Manual packing is slow and costly. Inaccurate weights lead to product loss and unhappy customers. A packing scale machine automates this, ensuring fast, precise packaging every time.

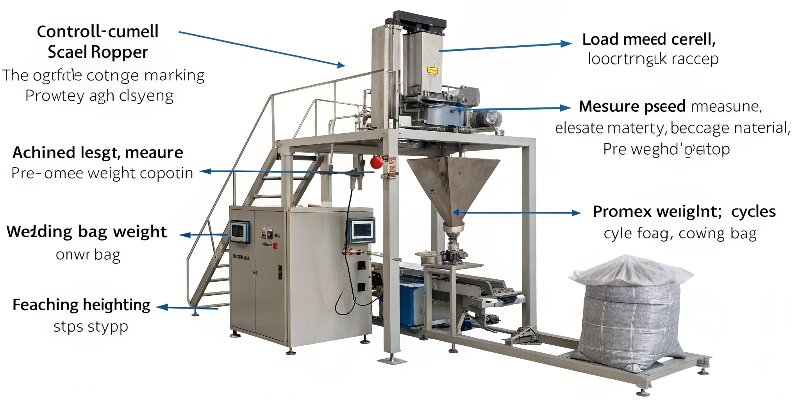

A packing scale machine is an automated system that accurately weighs and dispenses products into bags or containers. It combines a weighing system, feeding mechanism, and control unit to streamline packaging processes, significantly improving speed, consistency, and efficiency while reducing the need for manual labor.

It sounds simple, right? But the real value is in the details of how it all works together. I've been in this industry for 18 years, and I've seen these machines transform production floors. They aren't just pieces of equipment; they are the heart of an efficient packaging line.

To really understand its value, we need to look closer at how it revolutionizes the industrial packaging workflow. Let's explore how these machines actually work, what they're made of, what they can handle, and how to keep them running smoothly.

How does a packing scale machine function in industrial packaging processes?

Unsure how an automated packer works in your line? A misunderstanding can lead to costly integration mistakes. Let's break down the simple, step-by-step process for seamless operation.

The machine feeds material into a weighing hopper using a controlled mechanism. Once the pre-set weight is precisely measured by load cells, the feeding stops. The hopper then discharges the weighed material into a bag or container, completing one cycle and immediately preparing for the next.

Let's dive deeper into the operational flow. The entire process is a beautifully coordinated sequence managed by the machine’s brain, the control unit1. From my experience helping clients integrate these systems, understanding this flow is key to appreciating their power.

The Control Unit: The Brain of the Operation

Everything starts when an operator inputs the target weight into the control panel. This tells the machine exactly how much product should go into each bag. The control unit then orchestrates the entire cycle, from feeding to discharge. As a manufacturer, we've seen how crucial it is for this control software to communicate with other systems. It’s not just about the hardware; it’s about creating a cohesive, automated ecosystem. This is why having an open architecture or clear communication protocols is a key feature we focus on. This allows our clients' software and technical teams to integrate our hardware smoothly into their existing factory management systems.

The Feeding Process: A Two-Stage Approach

For maximum accuracy, most modern packing scales use a two-stage feeding process2.

- Fast Feed: The machine starts by feeding material quickly to get close to the target weight, say around 95%. This maximizes speed.

- Slow Feed: As the weight approaches the target, the feeding mechanism slows down to a "dribble." This fine-tunes the final amount, ensuring incredible accuracy and minimizing product giveaway.

This two-stage approach combines high speed with high precision, which is a game-changer for production efficiency and cost control.

What are the main components and features of a packing scale machine?

Confused by technical spec sheets? Choosing the wrong components can be a costly mistake. We'll break down the essential parts and features so you can make an informed decision.

Key components include the material inlet, a feeding mechanism (like a screw or vibratory feeder), a weighing hopper with high-precision load cells, and a control unit (PLC). Essential features often include digital displays, multi-stage feeding for accuracy, and dust control systems for clean operation.

A packing scale machine3 is more than the sum of its parts, but knowing the parts helps you choose the right machine. When I talk to purchasing managers or technical directors, I always emphasize that the quality of each component directly impacts reliability and performance. Cheap components can lead to frequent downtime and inaccurate weights. Here’s a breakdown of what you need to pay attention to.

Core Hardware Components

These are the physical parts that do the heavy lifting. The quality and design of these parts determine the machine's durability and suitability for your specific product.

| Component | Function | Why It's Important for You |

|---|---|---|

| Weighing System | Uses high-precision load cells4 to accurately measure the weight of the product in the hopper. | This is the heart of the machine. High-quality load cells ensure consistent product weight, reduce giveaway, and maintain customer trust. |

| Feeding Mechanism | Controls the flow of material into the weighing hopper. Common types are screw, vibratory, and gravity feeders. | The choice of feeder must match your product's properties. The right one prevents blockages and ensures a steady, controllable flow for accuracy. |

| Control Unit (PLC) | The digital brain that manages the entire weighing and packing cycle, including feeding speeds and discharge. | A good PLC allows for easy parameter changes, recipe storage, and integration with other factory systems. For software vendors, this is key for compatibility. |

| Discharge Gate/Hopper | A pneumatically or mechanically operated door that opens to release the weighed product into the package. | Must be fast-acting and create a tight seal to prevent product leakage and ensure the correct final bag weight. |

Key Software and Control Features

Beyond the hardware, the software is what makes the machine smart and user-friendly. In my experience, technical directors are very interested in how a machine can be integrated and controlled. They look for flexible software, frequent updates, and the ability to connect to new technologies. Modern machines should offer IoT capabilities for remote monitoring and data collection, empowering businesses to achieve a quantum leap in development.

What types of products can be weighed and packed using a packing scale machine?

Is your product too unique for standard packers? This concern can halt automation plans. In reality, these machines are highly versatile and can handle a wide variety of materials.

Packing scales are ideal for free-flowing granular and powdered products. This includes agricultural products like seeds and grains, food items like sugar and coffee, and industrial materials like plastic pellets and chemical powders. The machine type is chosen based on the material's flow characteristics.

Versatility is one of the biggest strengths of a packing scale machine3. Over my 18 years in this business, I've configured these machines for almost every industry imaginable. The key is to match the machine's feeding mechanism to the material's properties.

Granular vs. Powdered Materials

The main distinction we make is between granules and powders.

- Granular Materials: These are products like rice, plastic pellets, seeds, sugar, salt, and coffee beans. They flow easily, so they typically work well with gravity-fed or vibratory-fed systems. These feeders use vibration or a simple gate to control the product flow into the weigh hopper.

- Powdered Materials: These are products like flour, cement, detergent powder, and milk powder. They can be less free-flowing and may "bridge" or clump, blocking flow. For these, we use a screw feeder (or auger feeder). The turning screw actively pushes the powder forward, ensuring a consistent and controllable feed rate, even with difficult materials.

Customization for Your Product

As a manufacturer specializing in OEM/ODM solutions, we understand that one size does not fit all. We often work with clients who have unique products. I remember a client with a slightly sticky powdered spice mix. A standard screw feeder wasn't enough; the product would build up. So, our R&D team designed a solution with a special non-stick coating and an agitator in the main hopper to keep the product moving. This is where experience matters. We don't just sell a machine; we provide a targeted and cost-effective weighing solution that works for your specific material.

How do you maintain and troubleshoot a packing scale machine for optimal performance?

Worried about a machine breakdown halting production? Unexpected downtime is incredibly costly. With a simple maintenance schedule and basic troubleshooting knowledge, you can ensure optimal, continuous performance.

Regular maintenance involves cleaning material contact parts, checking for wear, and calibrating the load cells periodically. For troubleshooting, start by checking air pressure and sensor connections. Modern machines often have self-diagnostic features and modular designs, simplifying repairs by allowing quick component swaps.

Buying a machine is just the first step. Keeping it running at peak performance is what guarantees your return on investment. From my experience, the biggest pain point for any production manager is downtime. A simple preventive maintenance5 routine can prevent the vast majority of problems.

A Simple Preventive Maintenance Checklist

- Daily: Clean any product spills from the machine body and around the weighing area. Visually inspect sensors to ensure they are clean and unobstructed.

- Weekly: Check the compressed air supply for correct pressure and moisture. Use a certified test weight to quickly verify the scale's calibration. This takes seconds but can save you from producing out-of-spec packages.

- Monthly: Inspect any mechanical wear parts, like the seals on the discharge gate or the screw in a screw feeder. Lubricate moving parts according to the manufacturer's guide.

Common Troubleshooting Steps

When something goes wrong, a methodical approach is best.

- Inaccurate Weights: The most common issue. First, check for any product buildup on the weigh hopper that could affect its reading. Next, ensure there are no drafts or vibrations from nearby equipment. Finally, perform a full calibration as per the manual.

- Machine Won't Start: Check the simple things first. Is the power on? Is the emergency stop button engaged? Is the air supply connected and pressurized? Are all safety guards in place and their sensors active?

From my experience, the design of the machine is as important as the support behind it. That’s why we provide a 12-month after-sales service guarantee and ensure every product passes comprehensive testing before it ships. We know that having a reliable partner who can quickly help diagnose an issue or ship a replacement part is key to minimizing downtime.

Conclusion

A packing scale machine automates weighing for efficiency and accuracy. Understanding its function, components, and maintenance empowers you to choose the right solution and boost your production line.

-

Understand how control units manage operations and improve integration with factory systems. ↩

-

Learn how a two-stage feeding process enhances speed and accuracy in packaging. ↩

-

Explore this link to understand the mechanics and benefits of packing scale machines in industrial settings. ↩ ↩

-

Explore the significance of load cells in maintaining accurate weight measurements. ↩

-

Understand the importance of preventive maintenance in ensuring machine longevity and performance. ↩

Comments (0)