Getting inaccurate weights for your products? The weight of containers messes up your data, costing you money and efficiency. This simple concept is key to solving that problem.

Tare weight is the weight of a container, packaging, or vehicle without any contents inside. When you "tare" a scale, you set the display to zero while the empty container is on it. This ensures you only measure the product you add, giving you the true 'net weight'.

Now you have the basic definition. But this simple function is much more than a button on a scale. It's a fundamental concept that, when automated, becomes a powerful tool for industrial efficiency. Understanding how to leverage it can transform your production line, streamline your logistics, and protect your bottom line.

Let's dive deeper into what tare weight really means for your business and how you can use it to your advantage.

What does tare weight mean in practice?

Does your team just press the "tare" button without thinking? This simple mistake can cause big errors in your inventory and billing, leading to major financial losses.

In practice, taring means creating a zero reference point with an empty container. This action instructs the scale to ignore the container's weight in all future measurements. It ensures that the number you see on the display is only the weight of the product you are selling or tracking.

As a manufacturer of industrial scales1 for 19 years, I've seen how critical a proper taring process is. It goes beyond a single button press. The goal is to make this process foolproof and efficient. We can approach this in two ways: manual taring2, which relies on an operator, and intelligent taring3, which uses technology to automate the process.

Manual vs. Intelligent Taring

Manual taring is what most people are familiar with. An operator places an empty box, pallet, or drum on the scale and presses the "Tare" button. While simple, it's open to human error. An operator might forget to press the button or use the wrong container.

Intelligent taring removes this risk. I remember visiting a client's food processing plant. They were losing money due to inconsistent filling of large ingredient bins. We provided them with a custom IoT weighing system4. The system uses scanners to identify each bin, pulls its pre-registered tare weight from a database, and automatically applies it. This integration with their management software eliminated human error and ensured every batch was perfect. Your software can be the brain for this operation, and our scales provide the precise data.

What's the difference between tare weight, net weight, and gross weight?

Confused by weighing terms like net and gross? Mixing them up can lead to shipping overcharges, incorrect inventory counts, and even compliance fines. Let's clear up the confusion for good.

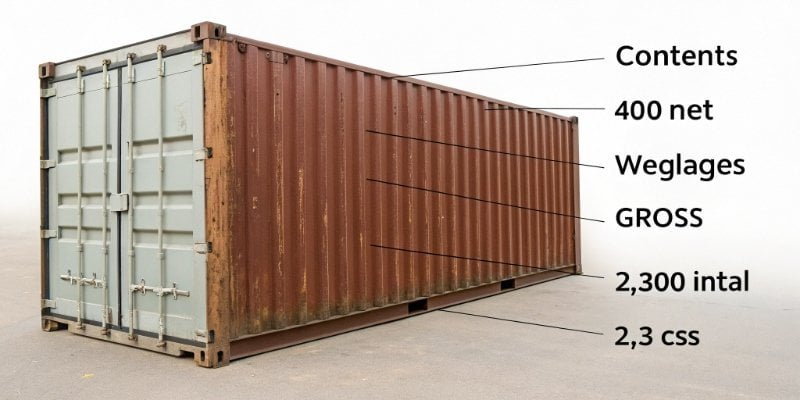

Tare weight is the container's weight. Net weight is the product's weight. Gross weight is the total combined weight of both. The simple formula is: Gross Weight = Net Weight + Tare Weight. Understanding this is essential for accurate business operations.

This distinction is the absolute foundation of inventory and logistics management5. For any software vendor designing systems for these industries, these three values—Tare, Net, and Gross—are non-negotiable data fields. Getting them right ensures data integrity6 from the factory floor to the customer's door.

The Fundamental Weighing Equation

Think of it like this: you can always calculate one value if you know the other two. This is critical for everything from billing clients to paying for shipping.

To make it crystal clear, here’s a breakdown using a common industrial example: a drum of chemicals.

| Term | Definition | Example (A drum of chemicals) |

|---|---|---|

| Tare Weight | The weight of the empty container. | The empty 200L steel drum weighs 20 kg. |

| Net Weight | The weight of the product itself. | The chemical liquid inside the drum weighs 220 kg. |

| Gross Weight | The total weight of the product and container. | The full drum on the shipping pallet weighs 240 kg. |

When your software integrates with a weighing system, it needs to handle these values separately. Our scales can be configured to send all three data points directly to your system via an API. This simplifies development for you and provides a more powerful, transparent solution for the end customer. They can see exactly what they are paying for: the product (net weight7) and the shipping (based on gross weight8).

How do modern scales calculate tare weight?

Still calculating tare weight manually by weighing containers separately and subtracting the value later? This old method is slow, error-prone, and kills your production efficiency. There is a much smarter way.

Modern scales calculate and apply tare weight almost instantly. You place the empty container on the weighing platform and press the "Tare" key. The scale's processor saves that weight and automatically subtracts it from the gross weight, displaying only the net weight from that point on.

The standard process is straightforward, but modern industrial weighing is about moving beyond the simple button press. As a provider of custom weighing solutions9, we focus on making this process invisible and intelligent, especially for our software vendor partners who need reliable, automated data.

The Standard Tare Function

- Place Container: The operator puts the empty container (e.g., a box, tote, or pallet) on the scale.

- Press Tare: The operator presses the "Tare" or "Zero" button. The scale's display will change to 0.00.

- Store Weight: Internally, the scale's memory now holds the container's weight.

- Add Product: The operator fills the container. The scale's display shows only the weight of the added product—the net weight.

Intelligent Taring: The Next Level of Efficiency

This is where true optimization happens. What if you could skip the manual steps entirely? Our advanced systems do just that. We delivered a solution for a major logistics company that handles thousands of standardized shipping totes daily. Their operators were wasting valuable time taring the scale for every single package.

Our solution integrated our scales with barcode scanners10 and their warehouse management system (WMS). When a tote is placed on the scale, the scanner reads its barcode. The WMS instantly sends the pre-programmed tare weight for that specific tote model to the scale via an API. The taring happens automatically in a fraction of a second. The operator just fills the tote. This small change increased their throughput by over 20%. This is the kind of seamless hardware-software integration we enable.

What is the difference between tare weight and GVM?

Do you manage vehicle weights for logistics? Confusing a vehicle's tare weight with its Gross Vehicle Mass (GVM) isn't just a simple mistake—it can lead to dangerous overloading, heavy fines, and serious legal trouble.

A vehicle's tare weight (also known as curb weight) is its weight when empty, including all standard equipment and a full tank of fuel. Gross Vehicle Mass (GVM) is the maximum legal weight of the vehicle including the driver, passengers, and all cargo.

This distinction is absolutely vital in the world of transportation and logistics. Your payload—the actual cargo you can legally and safely carry—is determined by the difference between these two figures. Overlooking this can have severe consequences for safety and compliance.

The Critical Payload Calculation

The most important formula in logistics is Maximum Payload = [GVM](https://en.wikipedia.org/wiki/Vehicle_weight)[^11] - Tare Weight. Your software must use this calculation to prevent overloading.

Let's break down these crucial vehicle weighing terms11 in a table:

| Term | Definition | What it Includes | What it Represents |

|---|---|---|---|

| Tare Weight | The weight of the empty, ready-to-operate vehicle. | The vehicle itself, all standard equipment, and a full fuel tank. | A baseline for calculating your payload capacity12. |

| GVM (Gross Vehicle Mass) | The maximum total weight the vehicle is designed and certified to carry, by law. | The vehicle's Tare Weight plus all contents (cargo, driver, passengers, etc.). | A non-negotiable legal and safety limit. |

As scale manufacturers, we provide the tools to enforce these limits, from heavy-duty weighbridge13s to portable axle weighers. For a software provider, integrating your logistics platform with our hardware is a game-changer. Imagine your software automatically flagging an overloaded truck before it leaves the depot. Our scales can send the real-time gross weight to your system, which then compares it against the registered GVM, providing a critical safety and compliance check. This makes your software solution indispensable to any fleet operator.

Conclusion

Understanding tare weight is simple, but leveraging it with smart technology is transformative. It's the key to boosting accuracy, efficiency, and profit in any industrial setting.

-

Explore the advantages of industrial scales for accurate measurements. ↩

-

Discover the limitations of manual taring and how it can lead to errors. ↩

-

Find out how automation in taring can enhance productivity and reduce errors. ↩

-

Discover how IoT technology is revolutionizing weighing processes. ↩

-

Learn how tare weight is crucial for efficient logistics operations. ↩

-

Explore the significance of data integrity for reliable logistics operations. ↩

-

Learn how net weight affects shipping costs and inventory management. ↩

-

Understand the importance of gross weight in logistics and compliance. ↩

-

Find out how tailored weighing solutions can meet specific business needs. ↩

-

Learn how barcode scanners enhance accuracy in weighing operations. ↩

-

Clarify essential weighing terms to avoid costly mistakes in logistics. ↩

-

Understand how to calculate payload capacity for safe and legal transport. ↩

-

Understand the function of weighbridges in vehicle weight management. ↩

Comments (0)