Are you confused by the wide range of truck scale prices? Choosing the wrong one can mean overspending or getting a scale that doesn't fit your needs. Let's fix that.

The final price of a truck scale primarily depends on its size, capacity, materials (steel or concrete), and type (pit or pitless). Additionally, extra features like unattended systems, software, and transportation and installation costs will significantly affect the total investment.

Buying a truck scale is a major decision for any business. The price tag can seem overwhelming at first. But once you understand what goes into it, you can make a much more informed choice. It's not just one thing; it's a combination of several key factors. We will look at each of these factors one by one. This will help you see where your money is going and allow you to choose a scale that perfectly matches your budget and operational needs1. Let's start breaking it down.

How Do Size and Capacity Affect the Price of Truck Scales?

Choosing the right size and capacity can be tricky. A scale that is too small for your trucks is useless. A scale that is way too big is a waste of money.

Simply put, larger scales and higher capacities cost more. A bigger scale deck requires more steel or concrete. Higher capacity demands more robust and therefore more expensive load cells to handle the weight accurately.

When we talk about the price of the scale itself, size and capacity2 are the two biggest drivers. First, let's look at size. The standard truck scale length is often around 18 meters, which fits most tractor-trailers. However, if you weigh vehicles with multiple trailers, you might need a longer scale, up to 30 meters or more. A wider scale might also be needed for easier vehicle access. The rule is simple: the more material needed to build the deck, the higher the price.

Second is capacity. This is determined by the load cells3, which are the sensors that measure the weight. A scale with a 60-ton capacity will have different load cells than one with a 100-ton capacity. Higher capacity load cells are engineered to be more robust and precise under extreme weight, which increases their cost. The number of load cells also plays a role. A longer scale will require more load cells to distribute the weight evenly, adding to the overall cost.

Here is a simple table to show the relationship.

| Factor | How It Affects Price | Common Choices |

|---|---|---|

| Size (Length) | Longer scales require more material, increasing the cost. | 18m, 21m, 24m |

| Size (Width) | Wider scales cost more due to extra material. | 3m, 3.2m, 3.4m |

| Capacity | Higher capacity needs stronger, more expensive load cells. | 60 tons, 80 tons, 100 tons, 120 tons |

What Material Considerations Impact the Cost of Truck Scales?

You will see options for steel deck and concrete deck scales. Picking the wrong one can lead to higher long-term costs or poor performance. Let's see how this choice helps you spend wisely.

Steel deck scales have a higher initial material cost but are faster to install and can be moved if needed. Concrete deck scales are cheaper upfront for materials but require on-site pouring and curing, adding to installation time.

The choice between a steel or concrete4 weighbridge deck is a classic trade-off between upfront cost and long-term considerations. From my 19 years of experience, a client's choice here often depends on their site and future plans.

A Steel Deck scale is built entirely at our factory and shipped to your site ready for installation. This makes installation very fast. You can often have it up and running in a day or two. This is a huge advantage if you need to minimize downtime. They are also considered portable. If you move your business, you can take the scale with you. The downside is that steel prices can be volatile, and the upfront cost is generally higher than for a concrete deck.

A Concrete Deck scale usually involves shipping a steel frame to your site. Then, you pour concrete into the frame. This makes the initial material cost5 lower. Concrete is also extremely durable and resistant to corrosion, especially in wet or corrosive environments. The main disadvantage is the installation time. The concrete needs to cure for several weeks before the scale can be calibrated and used, which can delay your operations.

| Feature | Steel Deck Scale | Concrete Deck Scale |

|---|---|---|

| Initial Cost | Higher | Lower |

| Installation | Fast (1-2 days) | Slow (requires weeks for concrete to cure) |

| Portability | Yes, can be relocated | No, permanent installation |

| Maintenance | Repainting may be needed to prevent rust | Very low, resistant to corrosion |

| Best For | Temporary sites, quick setup, relocatable needs | High-traffic, permanent, corrosive environments |

How Does the Type of Truck Scale Influence Its Pricing?

You need to decide between installing the scale in the ground or above the ground. This choice affects not just the price, but your site's entire workflow. Let's compare the two main types.

Pit-style scales cost more to install because they require significant excavation, foundation work, and drainage. Above-ground (pitless) scales are cheaper to install but need ramps for access, which adds cost and takes up more space.

The installation type is a major factor in the total cost of your truck scale project. The cost difference comes mostly from the civil works required for each type.

Pit-style scales are installed flush with the ground. This is great for sites with limited space because trucks can drive over them from any angle when they are not being used for weighing. It also provides a cleaner look. However, the costs here add up quickly. You have to pay for digging a large pit, building a concrete foundation, and, most importantly, installing a proper drainage system. If water collects in the pit, it can damage the load cells and electronics, leading to expensive repairs. Maintenance can also be harder because access to the components is restricted.

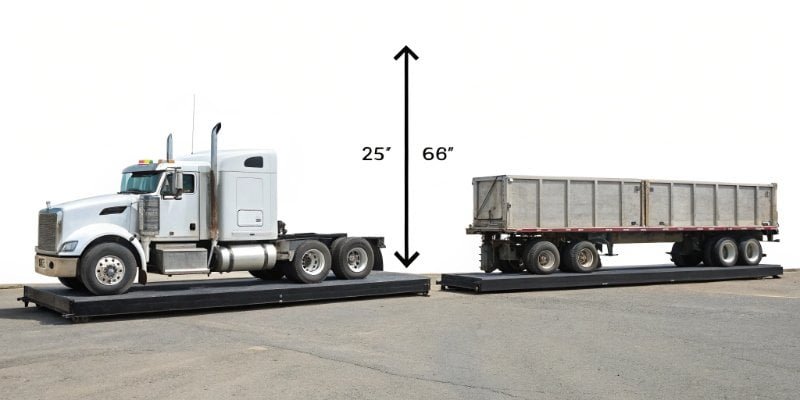

Pitless scales, or above-ground scales, are the more common choice. They are placed on a simple concrete slab. This makes the installation much cheaper and faster because you avoid major excavation. Access for cleaning and maintenance is also excellent. The main "cost" of a pitless scale is the space it occupies. You also have to purchase or build ramps for trucks to get on and off the scale. As an important note, these ramps can be a significant extra expense that you must factor into your budget.

| Factor | Pit-Style Scale | Pitless (Above-Ground) Scale |

|---|---|---|

| Installation Cost | High (due to excavation/drainage) | Lower (simple foundation slab) |

| Footprint | Smaller, blends into ground | Larger, requires space for scale and ramps |

| Maintenance Access | Difficult | Easy |

| Drainage Needs | Critical and complex | Minimal |

What Additional Features Can Alter the Price of Truck Scales?

A basic scale might get the job done, but maybe it isn't enough. You could miss out on big efficiency gains or end up paying for features you will never use. Let's look at common add-ons.

Features like unattended weighing systems, RFID readers, traffic lights, and advanced software can greatly increase the total price. A basic digital indicator is standard, but a fully automated system is a significant investment.

A truck scale is more than just a steel platform. The electronics and software that run it can range from very basic to highly advanced. A simple scale comes with a digital indicator that just shows the weight. This is the most affordable option. However, many businesses today want more automation and data integration.

One of the most expensive but valuable additions is an unattended weighing system. In my work, I've seen how these systems can completely change a company's operations. They allow drivers to weigh their trucks 24/7 without needing an operator. These systems typically include a kiosk with a touchscreen, an RFID card reader, a ticket printer, traffic lights6, and positioning sensors. While the initial cost is high, the return on investment from labor savings can be very fast.

Other features that add to the price include advanced weighing software that can manage data, create reports, and connect to your company’s ERP or accounting system. Peripherals like large remote displays7, guide rails8 for safety, and lightning protection systems9 also add to the final cost. Each feature adds a layer of efficiency and functionality, but it is important to decide which ones you truly need.

| Feature | Cost Impact | Benefit |

|---|---|---|

| Basic Indicator | Standard / Included | Displays weight only |

| Advanced Software | Moderate Increase | Data management, reporting10, ERP integration |

| Remote Display | Small Increase | Allows driver to see weight from the cab |

| Full Unattended System | Significant Increase | 24/7 operation without an attendant, major labor savings |

Conclusion

A truck scale's price is a mix of its size, capacity, material, type, and extra features. Knowing these factors helps you set a realistic budget and choose the best scale.

-

Understand how your specific operational needs can guide you in selecting the right truck scale. ↩

-

Explore how the size and capacity of truck scales can impact their pricing and suitability for your needs. ↩

-

Understanding load cells can help you appreciate their impact on the cost and performance of truck scales. ↩

-

Learn about the pros and cons of steel versus concrete truck scales to make the best choice for your business. ↩

-

Explore the cost implications of choosing between steel and concrete materials for truck scales. ↩

-

Discover how traffic lights can enhance safety and efficiency in truck scale operations. ↩

-

Explore how remote displays can improve user experience and operational efficiency at truck scales. ↩

-

Learn about the safety benefits of guide rails in truck scale installations. ↩

-

Discover the importance of lightning protection systems in safeguarding your truck scale investment. ↩

-

Understand the significance of reporting features in truck scale software for better decision-making. ↩

Comments (0)