Struggling with inaccurate industrial measurements? This inconsistency disrupts production and increases costs. A high-quality load cell is the solution you need for reliable, a precise weighing.

A load cell is a transducer that converts force into a measurable electrical output. In industries, it is the core component of weighing systems, directly determining the accuracy and capacity of scales. This ensures precise material handling, batching, and quality control processes.

This little device is the unsung hero of countless industrial processes. I've spent nearly 20 years in this industry, and I've seen firsthand how the right load cell1 can transform an operation. But how exactly does it work, and why is it so critical? Let's dive deeper and uncover the mechanics and significance of load cells in today's demanding industrial environments.

What Are Load Cells and How Do They Function in Industrial Applications?

Confused by how a simple component measures massive weights? This lack of understanding can make choosing the right equipment difficult. Let's simplify how load cells work for you.

Load cells work on the principle of strain gauges. When a force is applied, the load cell's body deforms slightly. This changes the electrical resistance of the strain gauges attached to it. This change is then converted into a digital signal representing the weight.

At its heart, a load cell is a surprisingly straightforward device that performs a critical task. For years, I've explained this to clients who are often surprised by the elegant simplicity behind such a robust tool. The entire process relies on a few key steps that turn physical force into useful data.

The Core Principle: Strain Gauges

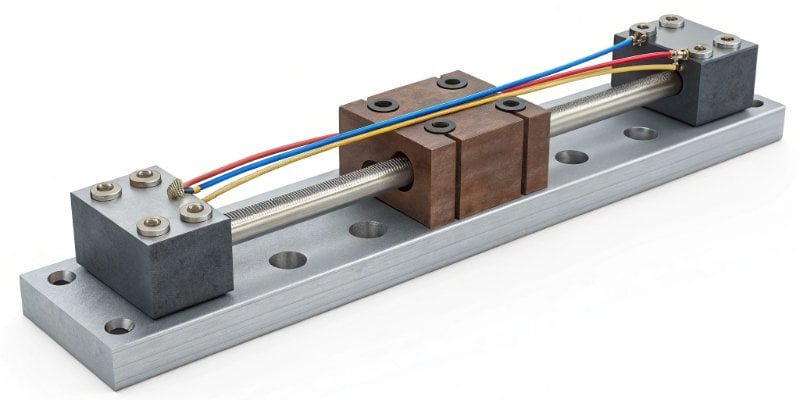

Most industrial load cells we produce use strain gauges2. A strain gauge is a very fine wire or foil set up in a grid pattern. We bond this grid to a strong but flexible part of the load cell's structure, often a precisely machined piece of steel or aluminum. When a weight or force is applied, this metal structure bends or deforms by a tiny, almost invisible amount. Because the strain gauge is bonded to it, the gauge stretches or compresses along with the structure. This physical change alters the flow of electricity through the wire.

Converting Force to Data

The change in electrical resistance is very small, but it's directly proportional to the force applied. The load cell contains a setup, usually a Wheatstone bridge circuit3, that can measure this tiny change with incredible precision. This electrical signal is then sent to a weight indicator or a computer system. The system's software, which you as a software vendor would develop or integrate with, interprets this signal and displays it as a weight measurement, like kilograms or pounds.

| Step | Action | Result |

|---|---|---|

| 1. Apply | A force (weight) is placed on the scale. | The load cell's metal body slightly deforms. |

| 2. Deform | The strain gauge bonded to the body stretches/compresses. | The physical dimensions of the strain gauge wire change. |

| 3. Measure | An electrical current passes through the strain gauge. | The electrical resistance of the wire changes. |

| 4. Convert | The change is read by electronics. | A readable weight signal is generated and sent out. |

Why Are Load Cells Essential Components in Modern Industries?

Are you overlooking small components in your system? This can lead to major failures and costly downtime. Discover why the load cell is a component you just can't afford to ignore.

Load cells are essential because they provide the foundational data for countless industrial processes. They ensure product quality, process control, safety, and regulatory compliance. Without accurate weight data from load cells, automation and efficiency would be impossible in many industries.

In my experience, many people think of scales as simple devices for buying and selling goods. But in modern industry, the data from a load cell is the starting point for so much more. It’s the eyes and ears for automated systems. Without this critical data point, many of the efficiencies we take for granted today would simply disappear.

The Foundation of Process Control

Think about a factory making paint. The final color depends on adding exact amounts of different pigments. A load cell under each mixing tank provides real-time weight data to the control system. This allows the system to open and close valves with perfect timing, ensuring every single batch is the same color. This level of automation4 relies completely on the reliable data from the load cell. It’s not just about weighing; it's about precise control.

Ensuring Safety and Compliance

Load cells also play a huge role in safety. For example, cranes use load cells to prevent overloading, which could lead to catastrophic failure. In logistics, our weighbridge scales use multiple load cells to weigh trucks. This ensures they are not over their legal weight limit, helping companies avoid heavy fines and keeping the roads safer for everyone. The data is clear and legally defensible, all thanks to a well-calibrated load cell system.

Driving Efficiency and Automation

Ultimately, load cells drive efficiency. They reduce the need for manual checks, minimize material waste, and speed up production. When your software receives clean, accurate weight data, it can make smarter decisions. This could be anything from managing inventory in a silo to controlling a high-speed filling line. The load cell is the first link in a long chain of automation that leads to higher profits.

How Are Load Cells Used to Enhance Accuracy in Various Industries?

Are minor inaccuracies costing your business a fortune? These small errors add up, affecting profits and reputation. Let's look at how the right load cells deliver the precision you need.

Load cells enhance accuracy by providing precise, repeatable weight measurements. In manufacturing, they ensure correct mixture ratios. In logistics, they verify shipment weights for billing. In pharmaceuticals, they guarantee exact dosages, all of which minimize waste and ensure consistent product quality.

I remember a client in the chemical industry who was struggling with inconsistent batches. Their final product quality varied from one day to the next. After visiting their plant, we realized their existing load cells were not sensitive enough for the small, critical ingredients they were adding. We installed a new system with higher-precision load cells. Within a month, they achieved a batch consistency of over 99.8%. This single change saved them thousands in wasted materials and improved their customer satisfaction. My insight is that the load cell directly decides the final accuracy5.

Precision in Manufacturing and Batching

In any industry that mixes ingredients, from concrete to cookies, accuracy is everything. An error of just 0.5% in a large batch of food product can alter the taste and lead to an entire production run being rejected. High-quality load cells provide the needed resolution to measure each ingredient down to the gram, ensuring a perfect mix every time. This protects brand reputation and reduces waste.

Accuracy in Logistics and Trade

When goods are sold by weight, accuracy is directly tied to profit. Consider a scrapyard. If their truck scale is inaccurate by just a small percentage, they could be losing thousands of dollars every day, either by overpaying for scrap coming in or under-charging for materials going out. We provide load cells for weighbridges that are certified for trade use, guaranteeing fairness and profitability for our clients.

High-Stakes Weighing in Pharmaceuticals

| Industry | Application | Why Accuracy is Critical |

|---|---|---|

| Food & Beverage | Ingredient Batching | Product consistency, taste, and safety. |

| Logistics | Shipping & Receiving | Fair billing and legal compliance (avoiding fines). |

| Pharmaceutical | Formulation | Patient safety and efficacy of medicine. |

| Agriculture | Silo Weighing | Correct inventory management, preventing spoilage. |

In the pharmaceutical world, accuracy isn't about profit; it's about patient safety. The active ingredients in medicine are often measured in micrograms. The load cells used in these applications are incredibly sensitive. They operate in controlled environments to ensure that every pill or vial contains the exact, life-saving dose. There is zero room for error, and it all starts with the load cell.

What Factors Determine the Selection of Load Cells for Industrial Use?

Overwhelmed by the technical specs when choosing a load cell? Making the wrong choice can lead to system failure. Let's break down the key factors for a perfect match.

Key factors for selecting a load cell include its capacity, accuracy class, material, environmental sealing (IP rating), and output type. The specific application and operating environment are the most critical determinants for the final choice.

Choosing the right load cell is a process we guide our clients through every day. It's not about picking the most expensive or highest-capacity6 option. It’s about finding the perfect fit for the job to ensure long-term reliability and performance. A purchasing manager or technical director needs to balance performance with cost, and understanding these factors is key.

Matching Capacity and Accuracy to the Task

First, you need to know the maximum weight you plan to measure. This is the capacity. You should always choose a load cell with a capacity that is safely above your maximum load. Next is accuracy. For simple inventory weighing, a standard accuracy might be fine. But for chemical batching, you'll need a much higher accuracy class (like C3 or C6). As I mentioned earlier, many high-precision requirements can only be met by choosing a better load cell. This is often the most important decision.

Considering the Operating Environment

Where will the load cell be used? A load cell in a dry, clean room has very different requirements than one on a fishing boat or in a chemical plant. This is where materials and sealing come in.

- Material: We typically use alloy steel for general use and stainless steel for corrosive or wash-down environments.

- IP Rating: This number tells you how well the load cell is sealed against dust and water. An IP67 rating means it can be submerged in water for a short time, while an IP68 rating means it can be permanently submerged.

Integration and Output Signals

Finally, how will the load cell connect to your system? This is especially important for you as a software provider.

- Analog Output: This is the traditional standard, providing a raw millivolt signal that is processed by an external device.

- Digital Output: A digital load cell has onboard electronics to process the signal itself. It provides a cleaner, more stable data stream that is easier to integrate. Digital load cells can also offer advanced features like internal diagnostics, which your software can use to monitor the health of the weighing system.

Understanding these factors will help you make a more informed decision and build a more reliable system for your customers.

Conclusion

Choosing the right load cell is crucial for accuracy and efficiency. It is the heart of any weighing system, directly impacting your product quality and operational success.

-

Explore this link to understand the fundamental role of load cells in industrial applications. ↩

-

Find out how strain gauges operate and their critical role in load cell technology. ↩

-

Understand the Wheatstone bridge circuit's application in measuring electrical resistance changes. ↩

-

Explore how automation enhances efficiency and reduces manual labor in industries. ↩

-

Discover the methods used to ensure accuracy in various industrial processes. ↩

-

Explore how to determine the appropriate capacity for load cells in various applications. ↩

Comments (0)