Are you struggling to get accurate readings from your strain sensors? Choosing the wrong setup can lead to bad data, costing you time and money and affecting your product's reliability.

A quarter-bridge uses one active strain gauge, a half-bridge uses two, and a full-bridge uses four. The more gauges in the circuit, the higher the sensitivity, accuracy, and compensation for temperature, with the full-bridge being the most precise configuration for high-performance weighing systems.

But simply adding more gauges isn't the whole story. The way they are arranged in the circuit is what gives each configuration its unique advantages. Understanding this is crucial for anyone who needs to integrate a weighing sensor with their software systems. To pick the right setup for your project, you need to know how they work and where they shine. Let's start with how these circuits handle a common enemy for all sensors: temperature.

How does a Wheatstone bridge help compensate for temperature in measurements?

Temperature changes make materials expand and contract, creating false readings in your sensor. This thermal error can make your carefully collected data completely unreliable, leading to costly system failures.

A Wheatstone bridge minimizes temperature errors by using multiple gauges. As temperature changes, the resistance of all gauges changes equally. By placing them in adjacent arms of the bridge, these identical resistance changes cancel each other out, isolating the true mechanical strain from thermal noise.

Imagine a simple strain gauge1 glued to a steel bar. When the temperature rises, both the steel bar and the gauge itself expand. This expansion stretches the gauge, changing its resistance and creating a signal that looks just like a mechanical load. Your system can't tell the difference. This is a huge problem.

The brilliance of the Wheatstone bridge2 is how it turns this problem against itself. By including a second "dummy" gauge that is exposed to the same temperature but not the mechanical strain3, we can create a self-correcting system. The active gauge measures temperature and strain. The dummy gauge4 measures only temperature. When we place them in the bridge circuit, the temperature effect from the active gauge is subtracted, leaving only the signal from the real strain. This is a fundamental technique we've relied on for years to build stable, reliable industrial scales that perform in harsh, fluctuating environments.

| Configuration | Temperature Effect | Strain Measurement |

|---|---|---|

| Single Gauge | High (Causes significant error) | Measures strain + temperature noise |

| Bridge with Dummy Gauge | Low (Effect is canceled out) | Measures true strain only |

This physical compensation is far more effective than trying to correct for temperature in software, as it removes the error at the source.

What is a quarter-bridge (1/4 bridge) and when is it used for strain measurement?

You need a simple, low-cost way to measure strain, but just one gauge feels incomplete. You worry about inaccuracies from temperature and other factors, making your simple project more complicated.

A quarter-bridge uses one active strain gauge and three precision fixed resistors to complete the circuit. It's best for simple tension or compression measurements where cost is the main driver and environmental conditions are stable or can be compensated for externally.

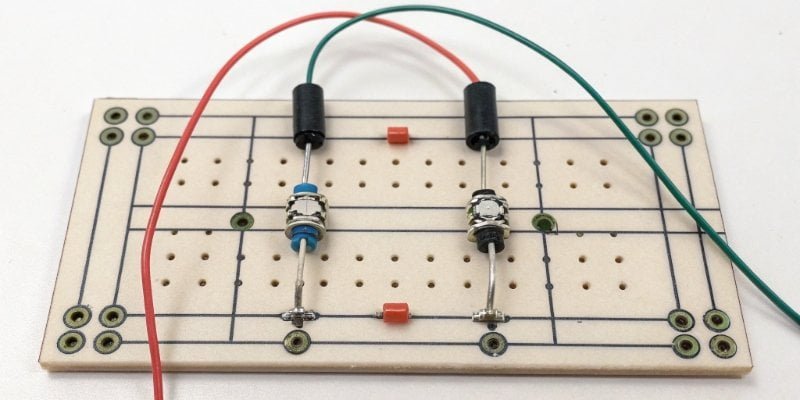

Think of the quarter-bridge5 as the most basic entry point into strain measurement. It's just one sensor doing all the work. We use this configuration in situations where the customer needs a "good enough" measurement on a very tight budget. For example, in some simple, consumer-grade scales I've seen, this setup is common. You place one active gauge to measure the force and complete the Wheatstone bridge with three stable, inexpensive resistors inside the electronics housing.

However, its simplicity is also its biggest weakness. It has the lowest sensitivity6 of the three configurations and is highly susceptible to temperature changes, as we discussed. It's also affected by changes in the resistance of the lead wires running from the sensor to the electronics, especially over long distances. For many of our clients developing software for industrial devices, this configuration often lacks the stability and precision needed for a reliable product. We generally recommend it only for low-cost scenarios, like basic weighing projects, where a 1/4 bridge with external compensation can meet the minimum requirements.

| Aspect | Quarter-Bridge (1/4) |

|---|---|

| Pros | Simplest to wire, lowest cost |

| Cons | Low sensitivity, poor temperature compensation7, susceptible to wire resistance errors |

| Best Use | Non-critical academic experiments, simple demonstrations, very low-cost scales |

What are the main advantages of using a half-bridge (1/2 bridge) circuit?

A quarter-bridge isn't accurate enough for your application, but a full-bridge seems too complex or expensive. You're caught between poor data quality and over-engineering, which can hurt your budget.

A half-bridge uses two active strain gauges, doubling the output signal compared to a quarter-bridge. Its key advantages include better sensitivity and built-in temperature compensation, making it a great cost-effective choice for many industrial applications like bending measurement or simple load cells.

The half-bridge8 is the smart middle ground, and it's a configuration we use often at our manufacturing facility. By using two gauges, you solve the biggest problems of the quarter-bridge. The most common setup is for measuring bending. You place one gauge on the top surface of a beam (which will be in tension) and another gauge on the bottom surface (which will be in compression). When the beam bends, one gauge's resistance increases, and the other's decreases. Wiring them into the bridge circuit doubles the output signal, immediately giving you better resolution for your software to work with.

Crucially, because both gauges are mounted on the same part, they experience the same temperature. Any resistance change due to heat affects both gauges equally but in opposite ways in the circuit, effectively canceling out the thermal error. This provides good, clean data. In my 19 years of OEM experience, we've found the half-bridge is the workhorse for many industrial applications9, like electronic crane scales. It delivers the perfect balance of performance and cost, providing the robust and accurate data our B2B clients need for their industrial systems.

Why is a full-bridge circuit the most accurate configuration for sensors?

For your precision weighing application, even tiny errors are not an option. You fear that temperature changes or slight off-axis loads will ruin your data and undermine your product's credibility.

A full-bridge circuit is the most accurate because it uses four active strain gauges. This setup maximizes sensitivity, provides complete temperature compensation, and cancels out unwanted signals like bending or torsion, leaving you with a pure, linear output that is easy to process.

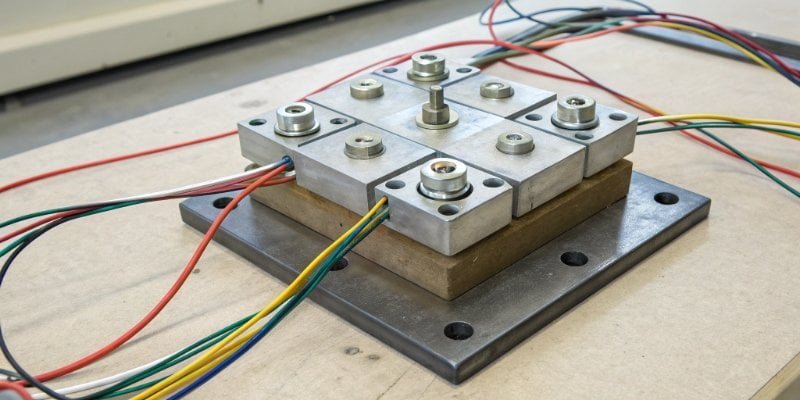

When accuracy is everything, the full-bridge10 is the only choice. This is the configuration all high-quality commercial load cells11 use. Here, all four resistors in the Wheatstone bridge are active strain gauges. Typically, two are mounted to measure tension, and two are mounted to measure compression. This arrangement provides several powerful benefits. First, it gives you the maximum possible output signal—four times that of a quarter-bridge. This higher signal is less susceptible to electrical noise12 and easier for your data acquisition system13 to read accurately.

Second, it provides perfect temperature compensation. Any change in temperature affects all four gauges equally, and the bridge circuit cancels it out completely. Most importantly, a full-bridge can be intelligently designed to isolate the exact force you want to measure. For example, in a load cell designed to measure tension, the gauges are placed so that if the load cell is accidentally bent or twisted, those forces are cancelled out, and the output signal still only reflects the pure tension. For our clients building high-precision lab balances or calibration-grade instruments14, we exclusively use full-bridge designs. It’s the gold standard for a reason.

| Feature | Quarter-Bridge | Half-Bridge | Full-Bridge |

|---|---|---|---|

| Active Gauges | 1 | 2 | 4 |

| Sensitivity | Baseline (1x) | Good (2x) | Excellent (4x) |

| Temp. Comp. | Poor (Requires dummy) | Good | Excellent |

| Bending Rejection | None | Limited | Excellent |

| Ideal For | Low-cost prototypes | Industrial scales, bending | High-precision load cells |

Conclusion

Choosing the right bridge is about matching the technology to the need. A quarter-bridge works for low-cost projects, a half-bridge offers a great balance for industry, and a full-bridge delivers ultimate precision.

-

Learn about the principles behind strain gauges and their applications in various industries. ↩

-

Learn about the Wheatstone bridge's role in enhancing measurement accuracy and temperature compensation. ↩

-

Explore the concept of mechanical strain and its significance in engineering applications. ↩

-

Understand how a dummy gauge helps in isolating true strain from temperature effects. ↩

-

Find out how a quarter-bridge configuration can be utilized in cost-effective strain measurement. ↩

-

Discover the importance of sensitivity in strain measurement and its impact on data quality. ↩

-

Discover various techniques for effective temperature compensation in sensor applications. ↩

-

Understand the benefits of half-bridge circuits for improved sensitivity and temperature compensation. ↩

-

Find out how strain gauges are utilized in various industrial applications for reliable measurements. ↩

-

Explore why full-bridge circuits are the gold standard for precision in strain measurement. ↩

-

Learn about load cells, their types, and their applications in weight measurement. ↩

-

Discover the impact of electrical noise on sensor readings and how to minimize it. ↩

-

Learn about data acquisition systems and their role in collecting and processing sensor data. ↩

-

Explore the significance of calibration-grade instruments in ensuring measurement accuracy. ↩

Comments (0)