Working in hazardous areas risks explosions. A normal scale could be the trigger. You must use explosion-proof scales that meet strict safety requirements to ensure safety.

Explosion-proof scales must have high dust protection and prevent any electrical sparks. The specific requirements depend on the hazardous area classification (Zone 0/20, 1/21, 2/22), which defines the level and frequency of explosive materials present. Each zone demands a different level of equipment protection.

Understanding these requirements is critical. It's not just about buying a scale labeled "explosion-proof." It's about matching the right scale to the right hazardous zone. Over my 19 years in this industry, I've seen how a mismatch can lead to serious safety failures1. Let's break down exactly what you need to look for, starting with the basic principles of explosion-proofing. This knowledge will help you make the right choice and protect your operations.

What are the requirements for explosion proof?

What does "explosion-proof" really mean for a scale? Choosing incorrectly is a huge safety gamble. The key requirements involve preventing ignition through intrinsic safety or robust explosion-proof enclosures.

The main requirement is to prevent the scale from igniting a surrounding explosive atmosphere. This is achieved by either limiting the electrical energy to levels too low to cause a spark (intrinsic safety) or containing any potential explosion within a rugged enclosure that can withstand the pressure.

In my experience, the term "explosion-proof" covers a few different protection concepts. The goal is always the same: prevent the equipment from becoming an ignition source. We achieve this mainly through two distinct methods that align with our core design principles of high dust protection and preventing any electrical sparks.

Intrinsic Safety (IS)

This is a proactive approach. We design the electrical circuits so they have very low energy. The voltage and current are limited to a point where they are physically incapable of creating a spark hot enough to ignite a flammable gas or dust cloud. This is a very common method for modern scales, especially those that need to connect to other systems, like your software. It is a system-level approach that requires careful integration to maintain the safety barrier.

Explosion-Proof/Flameproof Enclosures

This is a reactive approach. The enclosure is built to contain an internal explosion. If a spark inside the equipment ignites a gas that has seeped in, the housing is strong enough to withstand the pressure and prevent the flame from escaping. This method demands extremely strict structural design and manufacturing. Our production process focuses heavily on the integrity of these enclosures, ensuring they are perfectly sealed and incredibly strong to meet certification standards.

Here is a simple comparison:

| Protection Method | Principle | Best For |

|---|---|---|

| Intrinsic Safety (IS) | Limit energy to prevent sparks | Zones 0/20, 1/21; integrating with systems |

| Explosion-Proof Enclosure | Contain any internal explosion | Zones 1/21, 2/22; heavy-duty applications |

Choosing correctly depends entirely on your specific zone and operational needs. For software vendors like you, understanding that an IS scale is designed for low-power, safe data transfer is key.

What are the 3 grade of explosion protection inspections?

You see a certification label, but what do the codes mean? Misreading them could lead to installing an unsafe scale and failing inspections. Understanding Equipment Protection Levels (EPLs) is essential.

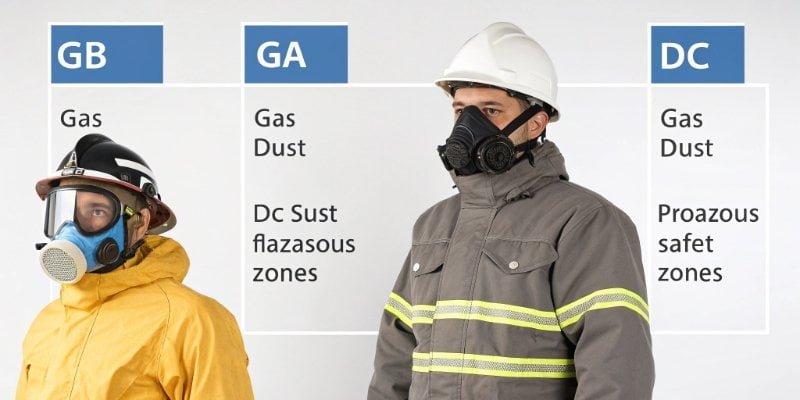

There are three main Equipment Protection Levels (EPLs). For gas: Ga (Zone 0), Gb (Zone 1), and Gc (Zone 2). For dust: Da (Zone 20), Db (Zone 21), and Dc (Zone 22). Each level signifies the equipment is safe for its corresponding hazardous zone.

The "grades" you are asking about are technically called Equipment Protection Levels, or EPLs. They tell you exactly how safe a piece of equipment is and where it can be used. Think of it as a safety rating. At Weigherps, our quality control department meticulously tests every unit to ensure it meets its designated EPL before it ever leaves our factory. The levels are divided based on whether the hazard is gas or dust.

Protection Levels for Gas Atmospheres (G)

These are designated with a "G" and relate to the risk from flammable gases, vapors, or mists.

- Ga: Very high level of protection. The equipment is safe even if two independent faults occur. This level is required for the most dangerous areas, Zone 02.

- Gb: High level of protection. The equipment is safe during normal operation and with expected faults. This is the standard for Zone 13.

- Gc: Normal level of protection. The equipment is safe only during normal operation. This is suitable for Zone 24.

Protection Levels for Dust Atmospheres (D)

These are designated with a "D" and are for environments with combustible dust5.

- Da: Very high protection. This is for areas with a constant dust hazard, Zone 206.

- Db: High protection. This is required for areas where dust clouds are likely during normal work, Zone 217.

- Dc: Normal protection. This is for areas where dust clouds are unlikely, known as Zone 228.

Here is a summary table:

| EPL | Hazard | Corresponding Zone | Level of Protection |

|---|---|---|---|

| Ga | Gas | Zone 0 | Very High |

| Gb | Gas | Zone 1 | High |

| Gc | Gas | Zone 2 | Normal |

| Da | Dust | Zone 20 | Very High |

| Db | Dust | Zone 21 | High |

| Dc | Dust | Zone 22 | Normal |

Matching the EPL to your zone is a non-negotiable step in ensuring safety and passing any inspection.

What are the three classification of hazardous areas?

Terms like "Zone 0" and "Zone 21" can be confusing. Guessing your area's classification is dangerous and impacts the equipment you need. The zones simply define how often hazards exist.

Hazardous areas are classified by zones based on the frequency and duration of an explosive atmosphere. For gases, they are Zone 0 (continuous hazard), Zone 1 (likely hazard), and Zone 2 (unlikely hazard). For dusts, the equivalent zones are Zone 20, Zone 21, and Zone 22.

Before you can even think about a scale, you must know your area's classification. This classification is all about risk, specifically the likelihood of an explosive atmosphere being present. The system is split for gases and dusts. I have worked with clients across many industries, and getting this classification right is the most critical first step. An expert risk assessment9 is needed to officially define your zones.

Gas, Vapor, and Mist Zones

This classification is used for airborne flammable substances that are not solid particles.

- Zone 0: An area where an explosive gas atmosphere is present continuously, for long periods, or frequently. Think of the inside of a closed fuel tank or chemical reactor.

- Zone 1: An area where an explosive gas atmosphere is likely to occur in normal operation. For example, the area right around a valve where flammable liquid is dispensed or a sampling point.

- Zone 2: An area where an explosive gas atmosphere is not likely to occur in normal operation, and if it does, it will only exist for a short period. This could be a storage room where flammable liquids are kept in sealed containers.

Combustible Dust Zones

Dust from materials like grain, sugar, flour, metal, or chemicals can be just as explosive as gas.

- Zone 20: An area where a cloud of combustible dust is present continuously or frequently. For example, inside a silo, processing vessel, or a pneumatic conveyor system.

- Zone 21: An area where a combustible dust cloud is likely to occur in normal operation, such as near bagging points or where dust can accumulate and be disturbed.

- Zone 22: An area where a dust cloud is not likely to occur in normal operation. If it does, it is only for a short time. For instance, a storage area where dusty products are kept in well-sealed bags could be a Zone 22.

What is hazardous area classification explosion proof?

We've covered zones, levels, and protection types. But how does it all connect? It can seem complex, and a mistake is not an option. It's a simple framework for matching equipment to a risk.

It is a systematic process. First, you identify hazardous zones (e.g., Zone 1, Zone 21) based on risk. Then, you select equipment with the corresponding protection level (e.g., EPL Gb, EPL Db) and protection type (e.g., Intrinsic Safety) certified for that zone.

Let's put everything together. Hazardous area classification for explosion-proof equipment is a logical workflow. It's how we, as manufacturers, and you, as a user, ensure the right tool is used for the right job. As a software provider, understanding this process helps you specify hardware that will integrate seamlessly and safely with your systems.

The process is straightforward:

Step 1: Classify Your Area

First, an expert must assess your facility to determine the zones. Is it Zone 1 because of flammable vapors? Or Zone 22 due to occasional combustible dust? This assessment is the foundation of your entire safety plan10.

Step 2: Match the Zone to the EPL

Once you know the zone, the required Equipment Protection Level (EPL) is clear. You cannot put a Zone 2 (EPL Gc) rated scale in a Zone 1 area. The risk is too high, and it would fail any safety audit11. You must choose equipment with an EPL rated for that zone or a safer one (e.g., a Zone 1 scale can be used in Zone 2).

Step 3: Choose the Right Scale

Finally, you select a scale that has the right EPL certification and uses a protection method suitable for your operation. Here is how the pieces fit together in practice:

| Your Area's Situation | Step 1: Zone | Step 2: Required EPL | Step 3: Example Scale Required |

|---|---|---|---|

| Flammable gas is likely present | Zone 1 | Gb | Scale with Intrinsically Safe (IS) or Flameproof protection |

| Combustible dust is constantly present | Zone 20 | Da | Scale with Intrinsically Safe (IS) protection |

| Gas is only present in a fault condition | Zone 2 | Gc | Scale with Type "n" non-sparking protection |

We have been providing these targeted solutions for 19 years, helping clients navigate this process to find the most cost-effective and safe weighing equipment12 for their exact needs.

Conclusion

Correctly classifying your hazardous zone and matching it with the right certified explosion-proof scale is essential. This crucial step guarantees safety, compliance, and protects your entire operation.

- Learn about common safety failures to avoid costly mistakes and ensure compliance in hazardous environments. ↩

- Understanding Zone 0 is essential for safety; this link provides insights into its characteristics and requirements. ↩

- Explore the specific safety requirements for Zone 1 to ensure compliance and protect your operations. ↩

- Learn about Zone 2 and its implications for equipment selection and safety in hazardous environments. ↩

- Explore the dangers of combustible dust to understand the importance of safety measures in industrial environments. ↩

- This resource clarifies the meaning of Zone 20, helping you understand safety requirements for dust hazards. ↩

- Explore the risks of Zone 21 to ensure your equipment meets safety standards for this classification. ↩

- Understanding Zone 22 is crucial for safety; this link explains its characteristics and equipment requirements. ↩

- This guide provides steps for conducting a risk assessment, essential for ensuring safety in hazardous zones. ↩

- This resource offers guidance on creating a safety plan tailored for hazardous environments. ↩

- Learn what a safety audit entails to ensure compliance and safety in hazardous work environments. ↩

- Explore top weighing equipment options designed for safety in hazardous environments. ↩

Comments (0)