Your industrial scale is giving you inaccurate readings, and you're worried about expensive repairs. But before you panic, the problem might be something you can fix in minutes.

Most scale errors are not due to broken hardware. They are often caused by simple binding issues, like dirt or debris blocking the sensor. A quick cleaning and inspection can often resolve the problem and save you the cost of a service call or replacement.

Before you pick up the phone to call a technician, I want you to take a deep breath. Over my 18 years in this industry, I've seen countless frantic calls about "broken" scales. More often than not, the issue wasn't a catastrophic failure. It was something much simpler. Let's walk through how you can diagnose the problem yourself. This quick process could save you a significant amount of time and money, and it's easier than you think.

How do you know if your scale is broken?

You're getting inconsistent weights, and it's slowing down your entire operation. It's frustrating when you can't trust your equipment. Here’s how you can quickly diagnose the issue.

Look for specific symptoms. A simple binding problem often causes the weight to drift slightly or take a long time to settle. Serious hardware damage usually results in a fixed error code, large and sudden jumps in weight, or visible physical damage to the scale.

When a scale starts acting up, the first step is to observe its behavior closely. Don't just assume it's broken. You need to become a detective for a moment. One of my clients was about to order a new $2,000 scale, but a five-minute inspection revealed a small zip tie fragment had fallen into the mechanism. Removing it fixed the problem completely.

To help you figure this out, look at three key areas: the display, the weighing behavior1, and the physical condition of the sensor. A binding issue and true hardware damage show very different signs.

Here is a simple table to help you tell the difference:

| Category | Signs of a Simple Binding Issue | Signs of Real Hardware Damage |

|---|---|---|

| Display Anomaly | The weight drifts slightly when empty (e.g., ±0.3kg). | It shows a fixed error code2 (like ERR-03). |

| Weighing Action | The numbers settle very slowly (over 5 seconds). | The weight jumps wildly by more than ±0.5kg. |

| Physical Check | You can see dust or fibers around the sensor. | The sensor has dents, scratches, or signs of rust. |

Why did my scale break?

A sudden scale failure can interrupt your workflow and cause major headaches. You wonder what happened. The cause is often simpler and more preventable than you might think.

Most scale "failures" are not breaks, but blockages. Dust, debris, or stray fibers get caught in the sensor mechanism, causing it to "bind." True breaks come from physical impacts, being overloaded, or simple hardware aging after years of constant use.

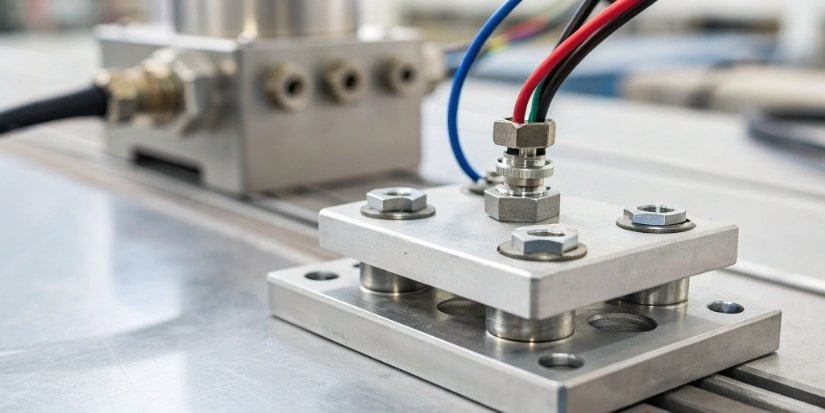

In busy industrial environments, it's easy for things to get a little dirty. And for a precision instrument like a scale, a little dirt can cause a big problem. The most common "break" we see isn't a break at all. It's an obstruction. The load cell3, which is the sensor that measures weight, needs to move freely. When something gets stuck in the small gaps around it, it can't measure accurately. This is what we call a binding issue.

Other causes are more serious. For example, dropping a heavy object on the scale or consistently overloading it past its capacity can permanently damage the load cell. It's like bending a metal ruler—it won't go back to its original shape. Lastly, every electronic component has a lifespan. After years of use, the sensors and internal circuits can simply wear out and start to lose their accuracy. This is a gradual process, unlike the sudden error caused by a physical impact.

Can a scale be off by 10 pounds?

A 10-pound error isn't just an inconvenience; it's a critical failure. It can ruin your inventory data and quality control. Let's explore why this happens.

Yes, a scale can definitely be off by 10 pounds or even more. An error that large almost always points to a major hardware problem, like a damaged load cell or a failed electronic board. It is very rarely a simple binding or cleaning issue.

If your scale is off by a small, inconsistent amount, it might be a simple fix. But when you see a massive and consistent error, like being off by 10 pounds, you're looking at a more serious problem. This is a red flag that requires immediate attention. A binding issue from dust might throw the reading off by a few ounces or tenths of a kilogram, not multiple pounds.

A large error usually comes from one of three places. First, the load cell could be physically damaged from a severe impact or extreme overload. Second, the scale's internal calibration4 could be completely corrupted, maybe after a power surge or a failed update. Third, a critical electronic component on the mainboard could have failed. A good way to check this is with a multimeter. At our facility, our technicians test the resistance of the load cell's circuits. If the measured resistance is more than 5% different from the manufacturer's specification, there's a very high chance the sensor is fried and needs to be replaced.

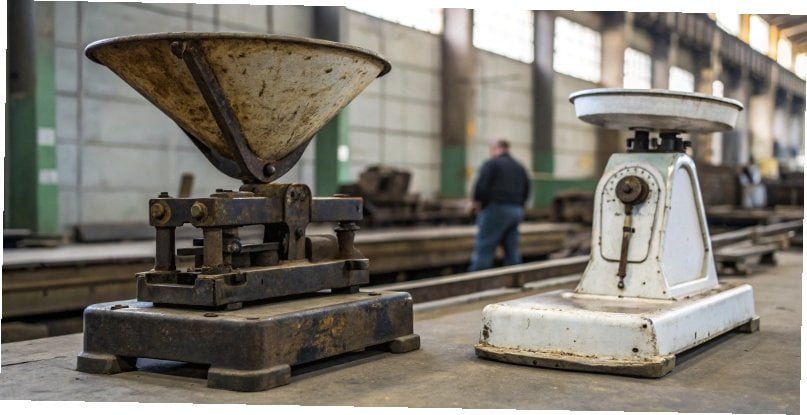

What is the lifespan of a digital scale?

Every piece of equipment wears out eventually. Knowing your scale's expected lifespan helps you budget and plan for replacement, avoiding unexpected downtime. So, how long should one last?

A well-made industrial digital scale typically has a lifespan of 5 to 8 years. This lifespan is directly affected by how heavily it's used, the cleanliness of its operating environment, and whether it receives regular maintenance and calibration.

Like any tool, a scale's longevity depends on how you treat it. A scale that weighs 50 or more items a day will naturally wear out faster than one used only a few times a week. The environment also plays a huge role. A scale in a dusty workshop or a damp processing plant will face more challenges than one in a clean, climate-controlled lab.

This brings us to the question of repair versus replacement. My advice is to consider both the age and the cost. If your scale is having a simple binding issue, the solution is easy and cheap. But if a major component fails, you need to weigh the costs.

Repair vs. Replace Cost Guide

| Issue Type | Solution | Estimated Cost (Industrial Grade) |

|---|---|---|

| Binding Issue | Clean sensor & recalibrate (quarterly) | $50 - $100 (includes labor) |

| Sensor Aging | Replace sensor & professional calibration | $200 - $400 (includes parts) |

| Mainboard/Display Damage | Replace component (often factory repair) | $300 - $600 (includes shipping) |

As a general rule, if your scale is over 3 years old and used heavily, and the repair cost is more than half the price of a new one, replacement is often the smarter financial decision.

Conclusion

Don't assume your scale is broken. Always check for simple binding issues first. Regular cleaning and understanding when to repair versus replace will save you significant time and money.

-

Explore factors that influence weighing behavior to ensure accurate measurements. ↩

-

Decoding error codes can help you quickly identify and resolve scale issues. ↩

-

Understanding load cells is crucial for diagnosing scale issues and ensuring accurate weight measurements. ↩

-

Regular calibration is essential for accuracy; find out how often it should be done. ↩

Comments (0)