Are you worried about your digital scale failing at a critical moment? This can disrupt your workflow and lead to costly errors. Understanding your scale’s battery needs is the key.

The frequency depends on battery type and usage. For light use, CR2032 coin batteries last 1-2 years. For heavier use with AA batteries, check every 3-6 months. Rechargeable lithium batteries can last for several years with proper charging cycles before needing replacement.

As a manufacturer of industrial scales1 for 18 years, I’ve seen how a simple component like a battery can make or break an operation’s efficiency. It’s a small detail that has a huge impact on your daily work, your data accuracy2, and your bottom line. I’ve worked with countless clients, from wholesalers to software providers, who need their hardware to be absolutely reliable. Their software and systems depend on the data our scales provide. So, let’s dig a little deeper into this topic. We want you to feel confident in your equipment.

How do you know when your scale needs new batteries?

You rely on your scale for accurate data, but what if a failing battery is silently causing problems? This uncertainty can lead to wasted time troubleshooting and potential inaccuracies in your work.

Your scale will give you clear signs. Look for a dim or flickering display, slow response times when weighing, error messages, or a specific low-battery icon. Any of these indicators means it’s time to change the batteries to ensure continued accuracy.

In my experience, scales give both obvious and subtle clues. The obvious ones, like a blinking light or an icon, are easy to spot. But the subtle signs are often more dangerous because they can go unnoticed. A scale that is slow to stabilize or shows fluctuating readings might be written off as a calibration issue3, but very often, it’s just a weak battery struggling to provide consistent power to the sensitive electronics.

For our clients in the software and IoT space, this is critical. Their systems rely on fast, accurate data. We design our modern IoT scales to push notifications directly to a user’s dashboard or management software when the battery level drops below a certain threshold. This removes the guesswork completely. It’s a feature our tech-focused partners really value because it ensures the hardware foundation of their system is always stable.

| Indicator Type | Description | What to Look For |

|---|---|---|

| Visual | Direct clues on the scale’s display. | LOW, Lo, a battery icon, dim or flickering screen. |

| Functional | Performance issues during operation. | Slow to show weight, weight drifts up or down, shuts off unexpectedly. |

| Advanced | Software-based alerts (on connected scales). | Email/SMS alerts, dashboard warnings, API status flags. |

How long do digital scale batteries last?

Planning for maintenance is hard when you don’t know when a device might fail. Unplanned downtime to change batteries across multiple scales is inefficient and disrupts operations. Knowing the expected lifespan helps you schedule ahead.

Battery life varies by type. Small CR2032 coin cells last 1-2 years. Common AA alkaline batteries last 3-5 years but need checks every few months with high use. Rechargeable lithium batteries can handle over 500 charge cycles, lasting for years.

The battery type4 is the biggest factor, but it’s not the only one. The environment plays a huge role. A scale used in a cold warehouse will drain its batteries faster than one in a climate-controlled office. Features like a backlit display or constant connectivity to a network also consume more power.

At Weigherps, we focus on power efficiency in our designs. We know our industrial clients can’t be changing batteries all the time. Our scales use low-power components and have smart features like an auto-off timer that turns the scale off after a period of inactivity. For our IoT-enabled models, we’ve optimized the data transmission process to use the least amount of energy possible. This extends the time between charges or battery swaps, which is a major benefit for busy facilities. When a purchasing manager asks me about an operating budget, battery life is always part of the conversation.

| Battery Type | Typical Lifespan | Best For | Key Considerations |

|---|---|---|---|

| CR2032 Coin Cell | 1-2 years | Low-power, infrequent use (e.g., small kitchen scales). | Not suitable for heavy industrial use. |

| AA/AAA Alkaline | 3-5 years | General purpose, moderate to high use. | Check power levels if used daily. Prone to leakage if left in for too long. |

| Rechargeable Lithium | 500+ charge cycles (several years) | High-use industrial and IoT scales. | Higher upfront cost, but lower total cost of ownership. |

Do digital scales lose accuracy when the battery is low?

You trust your scale to provide correct measurements for everything from shipping to formulation. But what if a low battery is making those readings unreliable, creating hidden costs and quality control issues?

Yes, a digital scale can absolutely lose accuracy when the battery is low. The internal load cell and processor require a stable, consistent voltage to function correctly. When voltage drops, the measurements can become erratic, unstable, or simply incorrect.

I remember a client in the logistics industry who was facing chargebacks for incorrect shipping weights. We discovered their dispatch scales’ batteries were running low. The scales weren’t dead, but they were giving readings that were off by a small but significant margin. This simple issue was costing them thousands. The scale’s brain, the analog-to-digital converter (ADC), needs a precise reference voltage to turn the physical weight into a digital number. If that voltage is weak, the calculation is wrong.

This is why quality matters so much. At our company, every scale undergoes rigorous testing before it leaves the factory. Part of that testing involves checking the low-voltage behavior. Our professional scales are designed with safeguards. They will either display a clear error message and stop weighing, or shut down completely before they start giving inaccurate readings. This is a non-negotiable feature for any professional application. It protects your data integrity, which is essential for the software vendors and system integrators we partner with.

What is the lifespan of a digital weighing scale?

You’re buying more than just a tool; you’re making an investment. You don’t want to find yourself needing to replace a critical piece of equipment every few years due to unexpected failure.

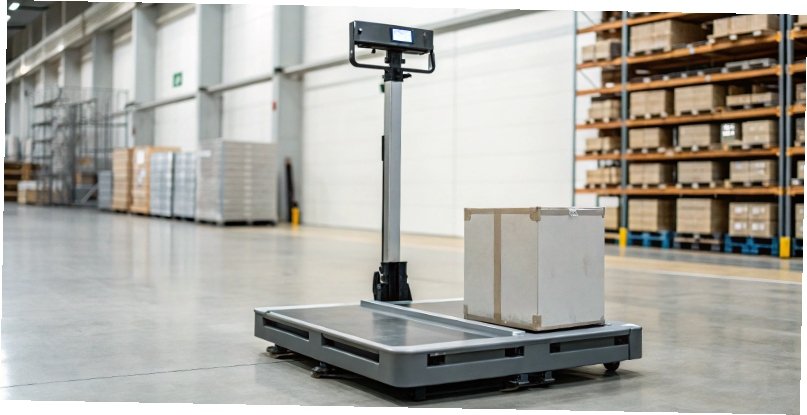

A high-quality industrial digital scale should last 5 to 15 years, or even longer. Its lifespan depends more on build quality, the operating environment, and regular maintenance than on its batteries or basic electronics. A cheap scale might last only 1-2 years.

While batteries are a consumable part you replace, the scale itself is an asset. Its longevity comes down to how well it’s built and how it’s treated. The most important component is the load cell5—the sensor that actually measures the weight. A well-protected, high-quality load cell is the heart of a durable scale. The second factor is the housing and platform. Is it made of cheap plastic or durable stainless steel? Is it sealed against dust and moisture (look for an IP rating6)?

I always tell my customers to think about the total cost of ownership, not just the purchase price. A cheaper scale might save you money today, but it will cost you more in the long run through downtime and frequent replacements. As an OEM/ODM provider, we build scales to meet specific market needs. Some clients need a rugged, waterproof scale for a food processing plant. Others need a highly precise instrument for a lab. The right design and materials ensure the scale lives a long, productive life. Regular calibration and cleaning are the final pieces of the puzzle for a long lifespan.

Conclusion

Managing your scale’s batteries and choosing durable equipment is key. This simple focus ensures your scale provides accurate, reliable data, protecting your operations and maximizing the return on your investment.

-

Discover what to look for in industrial scales to ensure reliability and performance. ↩

-

This resource provides tips to maintain data integrity and avoid costly mistakes. ↩

-

Explore this link to differentiate between calibration issues and battery problems. ↩

-

Understanding battery types can help you choose the right one for your scale, ensuring reliability and longevity. ↩

-

Learn about the critical role of load cells in ensuring accurate measurements in scales. ↩

-

Learn about IP ratings to ensure your scale is protected against dust and moisture. ↩

Comments (0)