Your production line needs perfect accuracy, but normal scales fail. This causes waste, quality issues, and profit loss. Industrial weighing technology provides the precision you need.

The most precise weighing technologies involve electromagnetic force compensation (EMFC) and advanced strain gauge load cells. EMFC is for ultra-fine measurements, while high-resolution strain gauge cells handle larger industrial loads with exceptional digital accuracy, ensuring reliability and minimal error for your critical processes.

Understanding the technology is one thing, but how does it translate to the actual scales you use every day? You might be wondering which specific type of scale will give you the best results for your unique application. Let's break down the different options available and find the right fit for your business needs.

Which type of weighing scale is most accurate?

Choosing the right scale from so many options is tough. The wrong choice leads to bad data and wasted investment. We can help you identify the most accurate scale type.

For ultimate precision, analytical balances using electromagnetic force compensation (EMFC) technology are the top choice. In most industrial environments, high-quality platform or bench scales equipped with digitally calibrated strain gauge load cells offer the most accurate and reliable performance for daily operations and process control.

The scale's accuracy comes from its core sensor technology. It's not just the digital display that matters.

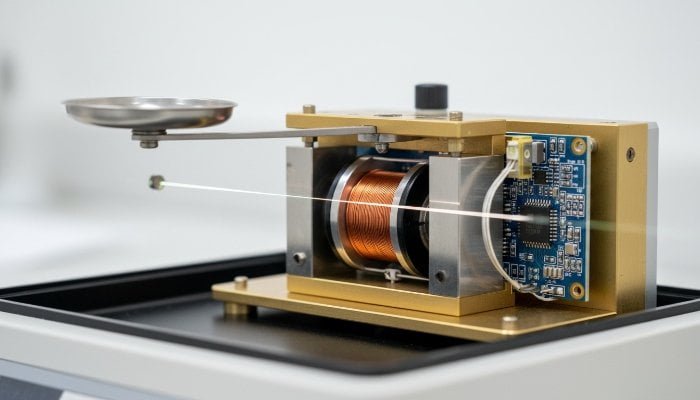

Electromagnetic Force Compensation (EMFC)1

This technology is the peak of precision. An electromagnet counteracts the weight on the scale. The electrical current needed to do this gives a direct, highly accurate weight measurement. This method is essential for laboratories and pharmaceutical applications where precision is critical.

Strain Gauge Load Cells

This technology is the workhorse of industrial weighing. It measures the physical strain or tiny deformation of a metal structure when a load is applied. While different from EMFC, modern industrial strain gauge cells are extremely accurate, durable, and cost-effective. We use industrial-grade steel2 and advanced digital calibration3 to ensure our scales deliver consistent results, even in tough factory environments. This robust design guarantees long-term reliability.

| Technology | Best For | Key Advantage |

|---|---|---|

| EMFC | Micro-weighing, Labs | Highest Precision |

| Strain Gauge | General Industrial Use | Durability & Value |

Which scale is the most precise?

People often confuse accuracy with precision. This mix-up can result in buying the wrong scale for your process. Understanding the difference ensures you get repeatable, reliable measurements every time.

The most precise scale is one that provides consistent, repeatable results. While analytical balances are the ultimate example, a high-quality industrial scale with a superior load cell and stable electronics delivers the high precision needed for consistent batching, filling, and quality control.

Many people use accuracy and precision to mean the same thing. In weighing, they are very different. Understanding this is key to selecting the right equipment for your success.

Accuracy vs. Precision: What’s the Difference?

Imagine you are shooting at a target.

- Accuracy means you are close to the bullseye. An accurate scale shows a weight that is close to the true, correct weight.

- Precision means your shots are all clustered together. A precise scale gives you the same result over and over again when weighing the same item.

Why Precision Matters in Industry

For industrial tasks like batching or filling, precision is often the priority. You need every bottle or bag to contain the exact same amount of product. This consistency comes from precision. Our scales deliver this with robust, industrial-grade mainboards and advanced software that ensures stable, repeatable readings. A basic scale might be accurate for a single weighment, but our industrial scales are built to be precise thousands of times a day. That's the difference.

How accurate are industrial weighing scales?

You need to trust your scale's data for quality control. But is a standard industrial scale accurate enough? Knowing about accuracy classes and certifications ensures your measurements meet all requirements.

The accuracy of an industrial scale is defined by international standards, like OIML classes. Typically, a high-quality industrial scale is accurate from 0.01% to 0.1% of its capacity. This means a 100kg capacity floor scale can be reliably accurate to as little as 10 grams.

A scale’s accuracy is not a vague promise. It's a certified specification. When you work with us, you get a performance guarantee based on strict international standards.

Understanding Accuracy Classes

Organizations like OIML set global standards for scale accuracy. Most industrial scales fall into Class III. This class defines the scale's resolution, or the number of "divisions" its capacity can be broken into. For a Class III scale with 3,000 divisions and a 150 kg capacity, the readability is 50g (150,000g / 3,000). The accuracy is guaranteed within a few of these divisions.

Build Quality and Testing

Certification is crucial, but real-world accuracy depends on build quality. We use industrial-grade steel with special anti-rust and anti-corrosion treatments. This prevents flexing or degradation that can ruin accuracy. Before shipping, our quality inspection department tests every single product. We verify weight accuracy, battery performance, and software function. A scale only leaves our factory after it passes these rigorous tests.

What is industrial weighing?

The term "industrial weighing" can be confusing. You might think it just means bigger scales, overlooking the real advantages. It’s actually about creating a durable, efficient, and integrated weighing system.

Industrial weighing is the application of robust, precise scales in production and logistics. Unlike simply measuring weight, it involves process control, data integration with IoT systems, and automation. These systems are built to endure harsh industrial environments and improve efficiency.

Industrial weighing is completely different from weighing things in a store. It is a critical part of a production or logistics process. I've spent my career helping businesses see this vital difference.

More Than Just a Scale

It is about creating a full system. As a software vendor, you know the power of data. Our scales are designed to connect with your software to enable functions like:

- Automation: Automatically stopping a conveyor when a target weight is met.

- Data Logging: Recording every measurement for quality control records4.

- IoT Integration: Transmitting live weight data to your dashboards.

Built for Your Environment

An industrial scale must survive its workplace. This requires using industrial-grade mainboards, steel with anti-rust treatments, and enclosures that are protected against dust and water. This is why industrial scales are a bigger investment than commercial ones. You are paying for durability, reliability, and process uptime, not just a number on a screen.

Conclusion

Choosing the right industrial scale means balancing precision technology with durable construction. This ensures you get the accurate, repeatable, and integrated data your modern industrial process requires for success.

-

Explore how EMFC technology enhances precision in weighing, crucial for labs and industries. ↩

-

Discover why industrial-grade steel is essential for durability and accuracy in weighing scales. ↩

-

Learn how digital calibration enhances the accuracy and reliability of weighing scales. ↩

-

Find out how quality control records are essential for ensuring product consistency. ↩

Comments (0)