Your scale failing from water damage is a costly problem. This disrupts production, causes downtime, and hurts your bottom line, forcing you to constantly replace expensive equipment.

Typical waterproof ratings for industrial scales range from IP65 for dust and water jet protection to IP68 for complete, continuous submersion. The best rating depends on your work environment, from light washdowns to harsh, wet conditions, ensuring the scale's longevity and accuracy.

These ratings are more than just numbers on a spec sheet. They are a promise of reliability. When you see an IP rating, it tells you exactly what kind of environment the scale is built to withstand. As a manufacturer for 19 years, I've seen firsthand how matching the right rating to the right job is the key to a long-lasting, accurate weighing system. But to make that match, you first need to understand what these ratings actually mean and how they are determined. Let's dive into the specifics so you can choose with confidence.

How Are Waterproof Ratings Determined for Industrial Scales?

You see IP ratings on many devices, but the numbers can be confusing. Choosing the wrong one based on a guess can be a costly mistake for your operations.

Waterproof ratings are defined by the Ingress Protection (IP) code, an international standard. The first digit (0-6) measures protection against solids like dust, while the second digit (0-9) measures protection against liquids like water. Rigorous, standardized tests determine these numbers.

At our factory, we take these tests very seriously. It’s not a matter of just splashing some water on the scale. The IP code system is precise, and the tests must be just as precise to be valid. For a scale to earn its rating, it undergoes a series of controlled procedures in our dedicated testing facility1. These tests simulate real-world conditions, from fine dust exposure to high-pressure water jets2 and even complete submersion for extended periods.

Understanding the Digits

The process is methodical. The second digit, which is crucial for waterproofing, has a clear meaning tied to a specific test. For example, a "5" is very different from a "7".

| Second Digit | Protection Against Water | Test Details |

|---|---|---|

| 5 | Water jets | Water projected by a nozzle from any direction. |

| 6 | Powerful water jets | Powerful jets of water from any direction. |

| 7 | Temporary immersion | Immersion in water up to 1 meter for 30 mins. |

| 8 | Continuous immersion | Immersion beyond 1 meter (depth specified by us). |

This certified process ensures that when you choose a Weigherps scale, its IP rating is a guarantee of performance you can trust.

What Are Common IP Ratings for Industrial Scale Water Resistance?

You need a waterproof scale, but the range of options can feel overwhelming. Picking a rating that's too low leads to failure; picking one that's too high means you've overspent.

The most common ratings you'll encounter are IP65, ideal for general dust and light washdowns. IP67 is for environments requiring temporary submersion, and IP68 is for continuous submersion in harsh conditions. Matching the rating to your cleaning protocol is essential.

Choosing the right IP rating is all about understanding your daily operations. A scale in a dry warehouse that only needs an occasional wipe-down has very different needs from a scale on a food processing line that gets a high-pressure chemical wash every day. Over my years in the industry, I've seen many clients extend the life of their equipment simply by upgrading to the correct IP rating. It's not about getting the highest number; it's about getting the right number for the job.

Matching the Rating to the Environment

To simplify your choice, let's break down where each common rating excels. Think about your application and find the best fit.

| IP Rating | Protection Level | Typical Industrial Application |

|---|---|---|

| IP65 | Low-pressure water jets | Dusty environments (e.g., workshops) with light cleaning or spray. |

| IP66 | High-pressure water jets | Areas with heavy washdown procedures, like food production. |

| IP67 | Temporary submersion | Environments where accidental drops into tanks or bins may occur. |

| IP68 | Continuous submersion | Seafood industry, underwater weighing, extremely wet environments. |

I once worked with a seafood company that was replacing its scales every six months. We analyzed their process and realized their IP65 scales were no match for the constant water exposure and sanitation. We equipped them with a custom IP68 solution, and their scales have been running without issue for years. It proves that the initial investment in the correct protection pays for itself many times over.

How Do Waterproof Ratings Affect the Performance of Industrial Scales?

An IP rating might seem like just a durability feature for your scale. But moisture doesn't just break a scale; it quietly causes inaccurate readings long before total failure occurs.

A proper waterproof rating directly protects a scale's long-term accuracy and reliability. By sealing sensitive internal components like load cells and electronics from moisture and corrosion, it prevents signal drift, inaccurate measurements, and expensive operational errors.

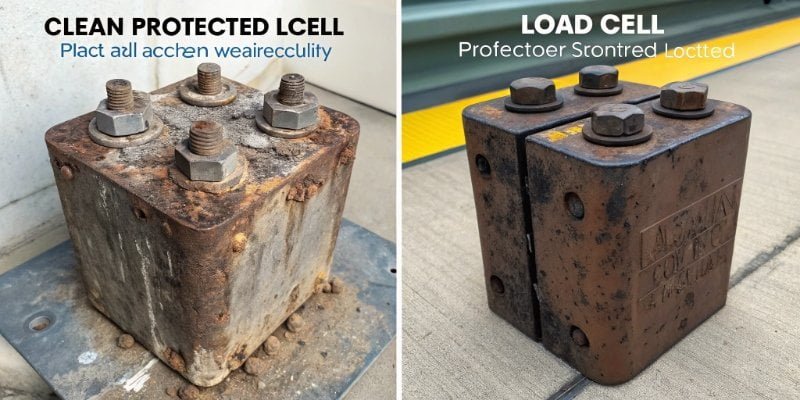

The real danger of an inadequate waterproof rating isn't always a sudden, catastrophic failure. The more common issue is a slow, silent decline in performance. When moisture seeps into the housing, it begins to corrode the delicate electronics and, most importantly, the load cell—the heart of the scale. This corrosion3 introduces errors into the weight readings. Your scale might still turn on and appear to function, but it's no longer providing the correct data. This can lead to giving away products for free, failing compliance checks, or producing inconsistent batches.

The Link Between Protection and Precision

Accuracy is everything in industrial weighing. An unprotected or under-protected scale is a liability. The moisture that gets inside can create small electrical shorts or degrade the strain gauges within the load cell, causing the zero point to drift or the weighted measurements to become unstable. You might start seeing fluctuating numbers or find yourself constantly recalibrating the scale, which are classic signs of internal moisture damage.

This is why our quality control department is so rigorous. Every product we ship undergoes comprehensive testing. We inspect every seal, gasket, and cable gland to ensure they meet the IP standard. We don't just test if a scale survives contact with water; we test if its accuracy remains perfect after exposure. This commitment to precision ensures your operation runs smoothly and profitably.

What Should You Consider in Terms of Waterproofing When Choosing an Industrial Scale?

Choosing a new scale involves many factors, and waterproofing can be an easy detail to overlook. Neglecting this can lead you to buy a scale that's completely unfit for your real-world work environment.

Consider your daily cleaning methods, the presence of corrosive chemicals, and any risk of submersion. Also, evaluate the scale's housing material, like 304 or 316 stainless steel, which works with the waterproof rating to provide complete environmental protection.

The core idea from my insight is that we can tailor a solution for you. We just need to understand your world. When a client comes to us, we don't just point them to a catalog. We start a conversation. I ask them to walk me through their day. How do they clean their equipment? What chemicals do they use? Is the scale near a tank where it could fall in? This discussion is the most important step in the buying process. It helps us move beyond standard options and engineer a weighing solution4 that truly fits.

A Practical Checklist for Your Purchase

Think through these questions before you make a decision. Your answers will point you directly to the right scale.

- Cleaning Method: Do you wipe the scale down, rinse it with a low-pressure hose, or blast it with high-pressure, high-temperature jets5? This is the primary factor in deciding between IP65, IP66, and IP67.

- Chemical Exposure: Will the scale come into contact with simple water, or will it be exposed to salts, acids, or harsh cleaning agents? This will determine if you need a standard housing or a more corrosion-resistant material like 316 stainless steel6.

- Submersion Risk: Is there any chance the scale could be temporarily or permanently submerged in liquid? If so, IP67 or IP68 is non-negotiable.

- Total Cost of Ownership: Is it more cost-effective to invest in a higher-rated, durable scale now, or to plan for replacing a cheaper, less-protected scale in a year or two?

As a manufacturer, our strength lies in our flexibility. Once we have your answers, our production team can get to work creating a scale that meets your exact specifications. Your environment is unique, and your scale should be too.

Conclusion

Understanding waterproof ratings is key to choosing a durable and accurate scale. By matching the IP rating to your environment, you ensure long-term reliability and protect your investment.

- Get insights into the rigorous testing processes for waterproof ratings. ↩

- Learn about the applications and effects of high-pressure water jets in industry. ↩

- Understand the impact of corrosion on scale performance and longevity. ↩

- Discover key considerations for creating tailored weighing solutions. ↩

- Explore the role of high-temperature jets in industrial cleaning applications. ↩

- Learn about the differences and applications of 304 vs 316 stainless steel. ↩

Comments (0)