Struggling with weighing inaccuracies that hurt your bottom line? Choosing the right scale technology is critical for your operational success, but the options can be confusing and overwhelming.

The best scale technology depends on your specific needs. Strain gauge is cost-effective for general use, force motor offers high precision for labs, and SAW is durable for harsh environments. Assess your application, environment, and budget to make the right choice for your business.

This decision seems complex, but it doesn't have to be. As an industrial scale1 manufacturer with over 18 years of experience, I've helped countless businesses navigate this choice. We've built custom solutions for nearly every industry imaginable. Let's break down these technologies together. I want to give you the clarity you need to select a system that not only works but helps your business grow.

Are strain gauges used in scales?

Unsure if such a common technology is reliable enough for your industrial needs? You see strain gauges mentioned everywhere, but you rightly question if they can handle high-stakes weighing.

Yes, strain gauges are one of the most common and reliable technologies used in electronic scales. They are the core component of a load cell, which converts the force from a weight into a measurable electrical signal. They are valued for their reliability and cost-effectiveness.

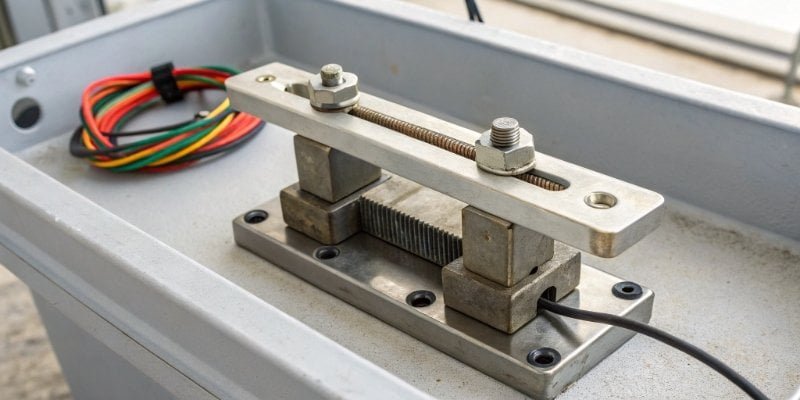

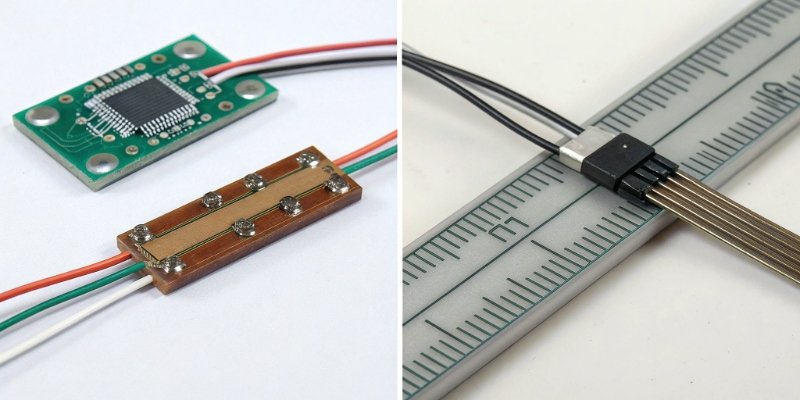

A strain gauge2 is a very simple but clever device. Think of it as a flexible sticker with a special metallic foil pattern on it. We bond this sticker to a structural component inside the scale called a load cell3. When you place a weight on the scale, it causes the load cell to bend or deform just a tiny, microscopic amount. This deformation stretches or compresses the foil on the strain gauge, changing its electrical resistance. Our scale's electronics measure this tiny change in resistance with extreme precision and convert it into the weight reading you see on the screen.

Why It's Popular

The reason strain gauge technology is so widespread is that it hits a perfect balance of performance and cost. It's accurate enough for the vast majority of commercial and industrial applications4, from shipping warehouses to food production lines. I remember a client in the logistics industry who was worried about the durability5 of strain gauge scales for their busy warehouse. We showed them how our industrial-grade load cells are designed to withstand constant use and minor overloads, and they've been using them reliably for years.

| Aspect | Strain Gauge Performance |

|---|---|

| Accuracy | High for most industrial needs |

| Cost | Cost-effective and affordable |

| Durability | Very robust when built into a quality load cell |

| Applications | Retail, logistics, manufacturing, agriculture |

What is the difference between strain gauge and FSR?

Confused by similar-sounding sensor terms like strain gauge and FSR? Choosing between them can be tricky, and an incorrect choice can lead to completely inaccurate and useless measurements for your process.

The key difference is precision and application. Strain gauges provide accurate, linear, and repeatable weight measurements, making them ideal for certified scales. Force Sensing Resistors (FSRs) only detect the presence and relative amount of force, making them unsuitable for precise weighing.

Let's make this simple. A strain gauge is a scientist; an FSR is a light switch. An FSR is typically a polymer film whose electrical resistance changes drastically when you press on it. It’s great at answering yes/no questions like "Is someone sitting in this car seat?" or "Was this button pressed?" It can tell you if there's a little pressure or a lot of pressure, but it can't tell you if that pressure is exactly 10.5 kilograms. Its response is not very repeatable or precise.

A strain gauge, on the other hand, is designed for quantifiable measurement. Its change in resistance is tiny, predictable, and directly proportional to the amount of force applied. This is why we can use it to build scales that are certified for trade. We never use FSRs in our certified scales. Our customers rely on us for legally and commercially valid weights, and for that, only a high-precision technology like a strain gauge will do.

| Feature | Strain Gauge | Force Sensing Resistor (FSR) |

|---|---|---|

| Primary Use | Precise force and weight measurement | Force detection, touch input |

| Precision | High | Low |

| Repeatability | High | Low |

| Typical Application | Industrial scales, test equipment | Buttons, touchpads, occupancy sensors |

| Cost | Moderate | Very Low |

What is a strain gauge used for?

Do you think strain gauges are just for weighing things? This incredibly versatile technology has countless applications across many industries. Limiting your understanding of it could mean missing out on innovative solutions.

A strain gauge's primary job is to measure strain, or the physical deformation of an object. While this is used to calculate weight in scales, it's also used in civil engineering to monitor bridge stress, in automotive testing for component durability, and in medical devices.

Of course, our main focus is using this technology to create world-class weighing systems. But understanding the full range of its applications helps us innovate and build better products for you.

In Our Weighing Systems

We integrate strain gauge load cells into everything from compact bench scales to massive truck scales. We also use them to build fully automated and IoT-enabled weighing systems6 that feed data directly into our clients' software. This allows for real-time inventory tracking7, batching control, and quality assurance, revolutionizing their production flow. We once designed a custom weighing system for a client in the aerospace industry to test the weight distribution on a small composite panel. The principles were exactly the same as our industrial scales, just applied with incredible precision to a unique problem.

Beyond Weighing

The same technology that weighs your products is also keeping people safe every day. Engineers embed them in concrete to monitor the structural health of bridges and dams. Automotive companies use thousands of them to test the stress on a car's chassis during crash tests. Even the medical field relies on them for devices like infusion pumps, where precise force measurement is critical. This versatility proves just how reliable and trusted strain gauge technology is.

Do strain gauges measure force?

Are you getting caught up in the technical details? You hear the term "strain" but you need to measure "force" or "weight." Understanding this distinction is key to trusting the technology.

Indirectly, yes. A strain gauge directly measures strain, which is the deformation of an object. However, force is what causes that strain. By precisely calibrating the system within a load cell, we accurately translate the measured strain into a direct measurement of the applied force or weight.

Think of it like this: a thermometer doesn't directly measure "heat." It measures the expansion of mercury or the change in electrical resistance in a sensor. But we know that expansion is caused by heat, so we calibrate the thermometer to display a temperature in degrees. A strain gauge works the same way. It doesn't have a "force meter" inside it. It simply measures the effect of the force.

The Role of the Load Cell

This is why the load cell is so important. It's not just a random piece of metal. It is a precisely engineered spring-like structure. We design it so that a specific, known force will cause a specific, repeatable amount of strain at the exact spot where we place the strain gauge. The quality of this load cell design and manufacturing is what separates a cheap, unreliable scale from a robust, accurate industrial instrument that will last for years.

Calibration is Key

The final piece of the puzzle is calibration8. This is a critical step in our quality control process. After the scale is built, our technicians use certified standard weights to teach the scale's electronics. They tell the system, "this specific electrical signal from the strain gauge equals exactly 50 kilograms." This process is what turns a simple strain measurement into a reliable and legally valid force measurement you can depend on.

Conclusion

Choosing the right scale technology—strain gauge, force motor, or SAW—depends entirely on your unique business needs, your specific application, and your budget. Let us help you find your perfect fit.

-

Discover the essential features that make industrial scales suitable for various applications. ↩

-

Explore how strain gauge technology can enhance accuracy and reliability in various industrial applications. ↩

-

Understand the critical role of load cells in accurate weight measurement and their applications. ↩

-

Explore the diverse applications of strain gauges beyond weighing, showcasing their versatility. ↩

-

Find out how to choose durable weighing systems that can withstand rigorous use. ↩

-

Learn how IoT technology can revolutionize weighing systems for better data management. ↩

-

Explore how real-time inventory tracking can optimize operations and improve efficiency. ↩

-

Learn about the significance of calibration in ensuring accurate and reliable weight measurements. ↩

Comments (0)