It's a common problem: a perfectly good load cell, but the label is gone. Without its specifications, you can't use it, leading to project delays and wasted money.

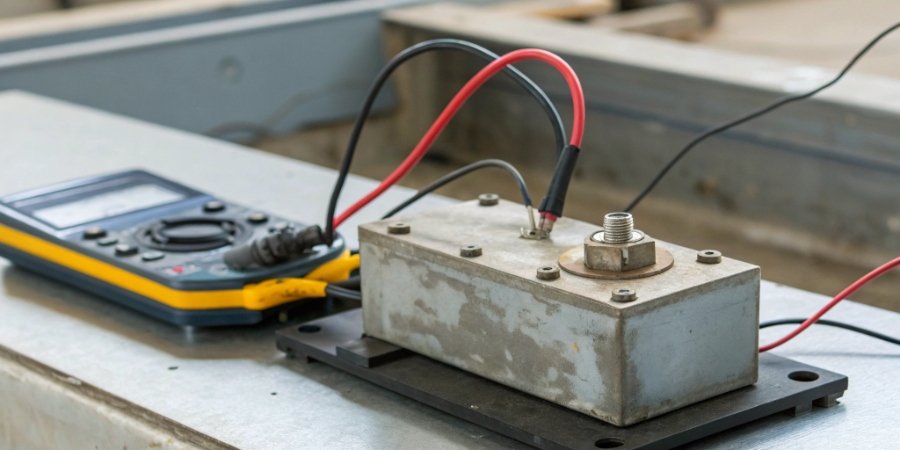

To identify a worn load cell's sensitivity, you need a known weight, a stable power supply, and a precision multimeter. By measuring the voltage output with no load and then with the known weight, you can calculate the sensitivity, typically expressed in millivolts per volt (mV/V).

I've been in this industry for 18 years, and I've seen this happen more times than I can count. A load cell1 gets moved around the workshop, cleaned with the wrong solvent, or just lives a long, hard life, and the label that holds all its secrets peels away. Your first instinct might be to toss it in the parts bin, but don't be so quick. That could be a perfectly functional and valuable piece of equipment.

Getting that key piece of information, the sensitivity2, is entirely possible. But it’s not just about finding one number. To be truly confident in the load cell, you also need to know if it's working correctly and if it's still accurate. So, let’s start with the first step. How do you actually calculate the sensitivity?

How to calculate sensitivity of load cell?

You have the raw voltage numbers from your multimeter, but you're not sure how to turn them into a usable sensitivity value. Using the wrong formula can cause major calibration errors.

Calculate sensitivity by first recording the output voltage with no load. Then, apply a known weight and record the new voltage. The difference in voltage, divided by the excitation voltage you supplied, gives you the sensitivity in millivolts per volt (mV/V).

To get this right, you need to be methodical. It's a simple process, but every step matters for an accurate result. As someone who oversees production, I know that precision starts with having the right tools and a clear procedure. Let's break down exactly how I would do it on our testing bench.

Step 1: Gather Your Equipment

First, you need the right tools. Don't eyeball this.

- High-Precision Multimeter: It must be able to accurately measure millivolts (mV). A standard electrician's multimeter might not be sensitive enough.

- Stable DC Power Supply: This provides the excitation voltage. It must be stable, as fluctuations here will directly cause errors in your output signal. We typically use 10V DC.

- Standard Weights: These must be known, calibrated weights. Guessing the weight of an object won't work.

Step 2: Perform the Measurements

With your tools ready, connect the load cell. The power supply connects to the excitation wires (usually red and black), and your multimeter connects to the signal wires (usually green and white).

- With no weight on the load cell, power it on and let it stabilize. Record the voltage reading. This is your "zero-load output3."

- Place your known weight carefully on the load cell. Let the reading stabilize and record this new voltage. This is your "full-load output4."

Step 3: Apply the Formula

The formula for sensitivity is quite simple.

| Variable | Description | Example Value |

|---|---|---|

| V_excitation | The stable voltage you supply. | 10 V |

| V_output_zero | The signal with no load applied. | 0.05 mV |

| V_output_full | The signal with a known weight. | 20.05 mV |

| Sensitivity | The final calculated value. | (20.05 - 0.05) / 10 = 2.0 [mV/V](https://weigherps.com/what-does-mv-v-sensitivity-actually-mean-on-a-load-cell/)[^5] |

Using the example values in the table, the calculation is (20.05 mV - 0.05 mV) / 10 V, which equals 2.0 mV/V. This means your load cell has a sensitivity of 2.0 mV/V, a very common industry standard.

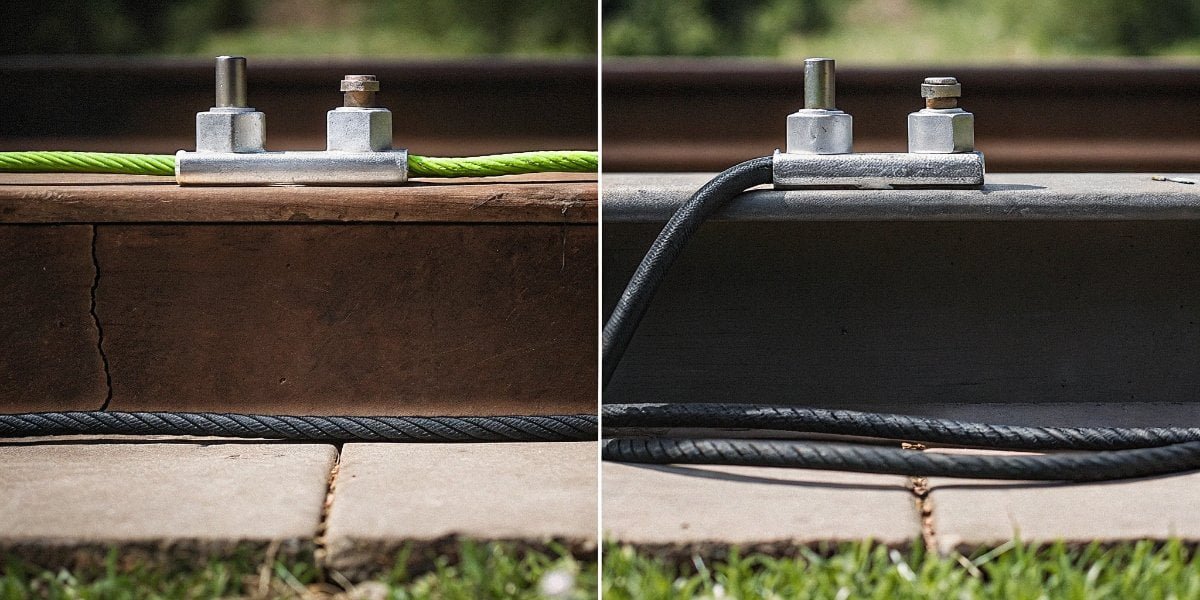

How to check if a load cell is damaged?

You're not sure if the load cell is just unlabeled or if it's actually damaged. Using a faulty load cell could compromise your entire measurement system and lead to costly failures.

Check for damage by first doing a physical inspection for cracks or bends. Then, use a multimeter to measure the input, output, and insulation resistance. Readings that are open, shorted, or unstable compared to standard values indicate internal damage.

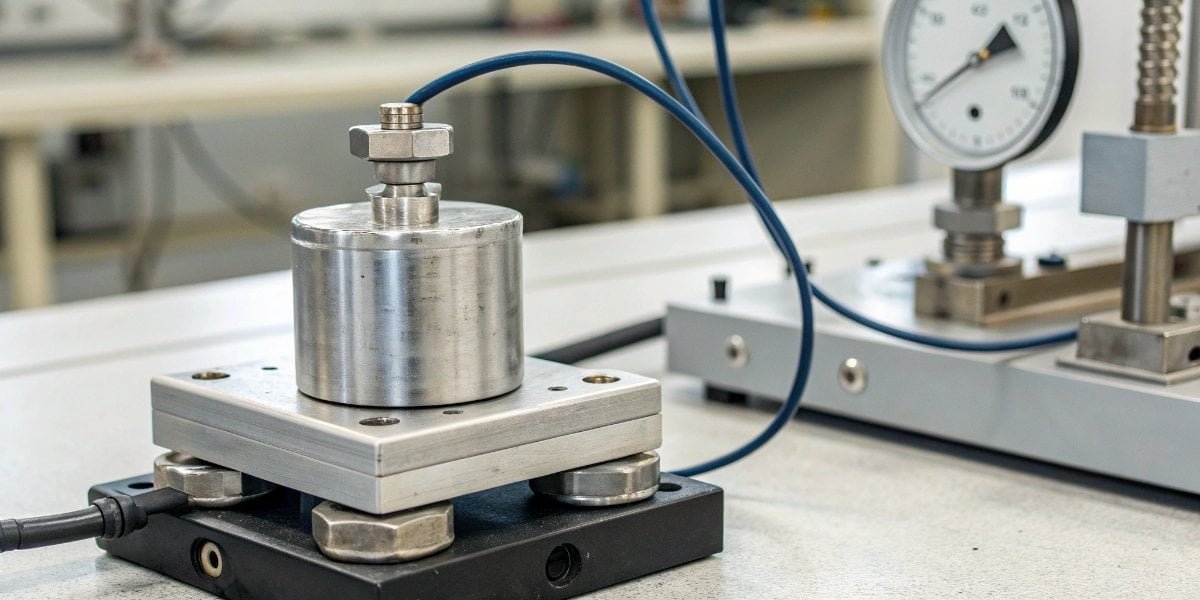

Before you spend time calculating sensitivity, a quick health check is always a good idea. A load cell can be electrically "alive" but mechanically compromised, or vice versa. In our quality control department, every single unit undergoes these checks before it ever leaves our facility. Here’s a simplified version of what our team does.

Physical Inspection

This is the easiest first step. Look closely at the load cell's body. Are there any obvious dents, cracks, or signs of it being bent or overloaded? Check the cable. Is it frayed, cut, or crushed? Also, look for signs of corrosion or water entry, especially around where the cable enters the body. Any significant physical deformity is a red flag, as the precise mechanical structure is what allows it to work.

Electrical Resistance Checks

This is where your multimeter becomes a diagnostic tool. A load cell is based on a Wheatstone bridge5 circuit, and checking the resistance across different wires can tell you a lot about its health.

| Measurement Point | What It Is | Expected Reading | Signs of Damage |

|---|---|---|---|

| Input Resistance | Between Exc+ and Exc- wires. | Typically 350Ω or 700Ω. | A reading of 0 (short) or infinite (open) means it's broken. |

| Output Resistance | Between Sig+ and Sig- wires. | Should be close to the input resistance6. | A reading that is very different points to a damaged gauge. |

| Insulation Resistance | Between any wire and the load cell body. | Should be very high, in the mega-ohms (MΩ). | A low reading suggests moisture got inside, causing a short. |

If all these physical and electrical checks pass, you can have much more confidence that the load cell is healthy. If any of them fail, I would not recommend using it, as its readings will be unreliable.

How to determine load cell accuracy?

You've found the sensitivity, but how do you know if the load cell is still accurate? An inaccurate load cell can pass basic tests but still give you unreliable data, affecting your product quality.

Determine accuracy by testing its linearity and repeatability. Apply known weights in several steps up to its capacity and record the output. The readings should increase in a straight line, and you should get the same reading every time you apply the same weight.

Finding the sensitivity is just one parameter. Accuracy is about how trustworthy that sensitivity value is across the load cell's entire working range. A good load cell is predictable. An inaccurate one is not. The two most important characteristics to check for are linearity7 and repeatability8.

Testing for Linearity

Linearity is a measure of how straight the "output vs. load" line is. A perfect load cell would have a perfectly straight line.

- Start with zero load and record the output.

- Apply a weight that is 25% of the load cell's estimated capacity. Record the output.

- Increase the weight to 50%, 75%, and 100% of capacity, recording the output at each step.

- The increase in voltage should be proportional at each step. For example, the voltage jump from 0% to 25% should be very close to the jump from 25% to 50%. If the output at 50% is not double the output at 25%, you have a linearity problem.

Checking Repeatability

Repeatability is the ability of the load cell to give the same output for the same load, over and over again. It's a measure of consistency.

- Place a known weight (e.g., 50% of capacity) on the load cell and record the output.

- Remove the weight.

- Place the same weight back on the load cell and record the new output.

- Repeat this 5-10 times.

The readings should be nearly identical. If the values are drifting or jumping around, the load cell is not repeatable and cannot be trusted for precise applications. At Weigherps, Our products are carefully designed and customized to meet a variety of market demands., and we guarantee repeatability within very tight tolerances because we know our clients depend on it.

How sensitive are load cells?

You see sensitivity values like "2.0 mV/V," but what does that actually mean for your project? Choosing a load cell with the wrong sensitivity could result in a signal that is too weak or too strong for your electronics.

Most industrial load cells have a standard sensitivity of 2.0 mV/V or 3.0 mV/V. This means for every one volt of power you supply, the load cell outputs 2 or 3 millivolts of signal at its maximum rated capacity.

After 18 years in this business, I've found that demystifying the specifications is one of the best ways I can help my clients. "Sensitivity" sounds complex, but it's a very simple and practical concept once you break it down.

What Does mV/V Mean?

Let's make this simple. The "mV/V" unit stands for millivolts per volt.

- mV (millivolts): This is the output signal from the load cell that your instrument reads.

- V (volt): This is the input power (excitation) you supply to the load cell.

So, a sensitivity of 2.0 mV/V means: "This load cell will produce 2.0 millivolts of output signal for every 1 volt of excitation I provide, when it is loaded to its maximum capacity."

For example, if you have a 100 kg load cell with 2.0 mV/V sensitivity and you power it with 10V:

- At 0 kg, the output is 0 mV (ideally).

- At 100 kg (full capacity), the output signal will be 2.0 mV/V * 10V = 20 mV.

This 20 mV range is what your controller or indicator will use to measure weight.

Common Sensitivity Ratings

The good news for anyone integrating weighing components is that the industry has largely standardized. The vast majority of industrial load cells you will encounter, including the ones we produce, are rated at 2.0 mV/V or 3.0 mV/V. This makes it much easier to design systems and swap out components, as many weighing indicators and transmitters are pre-configured to work with these sensitivities.

How Sensitivity Affects Your Application

So, which one is better? A higher sensitivity, like 3.0 mV/V, provides a larger output signal (30 mV in the example above). This stronger signal is less susceptible to electrical noise9 and can be easier for your electronics to measure accurately, giving you better resolution for small changes in weight. This is why we often recommend higher sensitivity load cells for high-precision batching or dosing applications. However, a 2.0 mV/V load cell is a robust and reliable workhorse, perfectly suitable for thousands of applications from platform scales to tank weighing.

Conclusion

Finding the sensitivity of an unlabeled load cell is possible with the right tools. By checking for damage and verifying its accuracy, you can confidently reuse it in your system.

-

Understanding load cells is crucial for accurate weight measurement in various applications. ↩

-

Learn the importance of sensitivity in load cells to ensure accurate measurements. ↩

-

Knowing zero-load output is essential for calculating load cell sensitivity. ↩

-

Understanding full-load output is key to assessing load cell performance. ↩

-

The Wheatstone bridge is fundamental to understanding load cell operation. ↩

-

Understanding input resistance helps diagnose potential issues in load cells. ↩

-

Testing linearity ensures that load cells provide accurate and consistent readings. ↩

-

Repeatability is crucial for ensuring consistent measurements in load cell applications. ↩

-

Understanding electrical noise is crucial for ensuring accurate load cell readings. ↩

Comments (0)