Are you tired of manual data entry errors and slow, inefficient weighing processes? This creates mistakes that cost you time and money, impacting your entire production and inventory management.

Intelligent weighing scale software connects your industrial scales to a computer or network. It automates the collection, processing, and management of weight data, turning a simple scale into a smart data hub for your business. This eliminates manual errors and provides real-time operational insights.

That’s the short answer. But the real power of this software lies in the details of how it operates and the specific ways it can transform your workflow. In my 19 years of manufacturing industrial scales, I’ve seen firsthand how applying a computer operating system and a dedicated software layer is the defining mark of modern, efficient production. It’s the virtual force that drives automation. To truly grasp its value, we need to dive deeper into how it functions and what advantages it brings.

How Does Intelligent Weighing Scale Software Function?

Is your team still writing down weights manually? This gap between weighing an item and recording the data is a huge source of errors and slows down your entire operation.

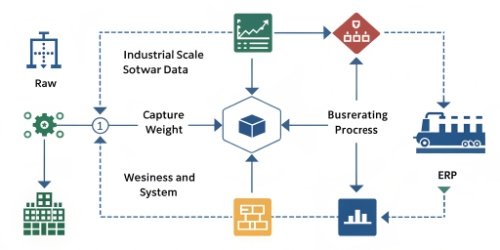

The software functions by establishing a direct communication link with the scale, often via RS232 or a network connection. It captures the raw weight data automatically, processes it according to pre-set rules, and then integrates it with business systems like your ERP or WMS.

Dive Deeper: The Three-Step Process

The magic of intelligent software happens in a seamless, three-step flow. It’s a process we’ve perfected over years of developing custom weighing solutions for our clients. It's not just about getting a number from point A to B; it's about adding intelligence at every step.

1. Data Capture

The process begins the moment an item is placed on the scale. The scale's digital indicator generates a weight value. The software, running on a nearby PC or a central server, is constantly "listening" for this signal. It connects to the scale using a specific communication protocol. This connection can be a physical cable (like a traditional RS232 serial port or a modern USB) or a network connection (like Ethernet or Wi-Fi). This direct capture ensures the number recorded is the exact number shown on the scale display, with no chance for human error.

2. Data Processing and Enrichment

Once the raw weight is captured, the software gives it context. This is where it becomes more than just a number. For example, a worker can scan a barcode, and the software instantly associates the weight with a specific product, batch number, or customer order. It can automatically subtract the container's weight (tare), check if the weight is within an acceptable tolerance, and add a timestamp and operator ID. This enriched data point is far more valuable for traceability and quality control.

3. System Integration

Finally, the enriched data is put to work. The software sends the complete data package to your other business systems.

| System Receiving Data | Action Performed | Business Impact |

|---|---|---|

| ERP System | Updates inventory levels in real-time. | Accurate stock counts, prevents stockouts or over-ordering. |

| WMS (Warehouse Mgt. System) | Logs received goods or prepared shipments. | Faster order fulfillment and receiving processes. |

| Quality Control Database | Records pass/fail results for SPC analysis. | Identifies production trends and improves product quality. |

| Label Printer | Generates a shipping or product label. | Automates labeling, ensuring accuracy and speed. |

This integration turns the weighing station into an active part of your overall business intelligence network1.

What Are the Key Features of Smart Weighing Scale Software?

Is your current weighing system just a simple scale that only shows weight? This means you are missing out on automation opportunities and valuable data that could streamline your operations.

Key features include real-time data acquisition from multiple scales, barcode and RFID scanning for quick product identification, user management for accountability, detailed report generation for analysis, and direct integration with existing ERP and WMS systems to ensure seamless data flow across your company.

Dive Deeper: Features That Drive Value

When we talk to software vendors and technical directors, they want to know what a system can do. It's not enough for it to just work; it has to provide tangible tools that solve real-world problems. Over the years, we have built our software solutions around a core set of features that our clients depend on. These are the tools that truly define "intelligent" weighing.

Core Functionality

These are the foundational features that every good weighing software should have. They handle the basic tasks of data collection and management with precision. This includes capturing weight in real-time, managing tare weights (both manual and pre-set), and logging every single transaction with a timestamp. This creates a simple but powerful audit trail that is the first step towards full traceability.

Advanced Capabilities

This is where the software starts to get really smart. We integrate features that automate complex tasks. For instance, Barcode/RFID Integration allows an operator to simply scan a product, and the software instantly pulls up all the relevant information, like target weight and product name. Formula Management is critical for industries like chemicals or food production, where the software guides the operator to add precise amounts of different ingredients to create a batch. Statistical Process Control (SPC)2 features monitor weights over time to flag potential issues before they become major problems.

Connectivity and Reporting

The most powerful feature is the software's ability to communicate. As a manufacturer focused on providing holistic solutions, we know that a scale can't be an island.

| Feature Group | Specific Tools | Primary Benefit for Your Business |

|---|---|---|

| Connectivity | Direct API or database connections (SQL, Oracle). | Breaks down data silos, creating a single source of truth. |

| Reporting | Customizable report templates, export to Excel/PDF. | Turns raw data into actionable insights for managers. |

| User Management | Role-based access control, operator logins. | Enhances security and provides clear accountability. |

These features work together to create a system that is not only automated but also secure, accountable, and rich with data.

How Does Intelligent Software Improve the Accuracy and Efficiency of Weighing Scales?

Do you still rely on people to write down weights? Even with the most precise scale, a simple slip of the pen or a typing mistake can throw your entire inventory into chaos.

Software boosts accuracy by completely eliminating manual data entry. It captures the exact digital signal from the scale. Efficiency is improved by automating repetitive tasks like logging and labeling, which dramatically reduces the time it takes to complete each weighing cycle.

Dive Deeper: The Twin Pillars of Improvement

When we implement a weighing system for a client, their two biggest goals are almost always the same: improve accuracy and increase efficiency. These are not just buzzwords; they represent real, measurable improvements to the bottom line. Intelligent software is the single most effective tool for achieving both. Let's break down how.

Boosting Measurement Accuracy

The weakest link in any manual weighing process is the human. We get distracted, we transpose numbers, and we make mistakes. Software removes this variable.

- Eliminates Transcription Errors: The weight displayed on the scale's indicator is the exact weight that gets saved in the database. There is no opportunity for a "fat finger" error or for someone to misread the display.

- Enforces Standard Procedures: The software can be configured to guide the operator through a required sequence. For example, it might not allow a weight to be recorded until a container has been tared or a product barcode has been scanned. This ensures consistency and prevents procedural shortcuts that lead to bad data.

Increasing Operational Efficiency

In any industrial setting, time is money. Shaving seconds off a repetitive process can add up to huge labor savings over a year.

- Reduces Manual Labor: Think about all the steps involved in a manual weigh: place item, wait for stable weight, write it down, move the item, and later, enter that data into a spreadsheet. Software reduces this to one step: place the item and scan it. The rest is automatic.

- Accelerates the Entire Workflow: The difference between a manual process and an automated one can be dramatic.

| Task | Manual Method | Software-Assisted Method | Time Saved per Transaction |

|---|---|---|---|

| Data Logging | Write on a log sheet. | Automatic capture. | 10-15 seconds |

| Labeling | Write label by hand. | Auto-print on scan. | 15-20 seconds |

| Reporting | Manually compile data. | Instant report generation. | Hours |

For a company processing hundreds or thousands of items a day, these seconds add up to full-time employees' worth of saved labor.

What Are the Operational Advantages of Using Intelligent Weighing Scale Software?

Are your production, inventory, and quality control departments working from different sets of data? These information silos make it impossible to get a clear view of your operations and react to problems fast.

Operational advantages include total product traceability for compliance, enhanced quality control through automated tolerance checks, and precise inventory management. It also provides a rich source of data for making informed business decisions and significantly reduces operational costs by cutting labor and waste.

Dive Deeper: From Data to Decisions

The ultimate goal of any technology investment is to improve the business. Intelligent weighing software does this by providing clear, tangible operational advantages3 that go far beyond just weighing things. It transforms the weighing station from a simple measurement point into a strategic data source that fuels business growth. As a weighing expert, I always tell my clients to think about the big-picture benefits.

Unbreakable Traceability

In today's world, especially in industries like food, pharmaceuticals, and chemicals, traceability is non-negotiable. Software creates an unbreakable digital chain. I remember a client in the food processing industry who faced a potential recall. With their new system, they could pinpoint the exact batch, the time it was weighed, and the operator who handled it, all within minutes. Before, this would have taken days of digging through paper logs, forcing a much larger and more expensive recall. This capability is not just for protection; it’s a mark of quality that builds trust with your customers.

Data-Driven Process Optimization

Gut feelings are not a reliable way to run a factory. Software provides hard data. Managers can pull reports to see which production lines are the most efficient, where material loss is highest, or if a particular weighing station is consistently producing out-of-spec products. This allows them to make targeted improvements based on facts, not guesswork.

Significant Cost Reduction

Finally, it all comes down to the bottom line. The operational advantages all contribute to reducing costs and increasing profits.

| Advantage | How It Reduces Costs |

|---|---|

| Reduced Labor | Automating tasks means you can reallocate staff to more valuable work. |

| Minimized Waste | Precise formula control and tolerance checks reduce scrapped batches and material giveaway. |

| Lower Compliance Risk | Having a perfect audit trail reduces the risk of fines and costly recalls. |

| Accurate Inventory | Prevents the cost of holding excess stock or a production stoppage due to lack of materials. |

By connecting your scales to your business systems, you are empowering your entire operation to be smarter, faster, and more profitable.

Conclusion

Ultimately, intelligent weighing software is the crucial bridge between your physical hardware and your digital data. It automates key processes, guarantees accuracy, and unlocks the insights you need for modern industrial operations.

Comments (0)