Struggling to budget for a new lab balance? The prices seem to be all over the place, making it hard to know if you're getting a fair deal.

The price of a lab balance depends on its type and precision. Basic precision balances range from $500 to $3,000. High-precision analytical balances cost between $3,000 and $13,000, while ultra-sensitive microbalances can range from $13,000 up to $60,000 or more.

I've been in the weighing industry for nearly two decades. I've helped countless clients navigate the complexities of purchasing weighing equipment. The sticker shock is real, but understanding what drives the price is the key to making a smart investment. It's not just about buying a scale; it's about buying the right tool for the job that will serve you reliably for years. Let's break down why these costs vary and what you truly get for your money.

Why do prices for laboratory balances vary so much?

Confused by the massive price gap between two similar-looking balances? You aren't alone. This variation often leaves buyers wondering what they're actually paying for.

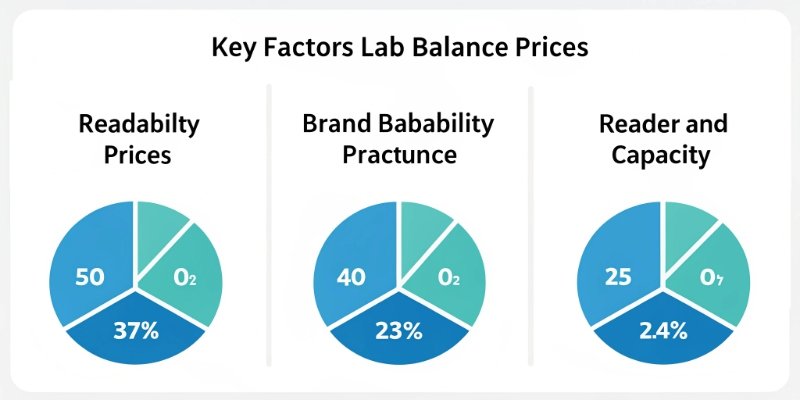

Prices vary due to differences in readability, capacity, internal technology, and brand reputation. A balance with higher precision and more advanced features will always command a higher price than a basic model. International brands also typically carry a 30-50% price premium over domestic manufacturers.

When we build scales, every component choice impacts the final cost and performance. The price of a lab balance1 is a direct reflection of its internal engineering and intended application. Think of it like buying a car. A basic sedan and a high-performance sports car both have four wheels and an engine, but the technology under the hood is worlds apart. The same principle applies here. The main drivers of price are precision (readability2), the brand name, the internal weighing mechanism3, and any additional features like data output4 or compliance software5. A balance designed for simple classroom experiments has very different components than one used for pharmaceutical research, and that is directly reflected in the final cost.

Key Price Factors

| Factor | Low-Cost Balance Impact | High-Cost Balance Impact |

|---|---|---|

| Readability | Lower precision (e.g., 0.1g - 0.01g) | Higher precision (e.g., 0.0001g or better) |

| Brand | Often domestic or lesser-known brands | Established international brands (e.g., Mettler-Toledo) |

| Technology | Simpler strain gauge load cells | High-precision electromagnetic force restoration (EMFR) |

| Features | Basic weighing functions | Advanced features, data ports, compliance software |

How does the cost of an analytical balance compare to a precision balance?

You know you need accuracy, but is a precision balance enough? Or do you need to invest in a more expensive analytical balance for your work?

An analytical balance typically costs significantly more than a precision balance. Expect to pay from $3,000 for an entry-level analytical model, whereas a good precision balance can be found for as low as $500. This price gap reflects the higher level of engineering required.

The core difference is the level of detail they can measure. Precision balances are the workhorses of the lab, great for general tasks. Analytical balances are specialists, designed for when every fraction of a milligram counts. We see this with our clients all the time. A food production client might use a precision balance for recipe formulation, which is perfectly adequate. But a pharmaceutical client developing a new drug must use an analytical balance to ensure dosage accuracy, where even a tiny error could have huge consequences. The higher cost of the analytical balance is an investment in risk reduction and quality assurance.

Cost and Feature Breakdown

The primary reason for the price difference lies in two areas: readability and construction.

- Readability: Precision balances typically measure to 0.1g, 0.01g, or 0.001g. Analytical balances offer much finer readability, usually to 0.0001g (four decimal places) or even smaller. This requires a more sensitive and sophisticated weighing sensor, often an Electromagnetic Force Restoration (EMFR) cell, which is more expensive to produce.

- Construction: Analytical balances almost always include a draft shield. This glass or plastic enclosure protects the highly sensitive weighing pan from air currents, dust, and even the operator's breath, all of which can affect the measurement. This adds to the material and manufacturing cost.

If your budget is limited, a high-quality precision balance ($500 - $3,000) is excellent for most routine weighing. However, for serious research, pharmaceutical compounding, or quality control6 testing, the investment in an analytical balance ($3,000 - $13,000) is non-negotiable.

Is it worth paying more for a lab balance with higher readability?

Seeing a high price for better readability makes you wonder, is it overkill? Will you actually use that extra decimal place, or are you just paying for a feature you don't need?

Yes, it is absolutely worth paying for higher readability if your application demands it. The cost of a failed batch, an inaccurate formulation, or a rejected scientific paper far outweighs the higher initial price of a more precise balance. It's an investment in accuracy and reliability.

I always advise my clients to match the tool to the task. Using a balance with insufficient readability is a common but costly mistake. Imagine you are working with a potent chemical where a 1mg dose is effective, but a 1.2mg dose is toxic. If your balance only reads to two decimal places (0.01g), you cannot accurately measure 1mg (0.001g). You're essentially working blind. The extra cost for a balance with 0.001g or 0.0001g readability isn't a luxury; it's a fundamental requirement for safety and success. Paying for higher readability is buying certainty.

When to Invest in Higher Readability

The decision comes down to your tolerance for error. Here’s how to think about it:

- Regulatory and Quality Standards: Industries like pharmaceuticals, environmental testing, and material science have strict standards (e.g., USP, GLP/GMP). These regulations often mandate a specific level of readability to ensure valid results. In this case, the choice is made for you.

- Cost of Materials: If you are working with very expensive or rare substances, wasting material due to inaccurate measurements can become very costly over time. A more precise balance minimizes waste and saves money in the long run.

- Compounding and Formulation: When creating chemical mixtures or pharmaceutical compounds, the ratio of ingredients is critical. Higher readability ensures that these ratios are precise, leading to consistent and effective end products.

For simple buffer preparation or weighing out large, non-critical samples, a basic balance is fine. But for anything involving small sample masses, strict tolerances, or high-consequence applications, the investment in higher readability provides critical peace of mind and data integrity.

What are the long-term costs to consider when purchasing a lab balance?

That low upfront price on a budget balance looks tempting. But are you setting yourself up for hidden costs and headaches down the road that will erase those initial savings?

Beyond the initial purchase, you must budget for calibration, servicing, potential repairs, and downtime. A cheaper, less reliable balance may incur higher long-term costs through more frequent servicing and an earlier need for replacement, ultimately costing more than a quality unit.

As a manufacturer, we build products designed to last. We know that the total cost of ownership7 is what truly matters to our clients. A balance is not a one-time purchase; it's a piece of critical infrastructure for your lab. A low-quality balance that fails can halt production or research, and the cost of that downtime can quickly dwarf the initial price of the equipment. That's why our quality control department tests every single unit for weight, battery, and software performance before it ever leaves our factory. Investing in a reliable product with a solid warranty and support network is the most effective way to control long-term costs.

Total Cost of Ownership (TCO)

Don't just look at the sticker price. Consider these factors over the balance's entire lifespan:

- Calibration: All balances drift over time and require regular calibration8 to ensure accuracy. This is a recurring service cost. Professional calibration can cost from $100 to $300 per visit, depending on the type of balance and level of certification required.

- Maintenance and Repairs: Higher-quality balances from reputable manufacturers are built with more durable components, leading to fewer breakdowns. Our products, for example, come with a 12-month warranty, but they are designed to perform reliably for years beyond that. A cheap balance might fail outside of its short warranty period, leaving you with a hefty repair bill or the need for a full replacement.

- Downtime: This is the biggest hidden cost. If your balance fails, how long does it take for your supplier's after-sales team to respond? Every hour your balance is out of commission can mean lost revenue or delayed projects. Choose a partner known for responsive technical support.

Ultimately, a slightly higher initial investment in a well-built balance from a trusted manufacturer often results in a lower total cost of ownership.

Conclusion

Choosing the right lab balance involves matching its price and precision to your specific needs. From basic models to high-tech analytical units, understanding the cost drivers ensures a smart, long-term investment.

-

Understanding lab balances is crucial for making informed purchasing decisions. ↩

-

Understanding readability helps in selecting the right balance for your tasks. ↩

-

Different mechanisms affect performance; learn which is best for your needs. ↩

-

Data output features can enhance your lab's efficiency; find out more. ↩

-

Compliance software ensures regulatory adherence; learn how it benefits your lab. ↩

-

Quality control relies on accurate measurements; find out how balances contribute. ↩

-

Evaluating TCO helps in making a financially sound investment. ↩

-

Regular calibration is vital for accuracy; learn about its importance. ↩

Comments (0)