Are small weighing errors bleeding your profits? These tiny mistakes add up, leading to wasted materials and compliance failures. We can help you stop the financial drain and refine your process.

Accurate weighing is non-negotiable for profitability. It stops raw material waste, ensures product quality, and prevents costly shipping errors. Investing in reliable scales and proper procedures directly protects your bottom line.

Running a manufacturing operation for 18 years has taught me one crucial lesson: the most dangerous costs are the ones you don't see. Inaccurate weighing is a perfect example. We often focus on the big-ticket items, but tiny errors in measurement can silently eat away at your margins day after day. It’s like a slow leak in a tire; you might not notice it at first, but it will eventually leave you stranded. I've seen companies lose thousands on wasted materials or over-filled packages, all because their scales were slightly off. These hidden costs1 are real, and addressing them is fundamental to building a stronger, more profitable business. Let's explore how to find and fix these issues for good.

How do you fix an inaccurate weight scale?

Is your scale giving you unreliable readings? This uncertainty disrupts production and quietly drains your budget with every measurement. You need a simple, effective path to get back to accuracy.

First, check the basics. Make sure the scale is on a flat, stable surface, away from vibrations or drafts. Clean any debris from the weighing platform. Then, perform a quick calibration check with a known weight. If it's still off, professional service is your next step.

When a scale is inaccurate, the immediate problem seems small. But the ripple effect is huge. At Weigherps, we see this constantly. An incorrect measurement isn't just a number; it's a decision point that impacts your entire operation. Fixing it starts with understanding the real cost of not fixing it.

The Real Impact of Inaccuracy

Inaccurate weighing creates hidden costs that are often overlooked until it's too late.

- Raw Material Waste: A small over-measurement in a formula, repeated hundreds of times a day, leads to tons of wasted ingredients over a year.

- Product Quality Issues: Inconsistent measurements mean inconsistent products. This can lead to customer complaints, returns, and damage to your brand's reputation.

- Compliance Risks & Fines: For industries with regulated product weights, being off can result in significant fines and legal trouble.

- Increased Logistics Costs: Shipping an overweight package costs you extra in courier fees. Shipping an underweight one can lead to unhappy customers.

A Step-by-Step Troubleshooting Guide

Before calling for service, run through this simple checklist. It solves the most common issues.

| Step | Action | Purpose |

|---|---|---|

| 1. Level & Stabilize | Ensure the scale is on a solid, level surface. | Prevents errors from vibration or tilt. |

| 2. Clean Thoroughly | Remove all dust and residue from the platform. | Debris can affect the weight reading. |

| 3. Check Environment | Eliminate drafts from fans or AC units. | Air movement can push on the scale. |

| 4. Zero the Scale | Press the 'Tare' or 'Zero' button before use. | Establishes a correct starting point. |

| 5. Test with Known Weight | Place a certified weight on the scale. | Verifies if the scale is truly inaccurate. |

When to Call in the Experts

If you've gone through the basic checks and the scale is still inaccurate, it's time for professional help. The internal components, like the load cell or software, may need recalibration or repair. Delaying this step will only allow those hidden costs to grow. Investing in professional service2 is an investment in your company's financial health.

What are the sources of error in weighing?

Your process seems fine, but errors persist. This constant guesswork can make your production data feel unreliable, putting quality and efficiency at risk. You need to identify the root cause.

Most weighing errors come from the environment (like drafts or vibrations), the equipment (calibration drift or wear), or the operator (improper use). Pinpointing which of these is the culprit is the first step toward a permanent solution.

Over the years, I’ve found that many clients focus solely on the scale itself when things go wrong. But a scale is just one part of a larger system. To truly solve inaccuracy, we have to look at the entire context of where and how it's being used. I once visited a factory where a high-precision scale was placed right next to a heavy stamping machine. The scale was perfect, but the constant vibrations from the stamper made accurate readings impossible. It’s crucial to consider every factor that could influence the result, not just the hardware. This holistic view is how we design robust weighing solutions for our clients.

Environmental Factors You Can't Ignore

Your scale is sensitive, and its surroundings matter.

- Vibrations: Nearby machinery, foot traffic, or even building tremors can interfere with sensitive load cells.

- Air Currents: Drafts from open doors, windows, or HVAC systems can exert pressure on the scale platform, skewing results.

- Temperature: Extreme heat or cold can cause the scale's electronic and mechanical components to expand or contract, leading to drift.

- Static Electricity: In dry environments, static can build up and create a magnetic force that affects the measurement.

The Human Element: Operator Influence

Even the best scale is only as good as the person using it.

- Incorrect Placement: Placing items off-center on the scale can lead to inaccurate readings.

- Rushing the Process: Not allowing the scale to stabilize before recording the weight is a common mistake.

- Improper Taring: Forgetting to zero out the weight of a container before adding the product is a frequent source of error.

- Lack of Training: If operators don't understand the equipment's features and limitations, errors are inevitable.

Equipment Health: The Scale Itself

Sometimes, the problem really is the machine.

- Calibration Drift: All scales lose accuracy over time. Without regular recalibration, their readings will slowly become unreliable.

- Physical Damage: A dropped object or a harsh cleaning can damage the sensitive load cell underneath the platform.

- Outdated Software: For digital and IoT scales, outdated firmware can cause compatibility or performance issues. As a manufacturer specializing in these systems, we know how vital software updates are for maintaining peak performance and security.

What role does regular calibration play in accuracy?

Your scales seem to be working just fine. But are they slowly drifting out of spec? This quiet inaccuracy can build up, causing a major quality or compliance issue unexpectedly.

Regular calibration is your quality assurance. It systematically checks and corrects your scale's accuracy against a certified standard. This proactive process ensures your measurements are always reliable, preventing small drifts from becoming major, costly problems.

I talk to purchasing managers all the time who are focused on the initial cost of equipment. That's understandable. But I always stress that the total cost of ownership3 is what really matters. A scale that isn't calibrated regularly is a liability. Think of it like a car. You wouldn't skip oil changes to save money, because you know it would lead to a much more expensive engine failure down the road. Scale calibration is the same. It's a small, predictable maintenance cost that prevents unpredictable and massive expenses from production errors, material waste, or regulatory fines. It protects your initial investment and your bottom line.

What is Calibration, Exactly?

Calibration is not just a simple check. It's a formal process of comparing your scale's measurement to a known, verified mass (a certified calibration weight). If there's a difference between what the scale reads and what the true weight is, an adjustment is made to bring the scale back into alignment. This process is essential for traceability and ensuring your measurements are legally and scientifically valid. It's the only way to be certain your scale is performing as expected.

How Often Should You Calibrate?

The ideal calibration frequency depends on several factors.

| Usage Level | Environment | Criticality of Measurement | Recommended Frequency |

|---|---|---|---|

| High | Harsh (dust, moisture) | High (e.g., pharmaceutical) | Monthly to Quarterly |

| Medium | Stable, clean | Moderate (e.g., food packaging) | Semi-Annually |

| Low | Laboratory | Low (e.g., internal checks) | Annually |

This table is a general guide. Your own quality standards or regulatory requirements may demand a more frequent schedule. The key is consistency.

The Difference Between User Checks and Professional Calibration

It's important to understand that a quick check by your staff is not the same as a professional calibration.

- User Checks: An operator using a known weight to see if the scale is "in the ballpark." This is a great daily or weekly practice to catch major drift.

- Professional Calibration: A trained technician uses a full range of certified, traceable weights to test the scale across its entire capacity. They make precise adjustments and provide a formal certificate for your records, which is often required for audits and compliance.

Both are important, but one cannot replace the other. Regular user checks4 handle day-to-day consistency, while professional calibration ensures long-term, certified accuracy.

How can you build a more error-proof weighing process?

You've fixed your scale, but mistakes are still happening. The issue might be bigger than just the hardware. Your entire process could be the source of these recurring, costly errors.

To create a process that prevents errors, you need a system. This involves standardizing your procedures, properly training your team, controlling the weighing environment, and scheduling regular equipment maintenance. A strong process turns weighing from a variable into a constant.

As an OEM/ODM manufacturer, we don't just build scales; we build weighing systems. We work with clients to understand their full workflow because we know that the hardware is only half the solution. A technical director for a major software company once told me, "I need a system that my team can't get wrong." That really stuck with me. It’s why we focus on creating intuitive interfaces, integrating with existing software, and providing IoT capabilities5 that can automate data logging. The goal is to design a process where the correct way to do things is also the easiest way. This reduces human error and ensures the data you collect is consistently reliable.

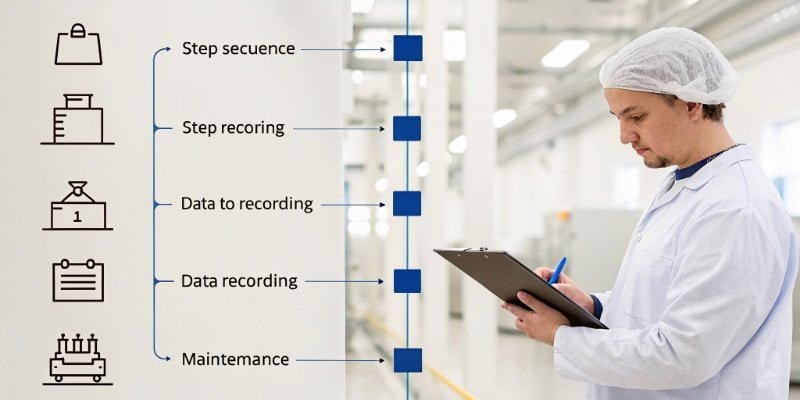

Standard Operating Procedures (SOPs)

Your first step is to create a clear, simple document that outlines the exact steps for every weighing task. This removes guesswork. An effective SOP should include:

- Step-by-step instructions for operating the scale.

- How to clean and care for the equipment.

- When and how to perform daily user checks.

- Who to contact if an error is found.

This ensures everyone on your team performs the task the same way, every single time.

Operator Training and Empowerment

Your team is your first line of defense against inaccuracy. Proper training is not an expense; it's an investment. Ensure your operators not only know how to use the equipment but also understand why accuracy is so important to the company's success. When they see how their role impacts material costs and product quality6, they become more diligent. Empower them to flag potential issues with equipment or the environment before they become bigger problems.

Creating a Stable Weighing Environment

Don't let your surroundings sabotage your accuracy. Designate a specific area for high-precision weighing.

- Use a sturdy, vibration-proof weighing table.

- Install draft shields for sensitive scales.

- Control for extreme temperature fluctuations.

- Implement anti-static measures in dry environments.

A controlled environment gives your scale the best possible chance to perform correctly.

Choosing the Right Equipment

Finally, the right tool makes the job easier and more reliable. When selecting a scale, consider not just its capacity and readability, but also its suitability for your process. As a provider of custom weighing systems7, we help clients choose solutions that solve their specific problems. This could mean a scale with built-in software to guide operators through a recipe, or an IoT-enabled scale that automatically sends data to your ERP system, eliminating manual entry errors. Investing in the right technology from the start is the most effective way to build a truly error-proof process.

Conclusion

Accurate weighing is not just a technical task; it's a vital business function. By fixing inaccuracies and building a robust process, you protect your materials, your quality, and your profits.

-

Understand the unseen financial impacts of weighing inaccuracies on your business. ↩

-

Learn when it's necessary to seek professional help for scale calibration and maintenance. ↩

-

Explore the concept of total cost of ownership and its relevance to scale investments. ↩

-

Explore the differences between user checks and professional calibration for scales. ↩

-

Discover the advantages of integrating IoT technology into your weighing processes. ↩

-

Discover effective practices to ensure consistent product quality and customer satisfaction. ↩

-

Explore how custom weighing systems can address specific challenges in your production process. ↩

Comments (0)