Are you losing time and money by weighing items one by one? Dynamic weighing offers a solution for objects in motion, turning a slow process into a seamless one.

Dynamic weighing measures the weight of objects while they are moving, like on a conveyor belt. It uses special algorithms to filter out vibrations and motion. This provides an accurate weight without ever stopping your production line.

For 18 years, I've seen countless companies struggle with production bottlenecks. A common culprit is often the weighing process1. You have a fast-moving production line, but everything grinds to a halt just to get a weight measurement. It feels like putting a traffic light on a highway. The good news is, technology has a very effective answer for this. Understanding what dynamic weighing is and how it works can completely change how you see your production flow. Let's explore if this is the leap forward your business needs to stay competitive and efficient.

How does dynamic weighing work to get an accurate measurement?

Weighing something that's moving seems impossible, right? Vibrations from a conveyor and the object's speed can easily throw off a normal scale's reading. But our systems use advanced technology.

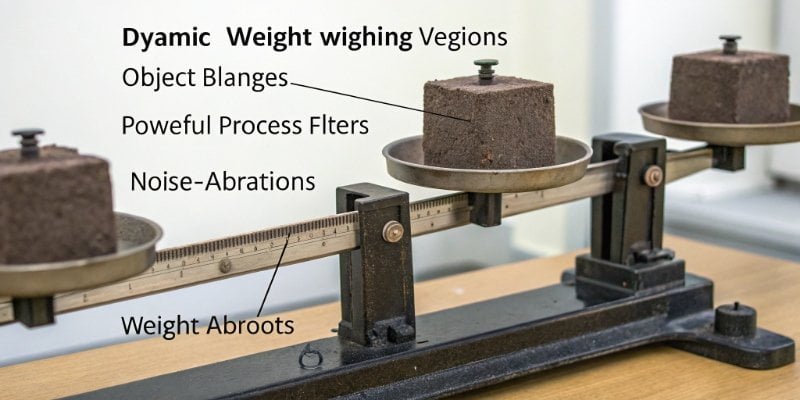

It works by taking many weight readings in a very short time as the object passes over the scale. A powerful processor then averages these readings and uses a filter to ignore "noise" like vibrations, calculating the object's true weight.

From my experience in our R&D department, the magic is all in the software and sensors. It’s not just one measurement, but a rapid-fire sequence of them. Think of it like a camera taking a burst of photos to get one perfect, non-blurry shot. A dynamic scale does the same with weight.

Here’s a simple breakdown of the steps:

The Measurement Process

- Detection: A sensor detects when an item enters the weighing section of the conveyor.

- Rapid Sampling: As the item moves across the load cells, the system takes hundreds or thousands of weight measurements2 in milliseconds.

- Signal Filtering: This is the key part. A digital filter algorithm analyzes the stream of data. It intelligently separates the consistent force of the item's weight from the erratic "noise" of machine vibrations and movement.

- Calculation: The filtered data points are used to calculate a single, stable, and accurate weight value.

- Action: This final weight is then displayed, recorded, or used to trigger another action, like sorting the package down a different chute.

This entire process happens in the blink of an eye, ensuring your line keeps moving at full speed.

What is the difference between dynamic and static weighing?

You know you need to weigh things, but you're not sure which type of scale is right. Choosing the wrong one can create slowdowns and inefficiencies. But understanding the core difference is simple.

Static weighing measures an object when it is completely still. Dynamic weighing, or in-motion weighing, measures an object as it moves. The key difference is the need for speed and a continuous workflow, which only dynamic weighing provides.

In our factory, we manufacture both types of scales, and they serve very different purposes. A static scale is like a parking spot; you stop, get the job done, and then move on. It's perfect for things like weighing ingredients before mixing or checking a final pallet's weight before shipping. A dynamic scale is like an E-ZPass lane on the highway; you get measured without ever hitting the brakes. It's built for integration directly into a process. The technology inside is also fundamentally different. While a static scale just needs to find a stable reading, a dynamic scale needs a powerful processor to perform complex calculations in real-time.

Here is a table to make the differences clear:

| Feature | Static Weighing | Dynamic Weighing |

|---|---|---|

| Object State | Must be completely still | Is in constant motion |

| Process Speed | Slow; requires stopping the flow | Fast; integrated into a moving line |

| Best For | Manual tasks, labs, retail checkouts | Automated conveyor lines, logistics3, processing |

| Technology | Basic load cell reading | Advanced sensors and filtering algorithms |

| Throughput | Low to medium | High to very high |

What are the main benefits of using a dynamic weighing scale?

Your production line has bottlenecks that are costing you money. Stopping a fast-moving conveyor to weigh items wastes valuable time and requires extra labor. A dynamic scale can solve this problem.

The main benefits are higher throughput and efficiency. You avoid stopping your production line to weigh products. This saves time, reduces labor, and allows for 100% weight inspection of everything you produce, which improves quality control.

When we help clients switch from static spot-checking to dynamic weighing, the results are immediate. They are often surprised by how much hidden potential was locked up in their production line. The benefits go far beyond just speed.

Boost Your Productivity

By eliminating the stop-and-go weighing process1, you can increase the number of units you process per hour. This directly translates to higher output and sales capacity without needing to expand your facility.

Improve Your Quality Control

Instead of manually spot-checking a few items, you can automatically weigh every single one. This ensures no under-filled packages leave your factory, protecting your brand reputation, and no over-filled packages are sent out, saving you money on lost product.

Save on Costs

First, you reduce the need for manual labor to weigh items. Second, precise filling and package checking minimize product giveaway. Third, you avoid fines or penalties for shipping items that don't meet weight regulations. Over time, these savings add up significantly.

For what types of applications is dynamic weighing essential?

You might be wondering if your business really needs this kind of technology. Not using it in the right application can put you far behind your competitors. Let's see if your operation fits these common use cases.

Dynamic weighing is essential in logistics for sorting packages by weight, in food processing for checking fill levels, and in manufacturing for quality control. Any high-speed, conveyor-based system can see huge benefits from using it.

I've personally configured weighing systems for clients across many industries. While the products are different, the need for speed and accuracy is universal. If your business involves items moving on a conveyor, there's a good chance dynamic weighing is a perfect fit.

Here are some of the most critical applications:

Logistics and Shipping

This is the most common use. Every major courier uses dynamic scales to weigh and measure packages in motion. This data is used to calculate shipping charges and sort packages for delivery, all automatically.

Food and Beverage

In this industry, weight often equals quantity. A dynamic scale (also called a checkweigher) ensures every bag of snacks, frozen meal, or bottle of juice is filled to the correct level, complying with regulations and preventing product waste.

Pharmaceuticals

Accuracy is non-negotiable here. Dynamic scales are used to verify that the right number of pills are in a bottle or that a medical kit contains all its components, providing 100% quality assurance.

Manufacturing and Industrial

In factories, dynamic scales are used for quality control4. They can check the weight of parts as they come off the assembly line to ensure no material is missing.

Conclusion

Dynamic weighing boosts efficiency for items in motion. Integrating it helps you increase throughput, save on costs, and achieve total quality control, giving your business a real competitive advantage.

-

Discover best practices that can streamline your weighing process and improve productivity. ↩ ↩

-

Explore various methods to ensure accurate weight measurements in your operations. ↩

-

Learn how dynamic weighing streamlines logistics and improves shipping accuracy. ↩

-

Discover how dynamic weighing enhances quality control and reduces errors. ↩

Comments (0)