Struggling with generic software that doesn't fit your unique industrial weighing process? This disconnect can lead to inefficiencies and data errors. The solution lies in highly customized intelligent weighing software.

Industrial intelligent weighing software is characterized by its ability to be highly customized. It integrates seamlessly with specific hardware and a client's existing backend systems. This allows for tailored data collection, process automation, and streamlined data integration, ultimately improving efficiency and accuracy in industrial operations.

This level of customization means the software is built around your workflow, not the other way around. But what exactly is industrial weighing1, and how do these intelligent systems truly enhance the process? Let’s explore the fundamentals to understand the full impact of this technology.

What is industrial weighing?

Are you facing challenges in accurately measuring heavy or bulky items in a tough environment? Standard scales often fail in these settings. Industrial weighing provides the robust and precise solution you need.

Industrial weighing involves the use of scales specifically designed for manufacturing, logistics, and other industrial environments. These scales are built to be durable and provide accurate readings for a wide range of materials, from small components to large cargo.

Industrial scales are essential tools for ensuring quality control, managing inventory, and facilitating fair trade. They are designed to withstand harsh conditions like dust, moisture, and vibrations, which are common in industrial settings. I've seen firsthand how a reliable industrial scale can streamline operations. For one of our clients in the logistics sector, integrating a robust platform scale into their shipping department eliminated errors in billing and improved overall efficiency. The key is that these scales are not just about measuring weight; they are about providing reliable data that can be trusted to make critical business decisions. This often involves integrating the scale directly into a production line or a company's data management system2. The ability to have a tailored solution that seamlessly fits into an existing process is what makes industrial weighing so powerful. It's about finding the right tool for a specific, demanding job.

How accurate are industrial weighing scales?

Worried that your current scales aren't providing the precision you need? Inaccuracy in industrial weighing can lead to significant financial losses. High-quality industrial scales, however, offer remarkable accuracy for dependable results.

The accuracy of industrial weighing scales can be very high, often to within one-tenth of one percent. For instance, a scale with a 5,000-pound capacity is expected to be accurate within plus or minus five pounds. However, this accuracy can be influenced by several factors.

The accuracy of an industrial scale depends on its design and the technology it uses. There are different accuracy classes for industrial scales, with Class I being the most accurate. The resolution of the scale also plays a crucial role; a higher resolution means more precise measurements. In my experience, environmental factors are just as important as the scale's technical specifications. Things like vibrations from nearby machinery, air currents, and even dust buildup under the scale can affect readings. To maintain accuracy, regular calibration3 is essential. This involves checking the scale against certified weights and making adjustments as needed. I always advise our clients to establish a routine calibration schedule. This proactive approach ensures their scales provide consistently reliable data, which is fundamental for quality control and efficient operations.

| Accuracy Class | Typical Application |

|---|---|

| Class I | Laboratory, high-precision weighing |

| Class II | Precious metals, laboratory |

| Class III | Commercial, industrial |

| Class IV | Highway weighing |

What is the principle of electronic weighing machine?

Confused by the inner workings of an electronic scale? This lack of understanding can make it hard to choose the right one. The principle is straightforward: it converts the force of weight into an electrical signal.

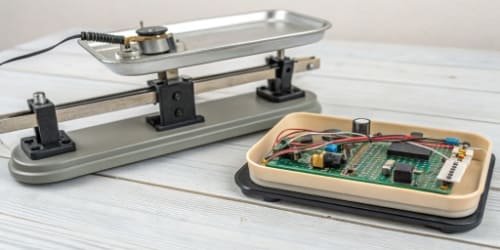

An electronic weighing machine operates by using a sensor to transform the physical force of an object's weight into an electrical signal. This signal is then processed and displayed as a weight reading. The core component in this process is typically a load cell.

At the heart of most electronic scales is a load cell4, which is a transducer that converts force into a measurable electrical output. When you place an object on the scale, it causes a slight deformation in the load cell. Attached to the load cell is a strain gauge, which is a sensor whose resistance changes when it's stretched or compressed. This change in resistance is proportional to the weight on the scale. I remember explaining this to a purchasing manager who was hesitant about the reliability of electronic scales. Once he understood that it's a direct, physical measurement being converted, he felt much more confident. This electrical signal is then amplified and converted from analog to digital form, which is then processed to give an accurate weight reading. It's a simple, yet elegant, principle that has revolutionized how we measure weight.

What are the functions of a weighing scale?

Think a weighing scale is just for measuring weight? You might be missing out on functions that could streamline your operations. Modern scales offer a range of capabilities beyond basic measurement.

A weighing scale's primary function is to measure weight or mass. However, modern industrial scales have evolved to perform multiple functions, including counting, check-weighing, and data collection, making them integral parts of a production process.

Beyond simply telling you how heavy something is, a modern industrial scale can be a powerful data collection5 tool. Many scales now come with connectivity options like Bluetooth and Wi-Fi, allowing for seamless integration with other devices and software systems. This means weight data can be automatically logged, which is crucial for traceability and quality control. We had a client in the food industry who used the check-weighing6 function on their scales to ensure every package met the specified weight, which significantly reduced product giveaway. Another key function is parts counting7. For businesses that deal with large quantities of small, identical items, a counting scale can save a tremendous amount of time and reduce human error. The ability to customize the software on these scales means we can create a solution that perfectly matches a client's workflow, turning a simple weighing device into a multi-functional tool that enhances productivity.

Conclusion

Industrial intelligent weighing software offers highly tailored solutions. By integrating with your specific hardware and backend systems, it significantly improves the efficiency, accuracy, and data management of your weighing processes.

-

Get insights into the role of industrial weighing in various sectors. ↩

-

Discover methods for effective integration of scales with your data systems. ↩

-

Understand the significance of regular calibration for maintaining scale accuracy. ↩

-

Learn about the critical role of load cells in accurate weight measurement. ↩

-

Discover effective strategies for accurate data collection to enhance your operations. ↩

-

Find out how check-weighing can enhance quality control in production. ↩

-

Learn how parts counting features can save time and reduce errors in operations. ↩

Comments (0)