Are you curious about the magic inside a digital scale? Trusting a "black box" for your business is risky. Let's open it up and see exactly how it works.

A digital scale uses a sensor called a load cell to measure weight. It converts the force of an object into a tiny electrical signal. This signal is then amplified, converted into a digital number, and processed by a microchip to display the final, accurate weight.

That's the quick answer. But as a manufacturer with 18 years of experience, I know the details are what separate a good scale from a great one. The real magic isn't just one component, but how they all work together perfectly. As a software vendor, knowing this process can make your integration projects much smoother. Let's break it down piece by piece.

How does a digital scale actually measure weight?

Placing an item on a scale gives an instant reading. But not knowing the process makes it hard to trust the accuracy that is so critical for your operations.

A digital scale measures weight by converting physical force into a digital value. An object's weight deforms a sensor, creating an electrical signal. This analog signal is cleaned, amplified, converted to digital data, and processed by a microprocessor to show a precise weight reading.

In my years of building industrial scales1, I've seen that understanding this entire workflow is crucial for troubleshooting and integration. The journey from a physical object to a number on a screen happens in four distinct steps. We meticulously engineer each stage to ensure the final result is one our clients can rely on for their business.

Step 1: Sensing the Force

When you place an object on the scale, its weight is a force. This force causes a component inside, the load cell2, to bend or deform just a tiny, almost imperceptible amount. This physical reaction is the very first step in any measurement.

Step 2: Creating an Electrical Signal

This tiny deformation changes the electrical resistance in sensitive gauges attached to the load cell. This change produces a very weak voltage signal. The key here is that the signal's strength is directly proportional to the weight applied. Heavier object, stronger signal.

Step 3: From Analog to Digital

The raw signal from the sensor is weak and can be affected by electrical noise. It first passes through an amplifier3 and a filter. Then, an Analog-to-Digital Converter (ADC)4 translates this clean analog voltage into a digital number that a computer can understand.

Step 4: Computing and Displaying

Finally, a microprocessor (MCU)5 takes this digital number. It runs calculations for calibration and converts it into your desired unit (like kilograms to pounds). It then sends the final, accurate weight to the display screen.

What is the main sensor inside a digital scale called?

You know a sensor does the work, but what is its actual name? Calling it just "a sensor" is vague and doesn't help you evaluate the quality or performance for your projects.

The main sensor in a digital scale is called a load cell. It's the core component responsible for sensing weight. Most high-quality scales use a strain gauge load cell, known for its incredible accuracy, stability, and durability in tough industrial environments.

The load cell is truly the heart of any digital scale6. I like to think of it as the muscle of the system. When weight is applied, a specially designed metal element inside the load cell deforms. This is where the conversion from physical force to an electrical signal7 begins, and its quality dictates the scale's potential.

The Strain Gauge Principle

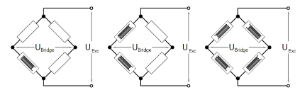

Glued to this metal element are very sensitive resistors called strain gauge8s. As the metal bends, the strain gauges stretch or compress. This changes their electrical resistance. This change, though tiny, is perfectly measurable. A circuit configuration called a Wheatstone bridge9 then detects this resistance change and converts it into a very small, but proportional, voltage output.

Common Types of Load Cells

While several types exist, the strain gauge is the industry standard for a good reason. At Weigherps, we almost exclusively use strain gauge load cells in our industrial scales. They provide the best combination of performance, reliability, and cost-effectiveness that our clients, especially those in demanding sectors, require.

| Load Cell Type | Principle | Best For |

|---|---|---|

| Strain Gauge | Measures change in electrical resistance. | High accuracy, stability (Industrial/Commercial) |

| Capacitive | Measures change in capacitance. | Lower cost, consumer-grade scales10. |

| Piezoelectric | Generates voltage under pressure. | Dynamic weighing, less for static accuracy. |

How does the technology in a digital scale convert pressure into a number?

A sensor creates a signal, but how does that become a usable number? This part can seem like a black box, and any uncertainty here can lead to software integration headaches down the line.

The conversion happens in two stages. First, an amplifier boosts the load cell's weak, analog voltage signal and a filter cleans it. Then, an Analog-to-Digital Converter (ADC) chip measures this clean signal and translates it into a digital value.

The signal that comes from the load cell is tiny, measured in millivolts. It is also full of electrical "noise" from the surrounding environment. You can't just send this directly to a processor; it needs to be properly prepared. As manufacturers, we pay extremely close attention to this stage, as it directly impacts the scale's precision.

Amplification and Filtering

First, the signal goes to an instrumentation amplifier (INA). Its job is to make the signal much stronger without adding more distortion. You can think of it like turning up the volume on a very quiet, clear voice. At the same time, a low-pass filter removes any high-frequency interference, ensuring the signal is stable and clean.

Analog-to-Digital Conversion (ADC)

The clean, amplified signal is still an analog wave, which is a continuous signal. A computer, however, only understands discrete numbers. The Analog-to-Digital Converter (ADC)4 is the translator. For high-precision industrial scales, we use high-resolution ADCs11, typically 24-bit chips like the well-regarded HX711. A higher bit count means the ADC can slice the analog signal into many more smaller steps, which results in a much more precise final weight. For the accuracy our clients require, this component is non-negotiable.

What makes the load cell in a digital scale so accurate?

You know a load cell is the sensor. But why are some scales far more accurate than others, even when they seem to use the same type of technology? The secret is in the details.

A load cell's accuracy comes from the high-quality materials of its flexible body, the precision of its strain gauges, and a stable circuit design. But true accuracy also depends on the microprocessor (MCU), which corrects for temperature, performs digital filtering, and manages calibration.

A load cell's accuracy is not a single feature. It is the result of several critical factors all working together in perfect harmony. In my 18 years of experience, I can tell you that you cannot cut corners on any of these if you expect a reliable and professional-grade product.

Physical Construction

It all starts with the physical body of the load cell, which is often made of high-quality aluminum alloy or stainless steel. It must deform predictably under load and, most importantly, return to its exact original shape every single time. The strain gauges bonded to it must also be of very high quality to ensure their electrical resistance changes consistently with every measurement.

The Brains of the Operation: The MCU

However, the physical parts are only half of the story. The microprocessor (MCU)5 is the brain that brings it all together and unlocks true precision. It runs sophisticated software algorithms to:

- Calibrate: It stores the "zero" point and a "known weight" point, creating a precise reference map for all measurements.

- Filter: It performs additional digital filtering on the signal from the ADC to smooth out tiny fluctuations, giving you a stable, readable number.

- Compensate: High-end industrial scales use the MCU to compensate for environmental factors like temperature changes, which can slightly affect the load cell's performance.

This is exactly why our quality control department is so rigorous. Every product we ship undergoes comprehensive testing to ensure the hardware and software are perfectly harmonized for maximum accuracy.

Conclusion

In short, a digital scale combines a precision load cell, clean signal processing, and smart software. This synergy turns physical force into the trustworthy digital data your business needs.

-

Explore the characteristics that define reliable industrial scales. ↩

-

Understanding load cells is crucial for evaluating scale performance and accuracy. ↩

-

Understanding amplifiers can help you grasp the signal processing in scales. ↩

-

Discover how ADCs translate signals for accurate digital readings. ↩ ↩

-

Understanding the MCU's function can enhance your knowledge of scale technology. ↩ ↩

-

Explore the technology behind digital scales to ensure reliable measurements for your business. ↩

-

Explore the process of signal generation for better insights into scale accuracy. ↩

-

Learn about strain gauges to appreciate their role in precision measurement. ↩

-

Discover the Wheatstone bridge's role in measuring resistance changes. ↩

-

Understanding the differences can help you choose the right scale for your needs. ↩

-

Find out how high-resolution ADCs improve measurement precision. ↩

Comments (0)