Are you puzzled by the different certificates that come with industrial equipment? This confusion can cause project delays and legal issues. Let's make the distinctions clear and simple.

A Certificate of Conformity (CoC) proves a product, like a scale, was manufactured to meet specific standards. A Certificate of Calibration, on the other hand, verifies that the scale provides accurate measurements against a known, traceable standard. One is about product quality, the other about measurement accuracy.

Understanding this difference is crucial for any business that relies on accurate measurements and compliant products. Over my 18 years in this industry, I’ve seen clients face major setbacks because they had one certificate when they actually needed the other. It’s a simple mistake, but the consequences can be significant. Let’s break it down further so you can avoid these pitfalls and ensure your operations run smoothly from day one.

Is a certificate of conformity the same as a calibration certificate?

Thinking a Certificate of Conformity (CoC) can replace a calibration certificate? This common mistake can lead to failed audits and rejected shipments. Let's explore why they are not the same.

No, they are definitely not the same. A CoC confirms a product's design and manufacturing quality meet required regulations like CE. A calibration certificate confirms a specific instrument's measurement accuracy at a point in time. One certifies overall compliance, the other certifies operational precision.

I remember a situation with a new client in the logistics industry. They purchased a set of our truck scales and proudly presented the Certificate of Conformity1 during a regulatory inspection2. The auditor, however, asked for the calibration certificate to verify the scales' accuracy for trade use. The client was stuck, and their launch was delayed. This highlights the core difference: a CoC is about the product as designed, while calibration is about the product's performance in use. The CoC shows we built the scale right; the calibration certificate shows it measures right. For any commercial or legally regulated weighing, you need both documents to be fully compliant and operational.

| Aspect | Certificate of Conformity (CoC) | Certificate of Calibration3 |

|---|---|---|

| Purpose | Proves product meets quality standards | Proves measurement accuracy4 |

| Focus | Product quality, safety, & design | Instrument performance & precision |

| When Issued | After manufacturing, before sale | After a calibration service is done |

| Typical Application | Product sales, contract bids, imports | Lab equipment, production scales |

Are CoC and CoA the same?

Facing another confusing acronym, CoA? Using it interchangeably with CoC can lead to serious compliance failures, especially in regulated industries like food or pharmaceuticals. Let's clear up this common confusion.

No, a CoC (Certificate of Conformity) and a CoA (Certificate of Analysis) are different. A CoC confirms a general product meets standards. A CoA provides detailed test results for a specific batch of a material, like its exact chemical composition.

This distinction is most critical for our clients in sectors like pharmaceuticals or food processing. A CoC for one of our stainless steel scales confirms it meets CE standards5 for electrical safety and design. However, if that scale will be used on a food production line, the client might also need a CoA for the specific lot of stainless steel used in its construction. This CoA proves it is food-grade 316L stainless steel, detailing its exact material composition. So, the CoC is broad—it says "this type of scale is compliant." The CoA is specific—it says "this exact component has these verified properties." You need both to satisfy different layers of quality assurance.

| Document | Certificate of Conformity (CoC) | Certificate of Analysis (CoA) |

|---|---|---|

| What it Confirms | Conformance to regulations or standards | Specific properties of a single batch |

| Scope | Entire product model or series | A specific lot or batch of material |

| Information Provided | Declaration of compliance with rules | Quantitative test results (e.g., %) |

| Common Industries | Electronics, machinery, general goods | Chemicals, pharmaceuticals, food |

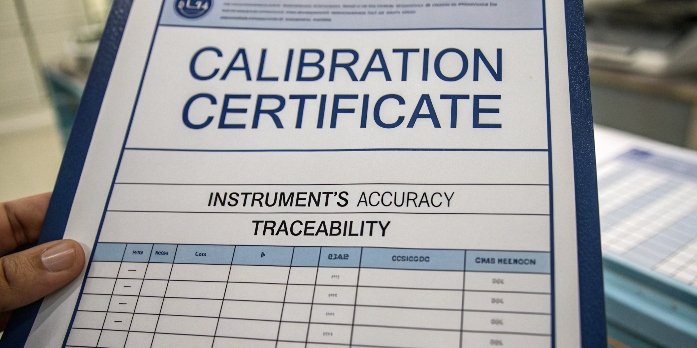

What does a calibration certificate mean?

Do you really know what a calibration certificate guarantees? Simply having one isn't enough; assuming it means your scale is perfect can lead to costly production errors. Let's break down what it actually tells you.

A calibration certificate is a formal document that proves a measuring instrument has been tested against a traceable standard. It details the instrument's accuracy and any deviation (error) found, confirming its performance is within acceptable limits for your specific needs.

Think of it as your scale's detailed report card. It doesn’t just say "pass." It provides concrete data. For instance, we recently calibrated a high-precision scale for a client who develops software for laboratories. The certificate showed that when a 100.00g standard weight was placed on the scale, it read 100.01g. This tiny +0.01g deviation is documented. The certificate also confirms that the standard weight used for testing is itself traceable to a national standard body. This "chain of traceability6" is what gives you confidence in your measurements. It means you have documented proof of your scale’s performance, which is essential for quality control, regulatory compliance, and building trust with your own clients.

What is the difference between calibration and certification?

Do the words "calibration" and "certification" blur together for you? Confusing the process with the proof can leave your operations exposed during audits. Let's separate these two critical concepts.

Calibration is the physical act of comparing a measurement device to a known standard and adjusting it for accuracy. Certification is the documentation process that provides a formal certificate as proof that the calibration was performed correctly and the device meets requirements.

As a manufacturer, we perform both steps, but they are distinct. Calibration is the hands-on work. Our technicians take a scale, apply certified test weights, and compare the scale's reading to the weight's true mass. If there's a difference outside the tolerance, they adjust the scale's internal settings. That is the action of calibration. But that action alone isn't enough proof for our clients. Certification is the documentation that follows. We issue a calibration certificate that details what we did, the standards we used, the "as found" and "as left" results, and a statement of traceability. One is the service; the other is the official record of that service. You simply cannot have a valid certification without a proper calibration first.

| Concept | Calibration | Certification |

|---|---|---|

| Nature | A physical process, an action | A documentation process, providing proof |

| Goal | To ensure an instrument's accuracy | To formally document and verify that accuracy |

| What You Do | Compare a device to a standard, then adjust it | Record results, state compliance, issue a certificate |

| Output | An adjusted, accurate instrument | A formal document (the Calibration Certificate) |

Conclusion

In short, a CoC proves product compliance, while a calibration certificate proves measurement accuracy. Understanding this difference is key to ensuring both quality and precision in your operations.

-

Explore this link to understand how a CoC ensures product compliance with industry standards. ↩

-

Get insights on preparing for regulatory inspections to avoid compliance issues. ↩

-

Learn about the significance of calibration certificates in ensuring measurement accuracy for your equipment. ↩

-

Find out how measurement accuracy affects production and regulatory compliance. ↩

-

Understand the significance of CE standards in product compliance and safety. ↩

-

Understand the importance of traceability in ensuring measurement accuracy. ↩

[…] compatibility4, and environmental protection. It applies to a huge range of products. A Calibration Certificate5, however, has a much narrower and more specific goal: to prove measurement accuracy. It is only […]