Using scales in hazardous areas is risky. A standard device could cause a disaster. You need a specialized explosion-proof scale to ensure safety and compliance in these environments.

Yes, explosion-proof scales are designed specifically for flammable or hazardous environments. They use special components like explosion-proof load cells and enclosures to prevent sparks or contain an explosion. These scales are certified under standards like ATEX and IECEx to guarantee they are safe for use.

In my 18 years of manufacturing industrial scales, safety has always been the top priority for clients in chemical, gas, and manufacturing industries. A simple mistake can have devastating consequences. That is why specialized scales are not just an option; they are a necessity. These devices undergo rigorous testing and certification to prove they can operate safely where flammable dust or gases are present. However, understanding what makes them safe and how to choose the right one is critical. Let's break down the key information you need to make a safe and informed decision for your facility.

What makes a weighing balance safe for use in hazardous areas?

Confused by the term "explosion-proof"? Choosing the wrong scale can be a costly mistake and a huge safety risk. The key is understanding its core protective features.

A balance is safe for hazardous areas because of its design. It uses intrinsically safe circuits that limit energy to prevent sparks. It also has explosion-proof enclosures that contain an internal explosion without igniting the surrounding atmosphere. These features are certified for safety.

At Weigherps, our R&D and production teams focus on two main safety principles1 when engineering these products. The first is intrinsic safety, which involves designing the entire system to be inherently safe. The second method is using robust explosion-proof enclosures2. Both are effective, but they work in very different ways.

Key Safety Designs

Intrinsic safety (IS) is a preventive approach. The electronic circuits inside the scale are designed to operate on such a low level of electrical energy that they are physically incapable of producing a spark hot enough to ignite a flammable substance. This is true even if a wire is cut or a component fails.

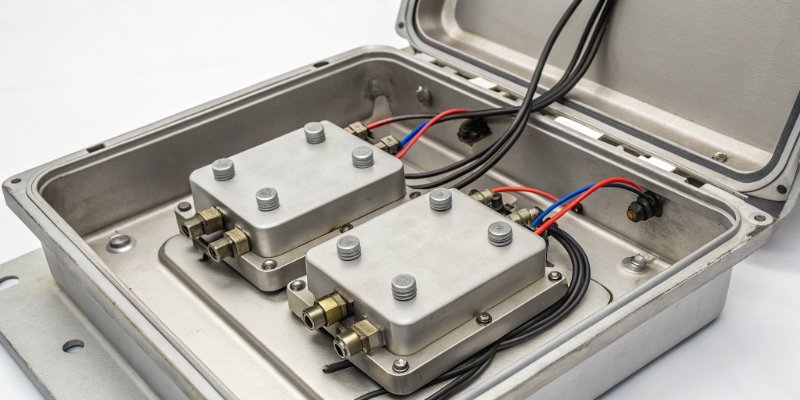

Explosion-proof (or flameproof) enclosures are a containment approach. The scale’s electronics might operate at normal energy levels, but they are housed in a heavy-duty, sealed enclosure. If an internal spark were to cause a small explosion inside the housing, the enclosure is strong enough to contain it completely. It also cools any escaping gases so they cannot ignite the hazardous atmosphere outside.

Here is a simple comparison:

| Feature | Intrinsically Safe (IS) | Explosion-Proof (XP) |

|---|---|---|

| Principle | Prevents ignition | Contains an explosion |

| Energy Level | Very low, non-incendive | Normal energy levels inside |

| Maintenance | Can often be done live | Power must be shut off |

| Cost | Often lower wiring cost | Higher enclosure & installation cost |

Choosing the right design depends on your specific zone requirements and operational needs.

How do I choose the correct explosion-proof scale for a specific hazardous zone?

Not all hazardous areas are equal. Using a scale rated for the wrong zone is a serious compliance breach and a major safety hazard. The key is matching the scale's certification to your specific zone.

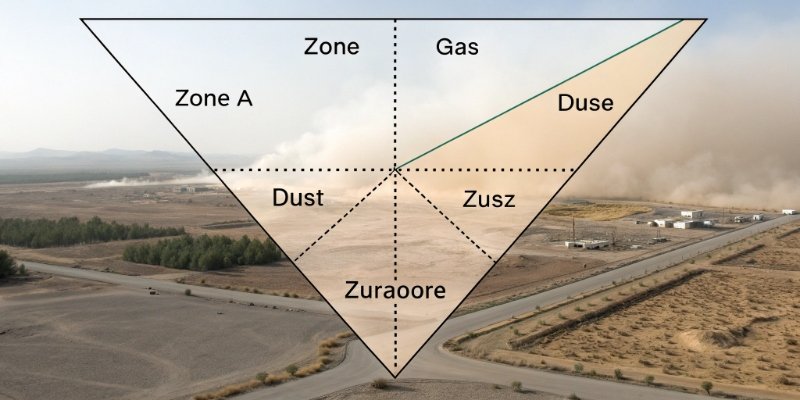

First, you must identify your hazardous zone classification (e.g., Zone 0, 1, or 2 for gas; Zone 20, 21, or 22 for dust). Then, select a scale with a certification that explicitly approves it for that specific zone. Always check the equipment's markings and documentation.

Choosing the right scale always begins with a clear understanding of your work environment. Governments and safety bodies classify hazardous areas into "Zones" based on the frequency and duration that an explosive atmosphere is present. Getting this classification correct is the most important step in the entire selection process. As a manufacturer providing customized solutions, this is always the first question we ask our clients. Providing a scale for Zone 2 to a client in a Zone 1 area would be a dangerous failure.

Understanding Zone Classifications

The zone system helps you match the equipment's safety level to the area's risk level. The higher the risk, the more stringent the equipment requirements are. A scale certified only for Zone 2 cannot be used in a Zone 1 area. Here’s a simple guide to help you understand the classifications:

| Atmosphere | Continuous or Frequent Hazard | Occasional Hazard (Normal Operation) | Infrequent / Short-term Hazard |

|---|---|---|---|

| Gas/Vapor | Zone 0 | Zone 1 | Zone 2 |

| Dust | Zone 20 | Zone 21 | Zone 22 |

For example, Zone 1 is an area where a flammable gas atmosphere is likely to occur during normal operation. A scale used here must be certified for at least Zone 1. Our team guides clients through this analysis to ensure they get a solution that is both fully compliant and cost-effective.

What do ATEX, IECEx, and NEC certifications mean for industrial scales?

Seeing labels like ATEX, IECEx, or NEC can be confusing. Ignoring them means you might buy a scale that isn't legal for use in your region, creating a huge liability. Let's quickly decode these important safety certifications.

ATEX is the European Union's mandatory standard. IECEx is an international certification scheme that simplifies global trade. NEC (National Electrical Code) provides the standards used in the United States. A certified scale has been independently tested and proven to meet these requirements.

These certifications are your guarantee that a product is safe for its intended use. They mean the scale, its sensors, and its software have passed rigorous third-party testing. As a global supplier, we ensure our products meet the required international certifications, like CE, which is directly linked to ATEX compliance. This is a non-negotiable part of our quality assurance process, checked by our quality control department before any product ships.

Global Safety Standards Explained

Each standard or directive serves a specific region or purpose. Understanding the basics helps you confirm that the equipment you are purchasing is compliant in your market. It is a critical detail for any purchasing manager or technical director. Here is a simplified breakdown:

| Certification | Region | Type | Key Point |

|---|---|---|---|

| ATEX | European Union (EU) | Legal Directive | Mandatory for any equipment sold for use in hazardous areas in the EU. |

| IECEx | International | Standard | An international system to facilitate trade. It is often used as the basis for national certifications. |

| NEC | United States | Code | Defines hazardous locations by Class/Division. Enforced by local inspectors. |

When our R&D team develops a product, our engineers consider these standards from day one. This proactive approach ensures the final product is not just functional but also fully compliant for our customers, no matter where they are in the world.

What is the difference between an intrinsically safe and an explosion-proof weighing system?

The terms "intrinsically safe" and "explosion-proof" sound interchangeable. But they refer to very different safety methods. Choosing the wrong one can negatively impact your safety, budget, and maintenance costs.

Intrinsically safe (IS) systems prevent explosions by limiting electrical energy to non-ignitable levels. Explosion-proof (XP) systems contain any potential internal explosion within a robust housing. In simple terms, IS prevents the spark, while XP contains the fire.

We covered the basic principles earlier, but let's examine what this means for your technical team and your budget. As weighing experts, our vision is to help you find the most reliable and professional solution. The choice between Intrinsically Safe (IS) and Explosion-Proof (XP) directly impacts your maintenance procedures3, installation costs, and long-term operational efficiency. We help you find the best balance.

Practical Differences for Your Operation

Your technical director will care about uptime and maintenance. IS systems are a huge advantage here. Because the energy levels are so low, technicians can often perform calibration and service without a full system shutdown or a "hot work" permit. This can save hours of downtime.

Your purchasing manager will focus on total cost. XP systems often require expensive, heavy-duty armored conduit for wiring, which increases installation costs significantly. IS systems can use simpler, less expensive wiring. However, the XP enclosure itself is extremely durable and provides excellent physical protection. The best choice depends on your zone classification4, how often you need to perform hands-on maintenance, and your installation budget. Our team helps you weigh these factors to achieve the most cost-effective solution.

Conclusion

Yes, safe scales exist for hazardous areas. Choose an explosion-proof scale with the right zone certification (like ATEX or IECEx) to ensure safety, compliance, and operational efficiency.

-

Understanding key safety principles helps in selecting the right equipment for safety. ↩

-

Learn how explosion-proof enclosures contain internal explosions and enhance safety. ↩

-

Effective maintenance procedures are essential for safety; learn how to implement them. ↩

-

Understanding zone classification is key to selecting compliant equipment for safety. ↩

Comments (0)