Struggling to pick the right force sensor? Choosing incorrectly can cause system failure and inaccurate measurements, jeopardizing your projects. Let's clarify which one is right for your needs.

Load cells are standalone sensors offering very high accuracy, ideal for static weighing like on platform scales. Load pins integrate directly into machinery as a replacement pin, measuring shear force and excelling in rugged, heavy-duty applications like cranes where durability is key.

Now that you have a quick answer, you're probably wondering about the specifics. After 18 years in the industrial weighing business, I've seen countless projects succeed or fail based on this one choice. The details truly matter, especially when you are integrating weighing data into your software. Getting clean, reliable data starts with the right hardware.

Let's break down how their functions, pros and cons, applications, and installation truly set them apart. This knowledge will empower you to advise your customers and ensure your software performs flawlessly with the physical world.

How do load cells and load pins differ in functionality?

Confused about how these sensors actually measure force? Applying the wrong one for your customer's system is a recipe for bad data and technical support headaches. Let's look at their core mechanics.

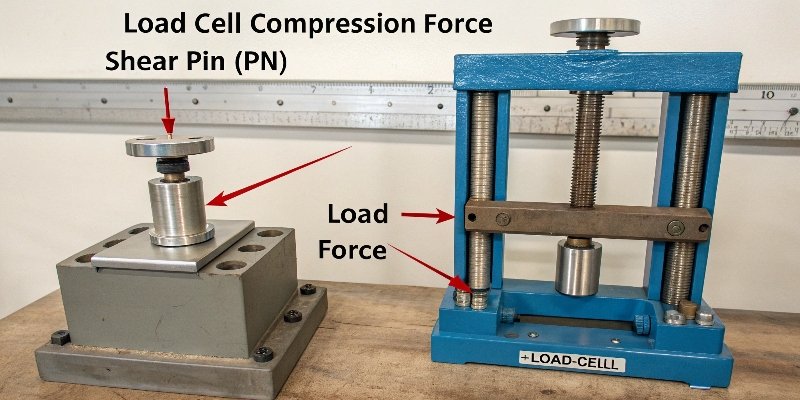

Load cells typically measure tension or compression forces along a single vertical axis. In contrast, load pins are designed to measure shear force, directly replacing structural pins in machinery and sensing the force exerted perpendicular to their axis.

The Principle of Load Cells

Load cells1 operate based on a simple principle: when you apply a force to a metal object, it deforms slightly. We attach sensitive strain gauges2 to a precisely machined metal body, called an elastic element. When a weight presses down on the load cell (compression) or pulls on it (tension), the element bends microscopically. This tiny change stretches or compresses the strain gauges, altering their electrical resistance. We measure this change in resistance and convert it into a weight reading. At Weigherps, our load cells are engineered for this one job: to provide an extremely accurate measurement of vertical force. This is perfect for a platform scale, where the goal is to measure the weight applied directly on top of it.

The Mechanics of Load Pins

Load pins3 work differently. Think of a load pin as a smart, instrumented version of a standard clevis pin or pivot pin already in a piece of machinery. Instead of measuring compression, it measures shear force4. Shear is the force that tries to 'cut' the pin in half. We embed strain gauges inside a small channel drilled through the center of the pin. As a load is lifted by a crane, for example, the force on the lifting sheave's axle tries to shear the pin. This causes a tiny deformation, which the internal strain gauges detect. This design is brilliant because it measures force without changing the machine's structure. I remember a client in port logistics who wanted to weigh containers as they were lifted. They initially considered a complex system with platform scales5. We showed them how replacing a single sheave pin on their crane with one of our custom load pins could achieve the same result with far less complexity, cost, and downtime.

What are the advantages and disadvantages of load cells versus load pins?

Worried about making the wrong trade-off? Choosing a sensor for one benefit might expose you to an unexpected weakness, leading to unhappy customers and integration challenges for your software.

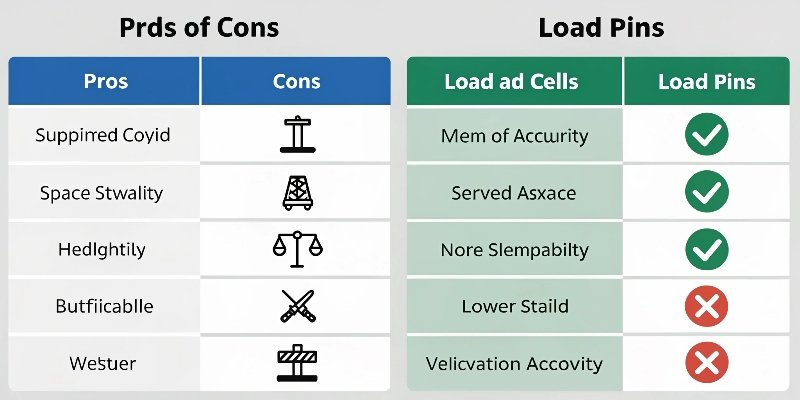

Load cells offer superior accuracy and are versatile for many static weighing setups. However, they can be sensitive to off-axis loads and require separate mounting. Load pins are extremely durable and space-efficient, but generally offer lower accuracy.

Choosing between a load cell and a load pin involves looking at the entire system. It's a balance between precision, durability, and ease of integration. Based on my experience helping hundreds of clients, the right choice depends entirely on the application's demands. For software vendors, understanding these trade-offs is key to specifying the right hardware for your data acquisition6 needs.

Here is a simple breakdown:

| Feature | Load Cells | Load Pins |

|---|---|---|

| Accuracy | Very High (up to 0.01% BFSL) | Good (typically 0.1% - 0.5% BFSL) |

| Installation | Requires dedicated brackets and careful alignment | Simple replacement of an existing mechanical pin |

| Durability | Good, but can be damaged by shock or side loads | Excellent; designed for harsh, high-impact environments |

| Footprint | Requires additional space for the mounting assembly | Zero additional footprint; integrates into structure |

| Sensitivity | Sensitive to off-axis and side forces | Primarily measures shear, less affected by other forces |

A high-accuracy load cell might be rated to 0.01% of its capacity. For a 10-ton load, that’s an error of just 1 kg. This is vital for commercial transactions. A load pin at 0.5% would have a 50 kg error for the same load, which is perfectly acceptable for overload prevention7 but not for selling goods by weight. On the other hand, the load pin is a solid piece of steel designed to be part of a machine. It's built to handle the shock and vibration of a mining truck or a construction crane, environments where a standard load cell would quickly fail without a very complex and expensive mounting structure.

In what applications are load cells preferred over load pins?

Unsure where each sensor truly shines? Misapplying them leads to poor performance and a wasted budget, reflecting poorly on the entire system, including your software. Let's explore ideal use cases.

Load cells are preferred in applications demanding high precision and certification for trade. This includes industrial platform scales, weighbridges, hopper and tank weighing systems, and laboratory balances where every gram counts.

When the primary goal is to answer the question, "Exactly how much does this weigh?", a load cell is almost always the answer. Their design is completely focused on delivering the most accurate and repeatable data possible, which is exactly what a high-performance software application needs.

Applications Requiring High Precision

For any application where weight is used for billing or tight process control, you need the accuracy of a load cell. Think about weighbridges8 that weigh trucks full of grain, or platform scales that price produce at a warehouse. In these "legal-for-trade" applications, accuracy is a legal requirement. We manufacture load cells that meet these stringent international standards like OIML. Similarly, in a food processing or chemical plant, batching systems rely on precise ingredient measurements from load cells installed under tanks and hoppers. A client of ours in the food industry was losing thousands a month from inconsistent mixing. By retrofitting their main ingredient hopper with a Weigherps load cell system, we gave them the precision they needed. Their losses stopped, and their product quality became consistent.

Controlled Environments and Clean Data

Load cells perform best in stable environments where forces are applied cleanly and vertically. While we build our products to be robust with IP68 protection, their core design is for controlled loading. This stable environment produces very clean, repeatable data. For you as a software provider, this is gold. Clean data means fewer exceptions to handle in your code, more reliable analytics, and happier customers. Our IoT-enabled scales, which are built on these precise load cells, are designed to feed this high-quality data directly into your ERP, MES, or custom applications, making integration seamless.

How do installation processes differ for load cells and load pins?

Overlooking installation complexity can blow your project budget and timeline. A choice that seems simple on paper can become a complicated field implementation. Let's compare their installation paths.

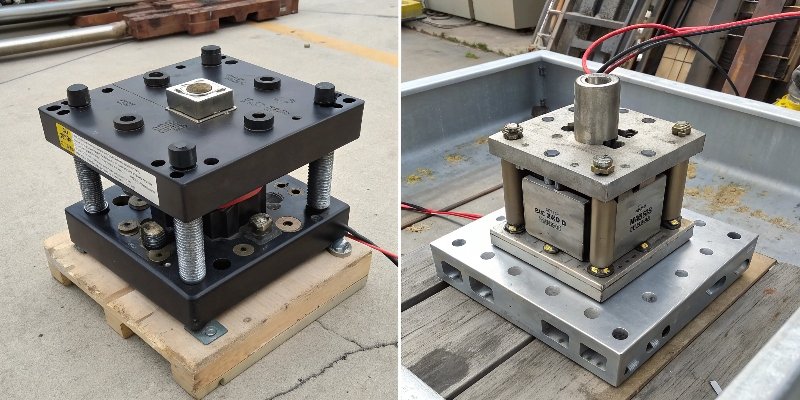

Load cell installation requires designing and building a dedicated mounting structure, ensuring perfect alignment, and protecting it from unwanted forces. Load pin installation is far simpler: remove the existing mechanical pin and slide the load pin in its place.

The difference in installation is one of the most practical distinctions between these two sensors. This factor directly impacts labor costs, downtime, and the engineering effort required for any weighing project.

The Load Cell Installation Journey

Installing a load cell is a true engineering task. First, you must design and build a mounting assembly. This includes top and bottom plates that are perfectly flat, rigid, and parallel. The load cell is then carefully bolted into this assembly. The most critical part is ensuring the force is applied perfectly through the cell's vertical axis. Any side load can cause inaccurate readings and even permanent damage. Because of this, we often have to add check rods or stays to prevent the weighed structure, like a large tank, from shifting. Finally, overload stops must be installed to protect the cell from accidental drops or over-filling. While we provide extensive documentation and technical support, the physical installation requires skilled technicians and significant mechanical work.

The Load Pin Installation Process

Installing a load pin is, by comparison, remarkably simple. It’s a job for a maintenance team, not a team of engineers. First, we work with you to get the exact dimensions of the existing structural pin in your customer's machinery. We then manufacture a load pin that is a perfect mechanical twin. On-site, the process is straightforward: knock out the old pin, and slide the new load pin into the same spot. It is secured with the same components, like cotter pins or retaining plates. The only addition is a small anti-rotation bracket to keep the pin correctly oriented. After that, you just connect the cable. This simplicity makes load pins the ideal choice for retrofitting weighing capabilities onto existing heavy machinery with minimal downtime.

Conclusion

In short, choose load cells for high-precision weighing in controlled setups. Select durable, space-saving load pins for monitoring force and overload in rugged, heavy machinery.

- Explore this resource to understand the mechanics and applications of load cells for accurate measurements. ↩

- Explore the technology behind strain gauges and their role in providing accurate weight readings. ↩

- Learn about load pins and how they can simplify force measurement in machinery. ↩

- Gain insights into shear force measurement and its relevance in engineering applications. ↩

- Explore the functionality of platform scales and their reliance on load cells for accuracy. ↩

- Understand the concept of data acquisition and its importance in weighing applications. ↩

- Learn how load pins help prevent overload in machinery and enhance safety. ↩

- Learn about weighbridges and their critical role in commercial transactions and logistics. ↩

Comments (0)