Your operations are stalled by inaccurate scale readings. This costs you time, materials, and money. This guide will help you diagnose and fix the problem quickly.

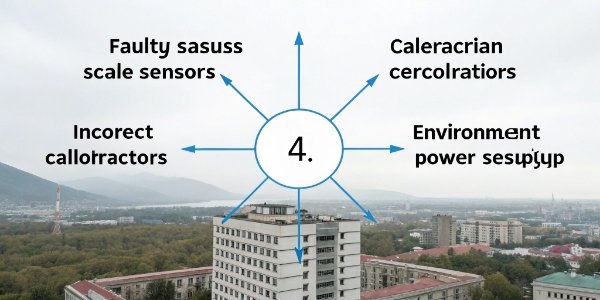

Digital scale inaccuracies usually stem from four main areas: sensor problems, failed calibration, environmental interference, or an unstable power supply. A quick diagnostic check of these key factors will often resolve the issue and restore your scale's precision.

I’ve been manufacturing industrial scales for over 18 years. During that time, I've seen every problem you can imagine. Many clients call us in a panic, but the fix is often simpler than they think. These issues usually fall into a few common categories. Let’s walk through them one by one, so you can solve this yourself.

What are the most common reasons a digital scale becomes inaccurate?

You can't trust the numbers your scale is showing. This uncertainty compromises your product quality and inventory control. Let’s identify the most common culprits behind these errors.

The most common reasons are faulty sensors, incorrect calibration, environmental factors like temperature or vibration, and power supply issues. These four areas are the first places you should check when troubleshooting because they account for the majority of accuracy problems.

Let's break these down further. It's important to approach troubleshooting methodically. Start with the simplest potential causes before looking at more complex hardware issues. Over the years, we've developed a quick-check process that our clients find very helpful.

The Four Main Culprits

- Sensor Faults: The load cell1, or sensor, is the heart of your scale. If it's damaged or disconnected, you'll get wild readings or no reading at all. This can be caused by physical impact, overloading, or corrosion.

- Calibration Errors: A scale's accuracy can drift over time. Regular calibration is necessary to reset its precision. If calibration is done incorrectly or not at all, the readings will be consistently wrong.

- Environmental Interference: Digital scales are sensitive instruments. Factors like drafts from an air conditioner, vibrations from nearby machinery, or even strong electromagnetic fields can disrupt their delicate mechanisms.

- Power Issues: An unstable power source or a dying battery can cause the electronic components to malfunction, leading to fluctuating numbers or a faded display.

Here is a simple table to guide your initial diagnosis.

| Problem Area | Key Symptoms | Quick Check |

|---|---|---|

| Sensors | Wildly jumping numbers, zero drift | Inspect cables for damage, check for loose connections. |

| Calibration | Consistently high or low readings | Recalibrate with a certified weight. |

| Environment | Readings fluctuate with no load | Check for vibrations, drafts, or nearby electronics. |

| Power | Dim display, scale won't turn on | Check the battery level or power adapter connection. |

By checking these four areas first, you can solve most accuracy problems without needing a technician.

Why does my digital scale give inconsistent or fluctuating readings?

Your scale’s display keeps jumping, making work impossible. You can't get a stable reading to continue production. We can help you find the cause and stabilize it.

Fluctuating readings are often caused by environmental interference like vibrations, air currents, or electromagnetic fields from other equipment. They can also indicate a loose sensor connection or an unstable power source. A thorough check of these areas will usually stabilize your scale's display.

When a scale's numbers won't settle down, it’s frustrating. This is one of the most common complaints we hear. The cause is almost always external interference or a connection issue. Before you assume the sensor is broken, let's look at the environment and the wiring.

Diagnosing the Jumps

Start by creating a stable environment for your scale. Turn off any nearby fans, air conditioners, or large motors. Make sure the scale isn't on a workbench where other machinery is causing vibrations. Sometimes, even a strong radio signal can cause interference.

If the environment is stable, the next step is to check the physical connections.

- Power Down: First, always disconnect the scale from its power source for safety.

- Inspect the Cable: Look at the cable that connects the sensor to the indicator. Check for any cuts, frays, or damage, especially near the connectors.

- Check Terminals: Open the junction box or connector panel. Gently tug on each wire to ensure it is securely fastened in its terminal. A loose wire is a very common cause of jumpy readings2.

If you have a multimeter3, you can perform a quick continuity test on the signal wires to ensure there are no breaks or short circuits. A healthy sensor usually has a specific input and output resistance. For many of our models, it’s around 380Ω for input and 350Ω for output. A significant deviation from these values might mean the sensor needs replacement. But in most cases, just tightening a loose wire will fix the problem.

How do you properly calibrate a digital scale to ensure its accuracy?

You need to calibrate your scale but you're not sure how. An incorrect calibration can be worse than no calibration at all. Let's walk through the right steps.

To calibrate properly, first warm up the scale for 30 minutes on a level surface. Use certified standard weights, like OIML-class weights. Follow the manufacturer's instructions precisely to enter calibration mode, place the weight, and save the setting. Always document your calibration results.

Calibration is not just a suggestion; it's a requirement for maintaining accuracy. Think of it as tuning an instrument. Over time, all scales drift. We recommend our clients calibrate their scales every 3 to 6 months, or more often if they are used heavily. A proper calibration procedure is straightforward but requires attention to detail.

The Calibration Checklist

Don't just jump into the calibration menu. Following these steps ensures a successful and accurate calibration every time. Small things, like ensuring the scale is warm, make a big difference. One time, a client called me saying his scale failed calibration repeatedly. It turned out he was calibrating it right after turning it on in a cold warehouse. Letting it warm up solved everything.

| Step | Action | Why It's Important |

|---|---|---|

| 1. Preparation | Clean the scale pan. Turn the scale on and let it warm up for at least 30 minutes. | Ensures electronics are stable and removes debris that could affect weight. |

| 2. Leveling | Place the scale on a firm, level surface away from vibrations. Check the level bubble if your scale has one. | An unlevel scale will not distribute weight evenly across the sensors, causing errors. |

| 3. Use Standard Weights | Use weights that are certified and of a known class (e.g., OIML M1). | Your scale is only as accurate as the standard you use to calibrate it. |

| 4. Follow Instructions | Enter the calibration mode4 according to your scale's user manual. Follow the on-screen prompts exactly. | Each model can have a slightly different procedure. |

| 5. Record Keeping | After a successful calibration, record the date, the weights used, and who performed it. Keep a calibration log5. | Provides a maintenance history and is often required for quality control audits. |

If calibration fails, check if something is touching or blocking the scale pan from underneath. Ensure the surface is perfectly flat and not sinking.

Can a low battery or an uneven surface affect a digital scale's measurements?

Your scale is acting up, but the hardware seems fine. You might be overlooking simple but critical factors. Let’s check the basics: power and placement for a quick fix.

Absolutely. An uneven surface causes inconsistent force on the load cells, which directly leads to measurement errors. A low battery provides unstable power to the electronics, resulting in fluctuating readings, a dim display, or total failure. Both are common and easily fixed problems.

Yes, and these are two of the most frequently overlooked causes of inaccuracy. We often get calls for expensive repairs when all the client needed was a new battery or to move the scale to a flatter table. Before you suspect a major failure, always perform these simple checks.

The Importance of a Solid Foundation

An industrial scale relies on its load cells to measure force precisely. If the scale is not level, the weight is not distributed evenly among the sensors. This will lead to inconsistent readings, especially if the object is placed on different parts of the pan. Most industrial scales come with adjustable feet and a level bubble indicator for this exact reason. Always make sure the bubble is centered before use.

Consistent Power for Consistent Results

The electronic brain of your scale needs a steady, reliable power source to function correctly. A low or dying battery can't provide this. The voltage will fluctuate, causing the processor to make errors. This shows up as a jumping display, a failure to return to zero, or random shutdowns. It’s an easy fix. If your scale is battery-operated, replace the batteries. If it uses a power adapter, ensure it's securely plugged in and the cord isn't damaged.

To prevent these issues, we recommend a simple maintenance schedule.

| Frequency | Maintenance Task | Purpose |

|---|---|---|

| Daily | Check display clarity and keyboard responsiveness. | Catches early signs of electronic or power issues. |

| Weekly | Check battery level or power supply stability. | Prevents unexpected shutdowns and measurement errors due to low power. |

| Monthly | Clean the scale body and check that sensor screws are tight. | Prevents buildup from interfering with mechanics and ensures stability. |

Conclusion

Troubleshooting scale inaccuracies is usually straightforward. Always check your sensors, calibration, environment, and power first. Regular maintenance is the key to ensuring your equipment remains accurate and reliable for years.

-

Understanding load cells is key to diagnosing scale issues effectively. ↩

-

Discover the common culprits behind unstable readings and how to fix them. ↩

-

Learn how to use a multimeter for troubleshooting scale issues effectively. ↩

-

Learn the steps to access calibration mode for accurate scale adjustments. ↩

-

Keeping a calibration log is essential for quality control and audits. ↩

Comments (0)