Are you struggling to find accurate and reliable ways to measure weight? Using the wrong technology can cause major errors in your production line or product, costing you money and time.

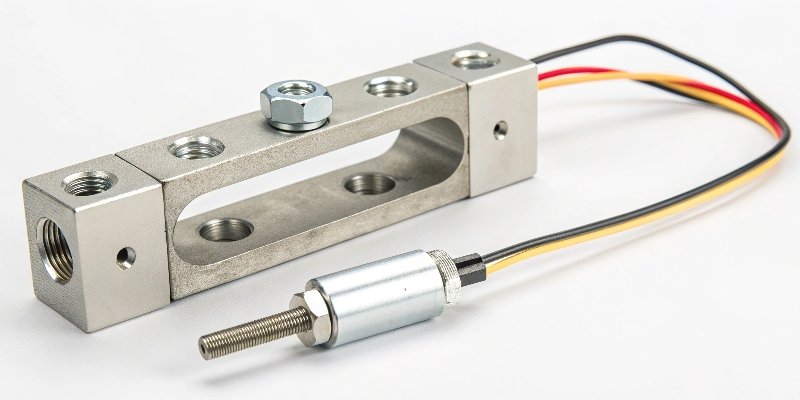

A strain gauge load cell is the heart of most modern electronic scales. It's a highly precise sensor that converts the physical force of weight into a measurable electrical signal. This allows you to accurately determine the weight of almost anything, from small lab samples to heavy industrial loads.

This small but powerful device is the key component that makes digital weighing possible. As a manufacturer with over 18 years of experience, I've built my company around perfecting this technology. But to truly appreciate how it works and why it's so reliable, we need to break it down. Understanding its parts helps you choose the right product and troubleshoot any issues.

Let's dive into the core components to see how they all work together.

What is a strain gauge for a load cell?

You often hear the term "strain gauge" when talking about weighing. But not knowing exactly what it is can make the whole concept seem complicated and mysterious.

A strain gauge is a tiny, flexible sensor made of a metal foil pattern. It is bonded directly onto the load cell's body. When the body bends under weight, the strain gauge stretches or compresses with it, causing its electrical resistance to change.

Think of the strain gauge1 as the nerve ending of the load cell. It's the part that actually "feels" the force. In my experience, the quality of this tiny component is critical for the overall accuracy and longevity of the scale. It's a simple part, but it has a very important job.

The Structure of a Strain Gauge

A strain gauge is typically made from a very thin metal foil2 arranged in a grid-like pattern. This pattern maximizes the length of the foil in a small area, making it more sensitive to changes. The foil is bonded to a flexible backing material, which is then glued to the surface of the load cell's elastic body. When the body deforms, the gauge is forced to deform with it.

How Resistance Changes

The working principle is based on a physical property called the piezoresistive effect3. When you stretch the metal foil, it becomes longer and thinner, which increases its electrical resistance. When you compress it, it becomes shorter and thicker, which decreases its resistance. This change in resistance, though very small, is directly proportional to the amount of strain.

How does a strain gauge load cell work?

Knowing the parts is helpful, but the real question is how they work together. Without understanding the process, it's hard to feel confident in the technology or diagnose problems.

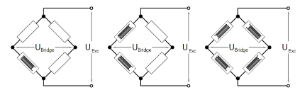

When weight is placed on a load cell, its metal body deforms slightly. The strain gauges attached to it also deform, changing their resistance. This change unbalances a circuit called a Wheatstone bridge, which then produces a small voltage signal directly proportional to the applied weight.

The entire process is a perfect example of converting one form of energy into another—from physical force to an electrical signal. At our factory, we calibrate this process with extreme precision to ensure every load cell we produce is reliable. We can break down the process into a few simple steps.

Step-by-Step Conversion Process

The conversion of force into a readable signal follows a clear sequence. Each step builds on the last to create a precise measurement tool.

| Step | Action | Description |

|---|---|---|

| 1 | Force Application | An object's weight is placed on the scale, applying force to the load cell. |

| 2 | Elastic Deformation | The load cell's metal structure bends or compresses by a microscopic amount. |

| 3 | Resistance Change | The strain gauges on the body stretch or compress, changing their electrical resistance. |

| 4 | Signal Output | The Wheatstone bridge4 circuit detects the resistance change and outputs a proportional mV voltage signal. |

This small analog signal is then sent to an indicator or a PLC, where it is amplified and converted into a digital weight reading that you see on the screen.

Is a strain gauge the same as a load cell?

People in the industry sometimes use "strain gauge" and "load cell" as if they are the same thing. This confusion can lead to mistakes when ordering parts or discussing technical needs.

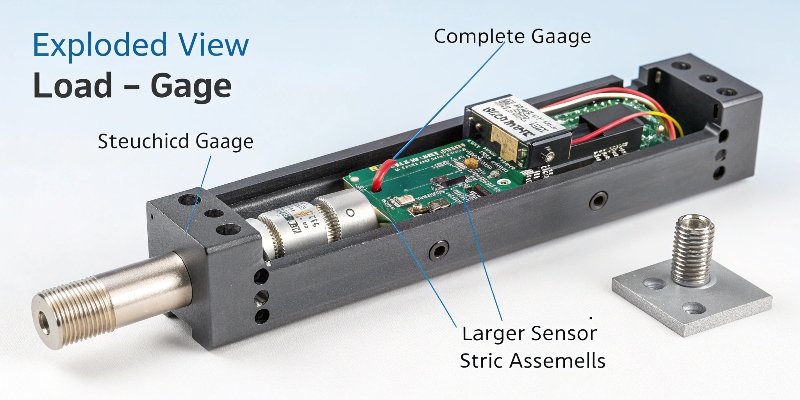

No, a strain gauge and a load cell are not the same. A strain gauge is just one part, the tiny sensor that detects deformation. A load cell is the complete mechanical assembly that uses one or more strain gauges to measure force.

Think of it this way: a strain gauge is like a single string on a guitar. A load cell is the entire guitar—the body, neck, and strings all working together to produce music. You can't play a melody with just one string; you need the whole instrument. In the same way, you need a full load cell assembly5 to accurately measure weight. As a manufacturer, we don't just sell the "strings"; we build the "instrument" and make sure it's perfectly tuned for our clients.

Component vs. System

The key difference lies in their function and complexity. This table helps clarify the distinction.

| Feature | Strain Gauge | Load Cell |

|---|---|---|

| Function | Measures strain (deformation). | Measures force or weight. |

| Composition | A single sensor (metal foil). | A complete system (metal body, gauges, wiring). |

| Output | A change in electrical resistance. | A calibrated voltage (mV) or digital signal. |

| Use | A component used inside a sensor. | A complete component for a weighing system. |

You can't just buy a strain gauge and expect to weigh something. It needs to be carefully mounted on a precisely engineered metal body and wired into a circuit to function as a load cell.

What is the purpose of a strain gauge?

We know what a strain gauge is and that it's crucial for a load cell. But what is its fundamental job? Underestimating its purpose can make you overlook its importance in your system's final accuracy.

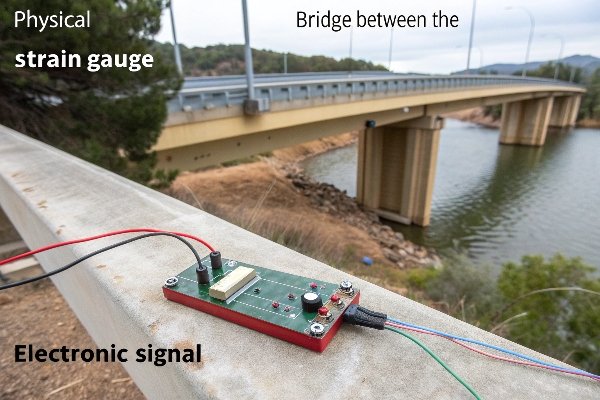

The main purpose of a strain gauge is to act as a transducer. It converts a physical deformation, which is hard to measure directly, into a change in an electrical property—resistance—which is very easy to measure precisely. It's the bridge between the physical world and the electronic one.

In my 18 years in this business, I've seen firsthand how the quality of this simple component affects the entire weighing system6. A high-quality strain gauge is the foundation of a reliable and accurate scale. That’s why at Weigherps, we are meticulous about the sourcing and application of every single strain gauge we use. Its purpose goes beyond just one function; its characteristics are what make modern weighing possible.

Key Characteristics for Weighing

Several unique features make strain gauges perfect for their job.

High Sensitivity

Strain gauges are incredibly sensitive. They can detect changes in length that are too small for the human eye to see. This sensitivity is what allows a load cell to provide precise, high-resolution weight measurements, whether it's for a gram in a lab or a ton on a truck.

Reliability and Versatility

When properly manufactured and installed, a strain gauge provides consistent and repeatable results. It will give the same electrical response for the same amount of force time after time. This reliability is essential for industrial automation7 and quality control. Its use isn't limited to scales, either—strain gauges are also used to monitor the structural health of bridges, test materials in aerospace, and in various medical devices.

Conclusion

The strain gauge load cell is the foundation of modern weighing. It reliably converts physical force into a clean electrical signal, enabling the precise measurements your business depends on.

- Discover the role of strain gauges in load cells for better accuracy in weighing systems. ↩

- Understanding the material used in strain gauges can enhance your knowledge of their performance. ↩

- Understanding this effect is crucial for grasping how strain gauges measure weight. ↩

- This link will clarify the circuit that plays a key role in weight measurement. ↩

- Learn about the assembly process to appreciate the complexity of load cells. ↩

- Explore the components of weighing systems to understand their functionality better. ↩

- Learn about the applications of strain gauges in automation for improved efficiency. ↩

[…] strain gauge works because of something called the piezoresistive effect6. In simple terms, when the metallic foil of the gauge is stretched, it gets longer and thinner, […]

[…] I’ve seen this difference cause major issues. An analog scale relies on a principle called the piezoresistive effect2. A force deforms an elastic component, which changes the resistance of a connected strain gauge. A […]