Worried about fines from overweight trucks? The rules are complex and constantly changing. Knowing how often drivers must weigh saves money and ensures compliance.

A long-distance truck driver’s use of weigh scales depends on regulations and the type of cargo. It can range from every highway entry and daily checks at loading sites to random inspections on the road. The frequency is not fixed but event-driven.

The "how often" question isn’t simple. It’s not just about stopping at weigh stations. The real answer involves different types of scales, specific regulations, and even the cargo1 itself. It’s a critical part of a driver’s daily life, impacting their schedule, route, and safety. Let’s look closer at the details you need to know to understand the full picture.

How frequently are long-distance truck drivers required to stop at weigh stations?

Do your drivers feel like they’re always stopping at weigh stations? This can disrupt schedules and add stress. Knowing the real requirements helps plan better routes and reduce delays.

In general, truck drivers must stop at all open weigh stations along their route. However, modern bypass programs and weigh-in-motion (WIM) technology now allow compliant trucks to skip these stops, improving efficiency while still ensuring road safety.

The experience of stopping at weigh stations has changed over the years. What was once a mandatory stop for every truck is now becoming a more intelligent process. As a scale manufacturer, we are at the forefront of this evolution, providing the hardware that powers these smarter systems.

Mandatory Stops vs. Bypass Programs

Traditionally, all commercial trucks are required to pull into any open weigh station they pass. This is a legal requirement in every state. These stops allow officials to check the truck’s weight, the driver’s logbook, and the vehicle’s safety credentials. However, these stops create bottlenecks and cost drivers valuable time.

The Rise of Smart Weighing

This is where technology comes in. Modern bypass services use transponders in the truck and sensors at the weigh station to screen vehicles as they approach. If the truck’s credentials and weight history are in good standing, the driver gets a signal to bypass the station. Our IoT-enabled scales2 can integrate seamlessly with these systems. For software vendors, this integration is a massive opportunity. You can develop platforms that use our real-time, accurate weight data to help fleets improve their safety scores and qualify for more bypasses, saving them time and money.

What are the regulations for truck drivers regarding weigh scale usage during interstate travel?

Interstate rules for truck weighing are confusing and vary by state. Breaking a rule in one state can cause huge delays and fines for drivers. Understanding the core regulations is crucial.

The primary regulation comes from the Federal Highway Administration (FHWA), which sets gross vehicle weight limits. However, each state enforces these rules and can add its own specific laws, like bridge formulas or periodic inspections, making compliance a complex task.

Navigating the web of federal and state laws is a major challenge for the trucking industry. For over 18 years, we have been manufacturing weighing systems designed to meet these varied and strict requirements. This experience gives us a unique perspective on a problem that our software partners are trying to solve.

Federal Foundation and State Specifications

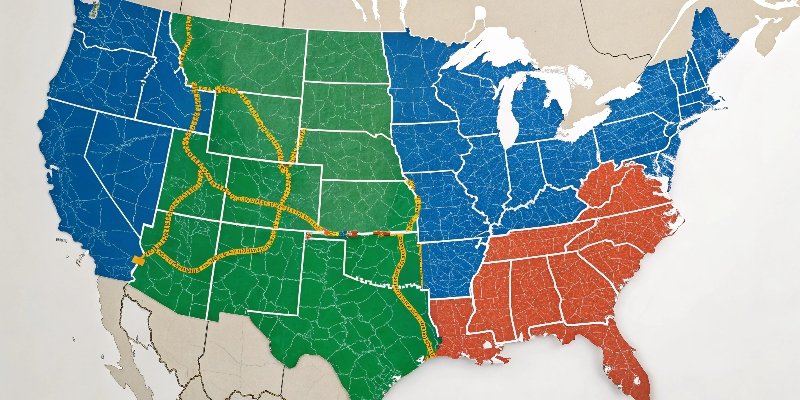

The federal government sets the baseline. For travel on the interstate highway system, the maximum gross vehicle weight is typically 80,000 pounds. However, states manage their own roads and can have different limits. States are also responsible for enforcement. We see this in our work globally. For instance, we helped a client in China implement scales compliant with the GB1589-2016 standard, which strictly controls weight at every highway entrance.

Unique Regional Demands

Some states have very specific rules. I remember a project for a client in Oregon where they needed scales certified for a state program requiring vehicle weigh-ins every six months. This highlights how critical it is to have equipment that is not only accurate but also certified for specific regional regulations. For software providers, this means your solutions must be flexible. They need a solid hardware foundation that works anywhere. Our products come with international certifications like CE, ensuring they provide that reliable, compliant base for your software systems.

Why do long-haul truck drivers need to use weigh scales, and how does it impact their routes?

Weighing seems like just another delay in a driver’s tight schedule. But skipping it risks huge fines and serious dangers. Understanding the "why" helps everyone see weighing as a vital safety check.

Drivers use weigh scales primarily for safety and legal compliance. An overweight truck can damage roads, cause brake failure, and become a major safety hazard. This means drivers must plan routes that include weigh stations or facilities with certified scales for loading.

The need to weigh a truck is not a single event but a process that happens at different stages of a journey. As a weighing expert, I see this as more than just a rule; it’s a core part of logistics management3. We’ve developed a range of products to fit each specific need.

The Three Main Weighing Scenarios

Weighing happens for different reasons and in different places. This is a key insight for any software company looking to serve the logistics industry. Your software can become much more powerful if it can connect the data from these different weighing events. This creates a complete picture of the vehicle’s load throughout its journey.

| Scenario Type | Frequency of Use | Common Scale Type | How It Impacts Routes |

|---|---|---|---|

| Regulatory Weighing | Every time at highway entrances or periodic checks | Fixed weigh stations, Weigh-In-Motion (WIM) | Routes must be planned to pass open weigh stations. |

| Operational Weighing | 1-2 times daily per job (loading and unloading) | Truck scales, floor scales | Routes must start and end at facilities with scales. |

| On-Demand Self-Checks | As needed, especially for oversized or bulk loads | Portable axle weigh pads | Allows more route flexibility by enabling proactive checks anywhere. |

Are there penalties for truck drivers who bypass required weigh stations?

Thinking of skipping a weigh station to save time? This gamble can lead to severe penalties. The consequences are far worse than the few minutes saved on the road.

Yes, the penalties for bypassing a required weigh station are serious. They can include heavy fines, points on a driver’s commercial license, and a full, time-consuming vehicle inspection. Repeat offenses can even risk the trucking company’s authority to operate.

No responsible fleet manager or driver ever wants to face these penalties. It’s not just about the money; it’s about reputation, safety, and operational integrity. At Weigherps, we believe that good technology is the best way to prevent these issues before they happen.

The True Cost of Bypassing

The fines for illegally bypassing a weigh station can range from a few hundred to several thousand dollars. But the immediate financial hit is often just the beginning. If caught, a driver will almost certainly be pulled over for a comprehensive, Level 1 inspection. This can take hours, completely destroying a delivery schedule and causing major disruptions for the customer. It also negatively impacts the carrier’s safety score, which can lead to higher insurance rates.

How Technology Provides a Solution

This is where smart weighing systems become essential. Our IoT-enabled scales can provide real-time weight data directly to the driver’s cab and the fleet manager’s dashboard. When your software is connected to our reliable hardware, you can build powerful tools. Imagine a system that alerts a driver when they are approaching their legal weight limit during loading. This proactive approach helps prevent accidental overloads and ensures compliance from the start. It transforms weighing from a risk into a tool for efficiency and safety.

Conclusion

In short, drivers use weigh scales frequently for legal, safety, and operational reasons. Integrating reliable weighing technology into your fleet management is key to staying compliant and efficient on the road.

Comments (0)