Feeling lost in the world of industrial scales and worried about making a costly mistake? Choosing the wrong one can disrupt your entire workflow. We are here to help.

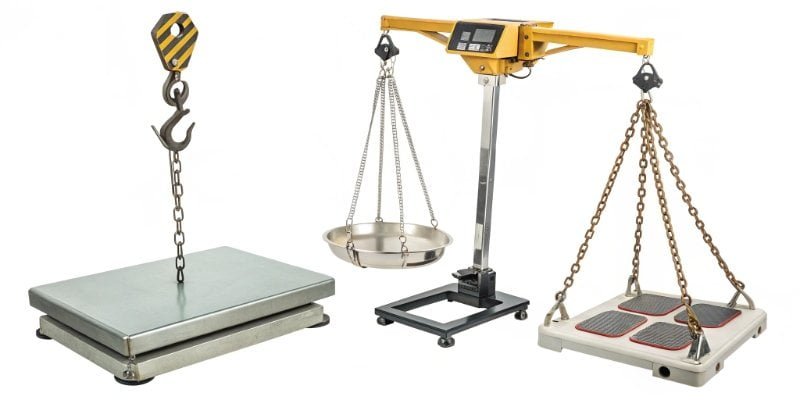

The main differences are size, capacity, and where you use them. Platform scales sit on the floor for heavy goods, bench scales rest on a table for smaller items, and crane scales hang to weigh suspended loads. Your choice depends entirely on what you weigh and where you weigh it.

Choosing the right scale is critical for your business's efficiency and accuracy. I’ve seen clients struggle with scales that were too small for their products or not durable enough for their environment. It’s a common problem, but one that is easy to solve with a little knowledge. To make the best decision for your operations, it’s important to understand the specific strengths of each type. Let's break down the details so you can choose with confidence.

What is the difference between a platform scale and a bench scale?

Are you trying to decide between a platform and a bench scale but are unsure of the key differences? Picking the wrong one can slow down your work and waste money.

The primary difference is their size and application. Platform scales are large, floor-mounted units designed for heavy items like pallets. Bench scales are small, portable scales that sit on a workbench for weighing smaller parts, packages, or ingredients with high precision.

When we advise our clients, the first question we always ask is, "What are you weighing, and where?" The answer almost immediately points toward either a platform or a bench scale. They are both fundamental tools, but they serve very different roles.

I remember a software company we worked with. They were developing a new warehouse management system for a client. They initially planned to use bench scales1 everywhere, but their client needed to weigh incoming pallets. We helped them integrate large platform scales2 at the loading docks and bench scales at the packing stations. This simple distinction was key to their project's success.

To help you see the differences clearly, let's compare them side-by-side.

Key Distinctions: Platform vs. Bench Scales

The best way to understand the right fit is to look at their core features.

| Feature | Platform Scale | Bench Scale |

|---|---|---|

| Location | On the floor | On a bench, table, or counter |

| Capacity | High (500 kg - 10,000 kg+) | Low to Medium (1 kg - 300 kg) |

| Size | Large footprint (e.g., 1m x 1m) | Small, compact footprint |

| Portability | Usually fixed, some are portable | Highly portable, often with battery power |

| Best For | Pallets, crates, vehicles, containers | Parts, ingredients, small packages, mail |

A platform scale is your heavy-lifter. It's built to withstand the tough environment of a warehouse floor, with strong impact resistance. On the other hand, a bench scale is all about precision3 and convenience for smaller tasks. Think of it as the difference between weighing a whole truckload of potatoes and weighing a single bag for sale in a store.

What are the 4 main types of industrial scales?

People often talk about different scales, but what are the main types you should know? Not knowing can lead to confusion and a poor purchasing decision. Let’s clarify the essentials.

Four common industrial types are bench scales for worktops, floor scales for heavy loads, crane scales for suspended weighing, and counting scales for inventory. Each type is designed for a specific task to ensure accuracy and efficiency in your operations.

While the world of weighing is vast, most industrial needs can be met by understanding four key categories. At Weigherps, we focus on helping clients find the perfect match within these groups. By focusing on the job you need to do, you can quickly narrow down your options from dozens to just a few.

For instance, many of our software provider clients are surprised by the capabilities of modern counting scales4. They are perfect for integrating with inventory management software, turning a tedious manual task into an automated, error-free process. One client in the electronics component business completely eliminated their manual inventory checks this way, saving hundreds of hours a year.

Here’s a deeper look at these four workhorse categories.

Exploring the Core Four

Each scale type is a specialist, designed to perform its function flawlessly within a specific environment.

| Scale Type | Primary Function | Common Environment | Key Feature |

|---|---|---|---|

| Bench Scale | Weighing smaller, lighter items. | Workshops, labs, packing stations. | Portability and high precision. |

| Floor/Platform Scale | Weighing large, heavy items. | Warehouses, loading docks, production lines. | High capacity5 and durability6. |

| Crane Scale | Weighing suspended loads in the air. | Foundries, shipping ports, construction sites. | Safety features and remote operation. |

| Counting Scale | Counting large quantities of identical items. | Stockrooms, assembly lines, dispatch areas. | Averages piece weight for quick counts. |

Understanding these categories is the first step. The next is to think about how they fit into your workflow. Do you need to weigh items on a production line? A bench or floor scale is likely your answer. Do you need to weigh large, awkwardly shaped objects as they are being moved? A crane scale is the only safe and efficient way to do that. And for any business managing small parts inventory, a counting scale is a game-changer.

What are the different types of platform scales?

Do you think all platform scales are basically the same? This common idea can lead you to buy a scale that doesn't fit your space or workflow, causing daily frustration.

Platform scales mainly differ in their design and installation. The main types are low-profile scales for easy pallet jack access, pit-mounted scales for a flush floor surface, and portable scales on wheels. The right one depends on your space and equipment.

A platform scale isn't just a platform scale. After 18 years in this business, I've seen how a small design choice can make a huge difference in daily operations. The goal is to make the process of getting goods on and off the scale as seamless as possible. Choosing the right type of platform scale is crucial for maintaining a smooth and efficient workflow in a busy industrial environment.

Let’s explore the three main designs to see which one would work best for you.

Low-Profile Platform Scales

These scales are the most common type. They sit directly on the floor and are very thin, usually only a few inches high. Because they're not flush with the ground, they require ramps for equipment like pallet jacks or carts to roll onto them. They are relatively easy to install and can be moved if your warehouse layout changes. This makes them a flexible and cost-effective choice for many general-purpose weighing applications.

Pit-Mounted Platform Scales

For the most seamless workflow, a pit-mounted scale is the ultimate solution. As the name suggests, we install this scale in a pit, making its surface perfectly flush with the surrounding floor. This means forklifts, pallet jacks, and carts can move over it from any direction without needing ramps. It's ideal for high-traffic areas and automated conveyor systems, where you can't have any obstructions. This is a top choice for clients integrating scales into a larger, automated system.

Portable Platform Scales

Sometimes, you need to bring the scale to the goods, not the other way around. Portable platform scales are the answer. They are equipped with wheels and a handle, allowing one person to easily move them around a warehouse or workshop. While their capacity might be slightly lower than a fixed scale, their flexibility is unmatched for businesses with changing needs or limited space.

What are the different types of weighing scales?

Are you feeling overwhelmed by all the different weighing scales on the market? It's easy to get lost in the options and delay your project. Let's simplify the main categories.

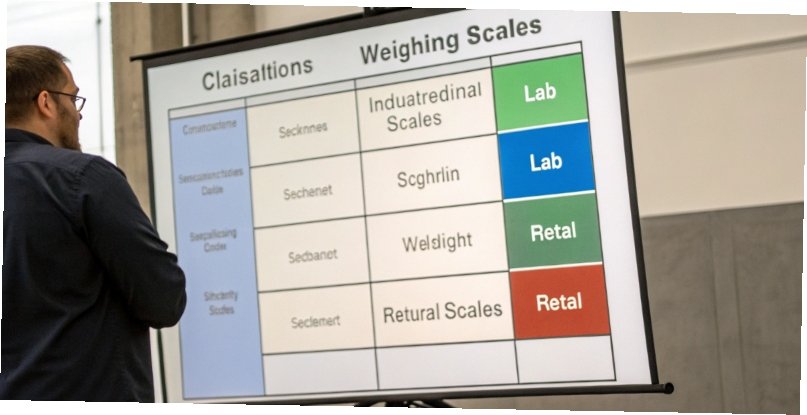

Weighing scales are often grouped by technology (mechanical vs. electronic) or by use (industrial, lab, retail). Today, electronic scales dominate with their high precision and connectivity features. The best type for you depends entirely on your specific industry and needs.

When customers ask me this question, I tell them to think less about the individual scales and more about the big picture. All scales do one thing—measure mass—but how they do it and what they are built for makes all the difference. As a manufacturer, we see a clear divide between scales built for different purposes. A scale designed for a laboratory has different priorities than one built for a steel mill.

As experts in industrial weighing, our focus is naturally on scales built for tough environments and heavy use. This is where durability, reliability, and connectivity to other systems are most important. Here's a simple way to categorize the vast world of scales.

A Broad Classification of Scales

We can group scales in a few logical ways to make them easier to understand.

| Classification | Types Included | Most Common Use Case |

|---|---|---|

| By Technology | Mechanical (Springs/Balances), Electronic (Load Cells) | Older or simple applications, Modern precision weighing |

| By Application | Industrial, Laboratory, Retail, Medical | Warehouses, R&D labs, grocery stores, hospitals |

| By Precision | High Precision, General Purpose | Analytical chemistry, Shipping and logistics |

As you can see, the categories overlap. For example, we produce electronic industrial scales7 for general-purpose use, but we can customize them for higher precision if needed. The real trend, especially for our software vendor clients, is the move toward IoT electronic scales8. These are scales that don't just weigh an item but also communicate that data directly to the cloud or a company's ERP system. This technology is what we believe in, as it empowers our customers to revolutionize their operations and achieve real growth.

Conclusion

Ultimately, choosing the right scale comes down to your specific task, environment, and workflow. We are here to provide the expert advice you need to find that perfect fit.

-

Discover the unique features of bench scales and their ideal applications. ↩

-

Learn about various platform scales to find the best fit for your specific needs. ↩

-

Explore the differences to choose the right scale for your specific tasks. ↩

-

Find out how counting scales can streamline your inventory management process. ↩

-

Explore this resource to understand how scale capacity impacts your operations. ↩

-

Understand the critical role of durability in ensuring long-term scale performance. ↩

-

Explore this link to gain comprehensive insights into industrial scales and their applications. ↩

-

Explore how IoT scales can revolutionize your operations with real-time data. ↩

Comments (0)