You need to measure weight or force, but the technology seems complex. Inaccurate measurements can cause product waste and compliance issues, hurting your bottom line. Understanding the load cell is key.

A load cell is a force sensor, or transducer. It converts a mechanical force, like weight or pressure, into a measurable electrical signal. This core component is the heart of modern digital scales and weighing systems, enabling precision across many industries.

I’ve spent 18 years in the industrial weighing1 business, and if there's one component that defines everything we do, it's the load cell2. It’s the unsung hero of modern industry. You find it everywhere from the checkout counter at a grocery store to massive silos weighing hundreds of tons. It’s the crucial link between the physical world of force and the digital world of data that your software and control systems rely on. Without it, automation3 and quality control would be impossible. Let’s break down what this device is, how it works, and why it's so important for your business.

What is the purpose of a load cell?

You see weighing systems everywhere, but do you know why they are so critical for business? Without them, quality control becomes guesswork, and efficient automation grinds to a halt.

The main purpose of a load cell is to provide the accurate and repeatable data that drives modern industry. It enables precision weighing for everything from process control and quality assurance to safety monitoring and commercial transactions.

At its heart, a load cell serves one primary function: it translates physical force into a language that computers can understand. This data conversion4 is the foundation of countless industrial processes. For my clients, especially software vendors creating IoT solutions, this clean, reliable data is everything. They build their entire systems around the numbers our load cells provide. The applications are incredibly diverse, and each one relies on this core purpose.

The Core Function: Data Conversion

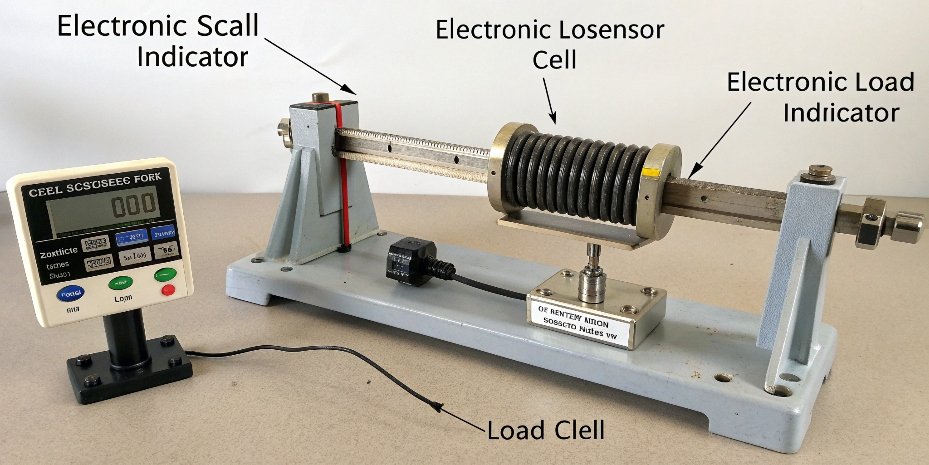

A load cell acts as a bridge between the physical and digital worlds. When a force is applied, the load cell deforms slightly. This tiny change alters an electrical signal5, which is then sent to a digital indicator or a computer. This indicator interprets the signal and displays it as a weight measurement, like kilograms or pounds. It's a simple concept, but getting it right requires precise engineering.

Applications Across Industries

The value of this data conversion is clear when you look at how different industries use load cells. From our experience at Weigherps, we've implemented solutions for a massive range of uses.

| Industry | Application | Key Benefit |

|---|---|---|

| Manufacturing | Batching ingredients, mixing formulas | Product consistency and quality control |

| Logistics & Shipping | Weighing packages and freight | Accurate billing and load optimization |

| Agriculture | Silo and hopper weighing | Inventory management and feed control |

| Construction | Crane load monitoring | Overload prevention and operational safety |

Each of these applications depends on the load cell to provide trustworthy data that informs critical business decisions, improves efficiency, and ensures safety.

What are the four main types of load cells?

Choosing the right component for a project can be confusing. The wrong choice can lead to inaccurate data, system failure, and wasted investment. Understanding the main types makes it simple.

The most common type is the strain gauge load cell, which offers high accuracy. Other key types include hydraulic, pneumatic, and piezoelectric load cells. Each uses a different principle to measure force and is suited for specific environments or applications.

When a client comes to me with a new project, one of the first questions we discuss is the type of load cell they need. The operating environment, the capacity, and the type of force being measured all influence this decision. While there are several niche technologies, most industrial applications rely on one of four main types. Over the years, I've seen each one used to solve unique challenges, but one type stands out as the most versatile.

The Workhorse: Strain Gauge Load Cells

The vast majority of electronic scales today use strain gauge load cell6s. They work by bonding a strain gauge, which is a very fine wire or foil, to the load cell's structure. When a load is applied, the structure deforms, and the gauge stretches or compresses with it. This changes the electrical resistance of the gauge, which is measured by a Wheatstone bridge circuit. This technology is incredibly accurate, stable, and cost-effective, which is why we focus on it at Weigherps. It provides the reliability and simple integration that our global clients demand.

Specialized Load Cells for Niche Applications

While strain gauge types are the most common, other technologies are better suited for specific jobs.

| Type | Principle | Best For... |

|---|---|---|

| Hydraulic | Fluid Pressure | Very high capacities, harsh or remote environments without power |

| Pneumatic | Air Pressure | Intrinsically safe for hazardous or explosive environments |

| Piezoelectric | Electric Charge | Measuring rapidly changing (dynamic) loads with high precision |

Each technology has its place. For example, a pneumatic load cell7 is perfect for a chemical plant where electrical sparks are a major risk. A piezoelectric one is ideal for a lab testing the impact force of materials. But for 90% of industrial weighing1 applications, the strain gauge load cell is the most practical and effective solution.

What is the difference between a load cell and a scale?

People often use the terms 'load cell' and 'scale' as if they are the same thing. This confusion can lead to misunderstandings in technical discussions, especially when specifying a project.

A load cell is the sensor component that detects force. A scale is the complete weighing system that includes the load cell, a mechanical platform or structure, and an electronic indicator to display the weight. The load cell is the heart of the scale.

A useful way I explain this to clients is by using an analogy. Think of a car. A load cell is like the engine—it's the core component that does the work, but it can’t get you anywhere on its own. A scale is the entire car—it includes the engine, the chassis, the wheels, and the dashboard. You need the whole system to have a functional product. As an OEM and ODM manufacturer, we provide both the "engines" and the "complete cars" for our clients, depending on what their market needs.

The Load Cell as the 'Heart'

The load cell is purely a sensor. Its only job is to detect a force and convert it into a raw, low-level electrical signal. By itself, this signal is useless. It needs to be processed, converted, and interpreted by another device. It has no display, no buttons, and no platform. It is a critical component, but it's only one piece of the puzzle. When a customer buys just a load cell from us, they are typically integrating it into their own larger machine or system.

The Scale as the 'Body'

A scale is the complete system that the end-user interacts with. It's built around one or more load cells and includes all the other necessary parts to make it work.

| System Component | Role | Analogy |

|---|---|---|

| Load Cell(s) | Senses force and creates an electrical signal | Heart |

| Junction Box | Sums signals from multiple load cells (on larger scales) | Nervous System |

| Indicator/Terminal | Processes the signal and displays a weight reading | Brain & Face |

| Platform/Frame | Supports the object being weighed | Skeleton |

When you step on a bathroom scale or weigh a package on a bench scale, you are using a complete weighing system. The load cell is hidden inside, doing its job quietly.

What is load cell calibration?

You've installed a new weighing system, but how can you truly trust its readings? Uncalibrated equipment delivers inaccurate data, leading to quality issues, disputes, and non-compliance with regulations.

Load cell calibration is the process of comparing a scale's output reading against a known, certified weight (a standard). This verifies and adjusts the system to ensure its measurements are accurate, repeatable, and traceable. It is essential for reliability.

In my business, accuracy is not a feature; it's a requirement. Calibration is the process that guarantees this accuracy. Before any product leaves our facility, our quality control department performs a comprehensive test and calibration. We do this because we know our clients' success depends on the trustworthiness of the data our products provide. It's a non-negotiable step that ensures the equipment will perform perfectly from day one. It's also something that needs to be done regularly throughout the product's life.

Why Calibration is Non-Negotiable

Over time, a scale's accuracy can drift. This can be caused by normal wear and tear, temperature fluctuations, mechanical stress from overloading, or simply the aging of electronic components. Calibration corrects this drift. For businesses that trade by weight or must meet strict quality standards (like our CE-certified products), regular calibration is often a legal or contractual requirement. It provides a "proof of accuracy" that is traceable to a known national or international standard, giving you and your customers complete confidence in every measurement. This is especially vital for software providers who need to guarantee the integrity of the data their systems collect.

The Calibration Process Simplified

While the tools can be sophisticated, the process itself is straightforward.

- Check the 'Zero' Point: First, the scale is cleared to ensure it reads zero when there is no load on it.

- Apply a Known Weight: A certified test weight is placed on the scale. The mass of this weight is known to a very high degree of accuracy.

- Compare the Reading: The technician compares the scale's displayed reading to the known mass of the test weight.

- Make Adjustments: If there is a difference, the technician adjusts the scale's indicator so that its reading perfectly matches the known weight.

This process is typically repeated with weights at different points in the scale's capacity to ensure accuracy across its entire weighing range.

Conclusion

The load cell is the sensor at the heart of any scale. It comes in different types for different jobs and must be calibrated to ensure the accuracy that modern industry demands.

-

Gain insights into effective industrial weighing practices that enhance accuracy and efficiency. ↩ ↩

-

Understanding load cells is crucial for accurate measurements in various industries, ensuring efficiency and compliance. ↩

-

Understand the critical role of load cells in automation and improving operational efficiency. ↩

-

Discover the importance of data conversion in translating physical force into usable information. ↩

-

Explore the technology behind load cells and how they translate force into electrical signals. ↩

-

Learn about the most common type of load cell, its accuracy, and why it's widely used in industries. ↩

-

Learn about pneumatic load cells and their safety features in hazardous environments. ↩

Comments (0)