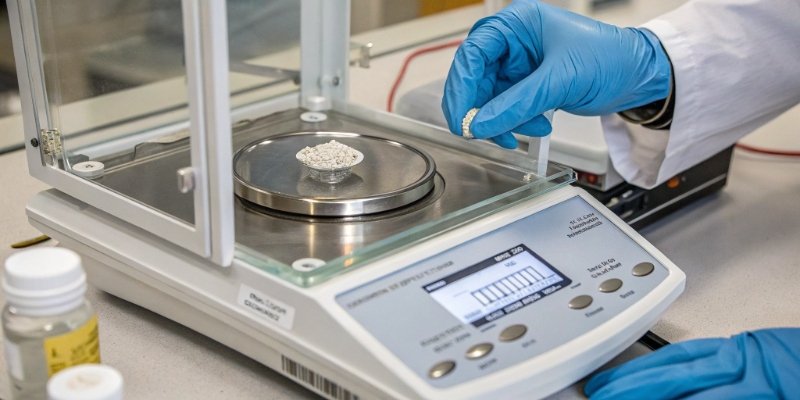

Feeling lost when looking at lab balances? Choosing the wrong one wastes time and money. Let’s break down the types to help you find the perfect match for your work.

Laboratory balances are mainly classified by their readability or precision. The four main types are precision, analytical, semi-micro, and micro balances. Balances can also be categorized by special functions, like moisture analyzers or counting scales, helping you get the right tool for your specific task.

Getting the right balance is crucial for good data. But knowing the names of the types is just the first step. The real key is understanding what makes each one different and which one is right for your lab. Let’s look closer at these differences. It will make your next purchase an easy one and ensure your results are always accurate.

What is the difference between an analytical balance and a precision balance?

Do analytical and precision balances seem the same to you? This common confusion can be a costly mistake, affecting both your budget and your results. Let’s clear up the confusion.

The main difference is readability. Analytical balances are more precise and can measure to 0.1 milligrams (0.0001g). Precision balances are less precise, typically measuring to 1 milligram (0.001g) or more. Analytical balances almost always have a draft shield for higher accuracy.

When we work with clients, this is one of the most common questions I get. Let’s dive deeper into what sets these two essential lab tools apart. I remember a client in the pharmaceutical industry who first bought precision balances1 for making their formulas. Their results were all over the place. After a quick call, we figured out they needed the higher readability2 of an analytical balance. Once they made the switch, their consistency issues disappeared. That small difference in the decimal place was everything for their quality control3.

Readability Defines the Job

The number of decimal places a balance can read is its single most important specification.

- Analytical Balances: These are the experts of the lab. With readability to four decimal places (0.0001g), they are perfect for chemical analysis, quantitative analysis, and formulation where the smallest amounts matter.

- Precision Balances: These are the workhorses. They offer good precision with readability to one, two, or three decimal places (0.1g to 0.001g). They are great for general weighing, sample preparation4, and quality control checks.

Application is Key

Thinking about the job you need to do makes the choice clear. The table below breaks down their common uses.

| Feature | Analytical Balance | Precision Balance |

|---|---|---|

| Readability | 0.0001g (0.1mg) | 0.001g – 1g |

| Common Use | Formulation, chemical analysis, density determination | Sample preparation, quality control, weighing larger amounts5 |

| Key Feature | High precision, always has a draft shield6 | Higher capacity7, more durable for general use |

The Draft Shield Factor

You will notice analytical balances8 have a glass or plastic box around the weighing pan. This is a draft shield. It’s not just for looks. It prevents air currents, dust, or even your breath from affecting the extremely sensitive measurement. Because precision balances weigh heavier samples and are less sensitive, they often don’t need one.

How do you choose the right type of lab balance for a specific application?

Need to buy a new lab balance but don’t know where to start? Making the wrong decision can set back your projects and your budget. I can give you a simple guide.

To choose the right balance, first figure out the readability you need based on your smallest sample. Next, check the capacity needed for your heaviest sample. Finally, consider the application itself, like quality control, formulation, or if you need special functions or certifications.

As a manufacturer of weighing equipment for 18 years, we don’t just sell a product; we provide a full solution. We guide our OEM and wholesale partners through these exact questions. Helping them serve their customers better is our goal. You need to think about a few key things to make sure the balance you pick is a perfect fit for your work.

1. Determine Your Required Readability

Start with the smallest amount of material you need to weigh accurately. The rule of thumb is that your balance’s readability should be at least one decimal place more precise than your required accuracy. For example, if you need to be accurate to the milligram (0.001g), you should use an analytical balance with a readability of 0.0001g. This gives you confidence in your measurements.

2. Assess Your Capacity Needs

Next, think about the heaviest item you will weigh. This includes the weight of your container, like a beaker or flask. This is a common mistake I see people make. They forget the container’s weight. The balance’s capacity must be higher than the total weight of your sample plus your container. Always choose a balance with a capacity a little higher than your maximum expected weight to be safe.

3. Consider Application and Other Features

Finally, what will you be doing every day?

- Special Functions: If you are checking the moisture content in food products, you need a moisture analyzer. If you are counting thousands of tiny electronic components, a parts counting scale will save you hours.

- Calibration: Balances can have internal or external calibration9. Internal calibration is automatic and convenient, saving time and reducing error. External calibration requires you to use certified weights manually. It’s cheaper but requires more work.

- Compliance: If you work in a regulated industry like pharma or food, you might need a balance that meets specific standards like GMP10 or GLP11.

What are microbalances and semi-microbalances used for?

Are your samples too small for even a standard analytical balance? Trying to weigh them on the wrong scale gives you useless data and can stop a project in its tracks.

Microbalances and semi-microbalances are used for applications that need the highest level of precision. They measure tiny samples in the microgram range. This is critical for particulate filter weighing, stent coating analysis, and checking pesticide residues, where accuracy is everything.

These are not your everyday lab balances. They are highly specialized instruments for high-stakes work. We once worked with an environmental testing lab that was failing its audits. Their analytical balances couldn’t reliably detect the tiny increase in weight on their air pollution filters. The data was not defensible. We provided them with microbalances, and their measurements became accurate and repeatable. They passed their next audit easily. It just shows how critical the right tool is when the measurements are that small.

The Ultimate Level of Precision

These balances take precision to the next level. The main difference between them is the readability.

- Semi-Microbalances: These offer readability to five decimal places (0.01mg). They bridge the gap between analytical balances and microbalances.

- Microbalances: These provide readability to six decimal places (0.001mg or 1µg). They are necessary when you are dealing with extremely small sample quantities.

- Ultra-Microbalances: For the most demanding applications, these balances read to seven decimal places (0.0001mg or 0.1µg).

This extreme precision means you need a very controlled environment. Vibrations, temperature changes, and air currents can all ruin a measurement. That’s why these balances have advanced draft shields and are often used on special anti-vibration tables.

Where They Are Found

You will find these balances in labs where the smallest detail matters.

- Environmental Science: Weighing tiny amounts of particulate matter collected on air filters.

- Medical Device Manufacturing: Measuring the drug coating on a coronary stent, where a few micrograms can affect patient outcomes.

- Pharmaceutical R&D: Accurately weighing expensive and potent active pharmaceutical ingredients (APIs).

- Materials Science: Analyzing coatings and thin films.

What do readability and capacity mean when classifying laboratory balances?

Do the terms "readability" and "capacity" on a balance spec sheet confuse you? Misunderstanding them is a common problem that leads to buying the wrong equipment. Let’s make them simple.

Readability is the smallest increment of mass a balance can display, like 0.001g. It defines the balance’s precision. Capacity is the maximum weight the balance can measure. You must consider both to ensure a balance meets your lab’s specific weighing requirements.

In my 18 years in the industrial weighing business, I find that a clear understanding of these two terms solves 90% of a customer’s problems when choosing a scale. They are the two most fundamental specifications of any balance, from the simplest shop scale to the most advanced ultra-microbalance. Getting them right is essential.

Readability is Your Precision

Readability is simply the smallest number a balance can show you. It’s the last digit on the display.

- A precision balance might have a readability of 0.01g.

- An analytical balance has a readability of 0.0001g.

- A microbalance has a readability of 0.000001g.

It is important to know that readability is not the same as accuracy, but it directly limits how accurately you can measure. You can’t be accurate to a milligram if your scale can only show you increments of 10 milligrams.

Capacity is Your Weight Limit

Capacity is easy. It is the heaviest weight the balance can handle before it shows an error message. But there is a common mistake here. When you place a container on the balance and press the "Tare" or "Zero" button, the display goes to zero. However, the weight of that container still counts toward the total capacity. If your balance has a 220g capacity and you use a 100g beaker, you only have 120g of capacity left for your sample.

The Readability vs. Capacity Trade-Off

Here is the most important part: you usually can’t have both extreme precision and very high capacity. They have an inverse relationship.

- High Readability (e.g., 0.0001g) = Lower Capacity (e.g., 120g – 220g)

- Lower Readability (e.g., 0.1g) = Higher Capacity (e.g., 2,000g – 8,000g)

I often see new buyers focus only on readability. They buy a great analytical balance but forget its capacity is only 220g. Then they try to weigh a 500g sample and don’t understand why the balance is giving an error. You must always consider both specs together to find the right tool for your specific job.

Conclusion

Choosing the right lab balance means matching its readability and capacity to your specific task. From precision to microbalances, the perfect tool ensures accurate, reliable results for your lab.

-

Learn about precision balances and how they can enhance your weighing accuracy in the lab. ↩

-

Get clarity on the concept of readability and its significance in choosing the right balance. ↩

-

Explore the role of balances in maintaining quality control standards in laboratory environments. ↩

-

Learn how balances are essential for accurate sample preparation in various applications. ↩

-

Find out which balances are suitable for weighing larger samples effectively. ↩

-

Discover why draft shields are essential for maintaining accuracy in sensitive measurements. ↩

-

Understand the importance of capacity in selecting a balance that meets your weighing needs. ↩

-

Discover the key differences between analytical and precision balances to make informed purchasing decisions. ↩

-

Explore the different calibration methods and their impact on balance accuracy. ↩

-

Learn about GMP compliance and its relevance in regulated industries. ↩

-

Discover the importance of GLP in ensuring quality and reliability in laboratory settings. ↩

Comments (0)