struggling with scales that break down too soon? The constant replacement costs and inaccurate readings are frustrating. I know how important a reliable scale is for any operation.

A good digital scale's lifespan varies greatly. Consumer scales might last 2-5 years. High-quality industrial scales, with proper maintenance, can reliably function for 10-15 years or even longer. Key factors are build quality, usage, and environment.

The difference between a few years and a decade is huge, especially in a business setting. Understanding what affects a scale's life is key to making a smart investment. Let's explore this further to see why some scales stand the test of time while others fail quickly.

How long does a digital scale last?

Confused by the wide range of lifespans for digital scales? It's hard to budget when one scale dies in a year and another keeps going. Let’s clarify this for you.

The lifespan of a digital scale depends on its type. A typical commercial scale, like one for home use, may last a few years. An industrial scale, built for heavy-duty use, is designed to last over a decade with proper care.

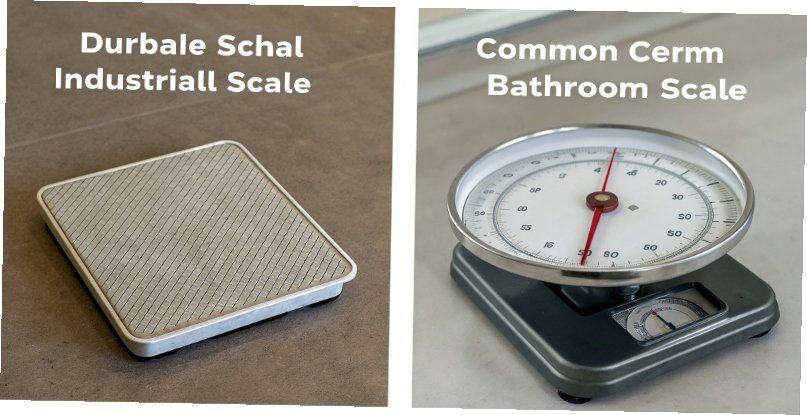

The biggest difference comes down to purpose. I've spent 18 years in this industry, and I see two main categories: commercial scales1 and industrial scales2. Commercial scales are what most people use at home. Industrial scales are built for business.

Built for Different Worlds

The materials tell the whole story. An industrial scale often uses heavy-gauge stainless steel and has protected internal parts. It’s made to handle tough conditions. A commercial scale usually has a plastic body. It works fine in a kitchen or bathroom but not in a busy warehouse. The environment where you use the scale matters a lot. For instance, many of our clients in the food industry need scales that can handle daily washdowns. Our IP67-rated scales3 are sealed against water and dust. They have worked for over eight years in wet facilities where a normal scale would fail in a week.

Designed for Different Loads

An industrial scale is also built for constant and heavy use. Its load cells4 are robust and can handle repeated heavy loads without losing accuracy5. A commercial scale is designed for light, infrequent use. If you put too much weight on it, you can permanently damage it. It’s about choosing the right tool for the job.

How often should you replace weighing scales?

Wondering if it's time to replace your scale? Using an old, unreliable scale can lead to costly errors in business. Let's set a clear timeline for you.

Replace scales when they show consistent inaccuracies, require frequent repairs, or fail calibration tests. For businesses, replacing a scale every 7-10 years is a wise strategy to ensure reliability and access to newer technology.

You don't have to wait for a scale to break completely before replacing it. There are clear signs that tell you it's time for an upgrade. Paying attention to these signs can save you a lot of trouble.

Key Signs for Replacement

First, look for calibration failures. If your scale cannot hold its calibration, it is no longer reliable. Second, watch for inconsistent readings. If you weigh the same item three times and get three different numbers, the load cell is probably failing. Third, check for physical damage. Cracks or dents can harm the sensitive parts inside. Finally, consider its features. An older scale might not connect to your software systems6. Many of our software vendor clients need scales with modern IoT capabilities. Upgrading gives them better data and a smoother workflow. It’s not just about getting a new tool; it’s about improving your whole process.

General Replacement Guidelines

| Scale Type | Usage Level | Recommended Replacement Cycle |

|---|---|---|

| Commercial (Home) | Light, Daily | 3-5 years or upon failure |

| Commercial (Retail) | Moderate, Daily | 5-7 years |

| Industrial | Heavy, Constant | 7-15+ years (with maintenance) |

Are old scales not accurate?

Are you still trusting an old scale? These devices can lose their accuracy over time without you even realizing it. This can lead to incorrect measurements, which is a big problem.

Not always. An old but well-maintained, high-quality industrial scale can remain accurate for many years with regular calibration. However, all scales experience some wear and tear over time which can affect accuracy if not serviced.

Age itself doesn't make a scale inaccurate. The real factors are its quality and how well you take care of it. A cheap, new scale can be less accurate than a 10-year-old industrial scale that has been properly maintained.

Understanding Component Drift

The core of a digital scale7 is the load cell. Inside the load cell are tiny sensors that can change, or "drift," over time. This means their electronic signal might change even if the weight on the scale is the same. Many things can cause this drift, like big changes in temperature or constant shaking. This is why we design our industrial scales to be very stable. We use high-quality components that resist these changes. It ensures the scale provides accurate readings for a long, long time.

The Role of Calibration

Calibration is how you check and fix this drift. During calibration, you use a certified weight to test the scale. If the reading is off, you adjust the scale to make it correct again. A quality old scale that passes calibration is still a very accurate and reliable tool. The problem is when a scale can no longer be adjusted correctly. That’s when you know its internal parts are too worn out.

Why do bathroom scales stop working?

Is it frustrating that your bathroom scale suddenly died? It's a common problem when you're trying to track your health. I’ll explain the simple reasons why this happens.

Bathroom scales often stop working due to dead batteries, dust interfering with sensors, or moisture damage. More serious failures can involve a damaged load cell from being dropped or overloaded.

Bathroom scales are commercial scales. They are not built for the same durability8 as industrial equipment. Because of this, they are more likely to fail from simple causes. Knowing these can help you troubleshoot the problem.

Common Failure Points

The number one reason a bathroom scale stops working is the batteries. Always check them first. The second big issue is the environment. Bathrooms are wet and humid. Moisture can get inside and damage the electronic parts over time. This is a key difference from our industrial scales, which are sealed to keep water out. Third, the sensors, or load cells, in a bathroom scale are delicate. There is usually one under each foot of the scale. If you drop the scale or store it on its side, you can damage these sensors easily. This can cause the scale to stop working or give very wrong readings. Sometimes, the scale's simple software can also have a problem. Taking the batteries out for a minute can reset it and sometimes fixes the issue.

Conclusion

A scale's lifespan depends on its type, build quality, and care. Industrial scales are a long-term investment. They provide accuracy and durability that commercial scales simply cannot match.

-

Learn about the key differences between commercial and industrial scales to choose the right one for your needs. ↩

-

Explore the advantages of industrial scales for heavy-duty applications and their long-term reliability. ↩

-

Learn about the significance of IP67 ratings and how they protect scales from environmental factors. ↩

-

Discover the technology behind load cells and their importance in ensuring accurate measurements. ↩

-

Explore tips and techniques to maintain the accuracy of your digital scales over time. ↩

-

Discover the benefits of integrating scales with software systems for improved data management. ↩

-

Understanding the lifespan of digital scales can help you make informed purchasing decisions. ↩

-

Find out the key factors that contribute to the durability of industrial scales. ↩

Comments (0)