When accuracy and reliability are demanded in weighing, few things matter more than using the right material for commercial load cells.

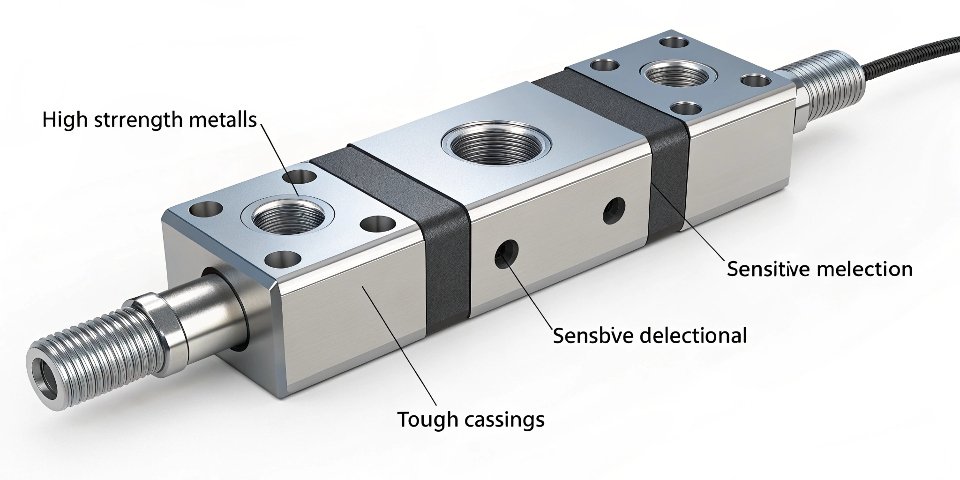

Commercial load cells are usually made from high-strength metals for their structural parts, sensitive materials for detection, and sealed with tough outer casings to ensure performance and durability in real-world conditions.

I have found that understanding the material behind each load cell helps when you need to choose the right one for your project. Most clients want to know what exactly they are buying. If you need to guarantee measurement accuracy1, long-term stability2, and resistance to various industrial environments3, knowing these details matters. Let’s take a closer look.

What material are load cells made of?

You may be frustrated by choices on the market, but most load cells use specific metals and materials to ensure high accuracy and a long service life.

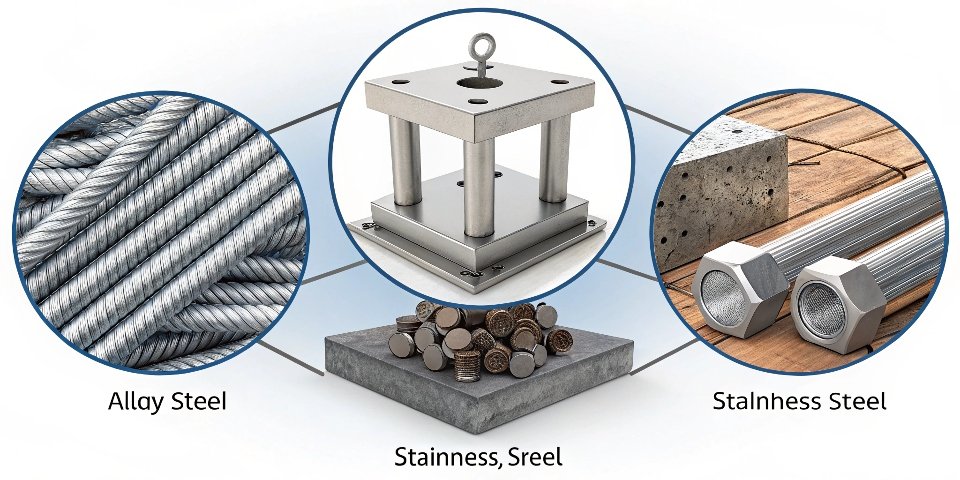

The main materials used in commercial load cells are alloy steel, stainless steel, and aluminum. Manufacturers choose them primarily for their high strength, resistance to corrosion, and excellent performance in repeated load cycles.

When I visit our workshop, the variety of metals used always stands out. Alloy steel load cells offer outstanding strength and cost-effectiveness. Stainless steel is selected for its corrosion resistance, making it good for humid or harsh environments. Aluminum, the lightest of the three, is used when weight saving is critical, like for platform scales. All metals are processed with surface treatments to fight oxidation and wear. Here’s a quick table for reference:

| Material | Advantages | Typical Application |

|---|---|---|

| Alloy Steel | High strength, low cost | Truck scales, platform scales |

| Stainless Steel | Corrosion resistance, durability | Food/pharma industry, outdoors |

| Aluminum | Lightweight, easy machining | Bench scales, OEM solutions |

Adding to that, surface finishes such as nickel plating or anodizing further protect these metals. This way, each load cell can deliver stable readings for years.

What does a load cell consist of?

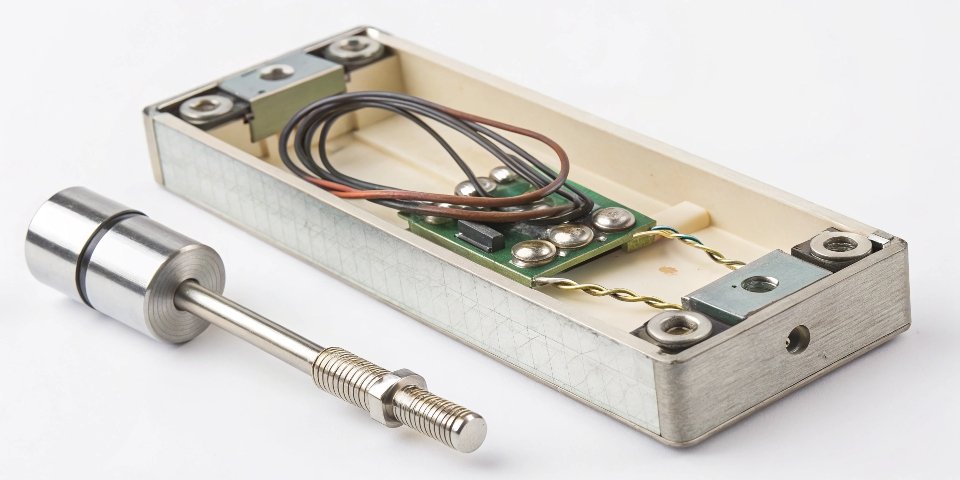

A load cell is not just one block of metal. It’s built up from several important parts to measure force accurately.

A typical commercial load cell consists of a metal elastic body, strain gauge sensors, wiring, and a protective casing. The metal body bears the load, while the sensitive strain gauges detect deformation and convert it into an electrical signal.

In each load cell I have worked on, the elastic body—or force-bearing element—takes the main job. This is where the load is actually applied. The most sensitive part, the strain gauge, is bonded to this metal, often with special adhesives. The wiring then routes the small voltage changes to an amplifier or controller. Encasing all these is a protective housing, usually sealed to IP65 or higher. This blocks out moisture, dust, and other contaminants. Here’s a quick breakdown:

Key Parts of a Commercial Load Cell

| Part Name | Description | Main Material |

|---|---|---|

| Elastic Body | Core structure, deforms under load | Alloy steel, stainless steel4, aluminum |

| Strain Gauge | Senses strain, converts mechanical force to electrical signal | Metal foil, semiconductor |

| Wiring | Carries electrical signal | Copper wires |

| Casing | Protects internal components from environment | Stainless steel, alloy steel5, plastic |

All parts must work together tightly for the load cell to give an accurate, repeatable reading.

How is a load cell made?

If you ever wondered how load cells turn from raw material into precision devices, the answer is careful shaping, assembly, and testing.

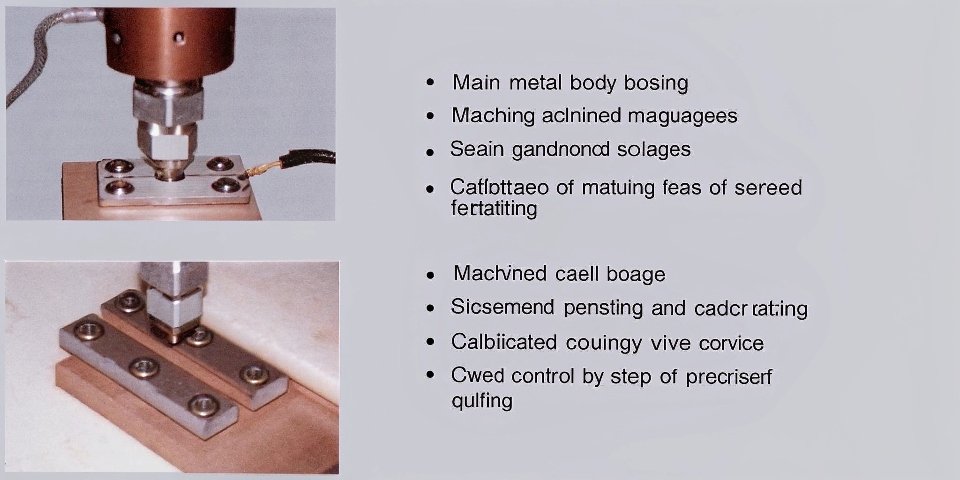

Load cells are manufactured by machining the main metal body, precisely bonding strain gauges, assembling other components, sealing the device, and then rigorously calibrating and testing every unit for accuracy.

In my experience, the process starts with choosing the right grade of metal and machining it into a shape that can flex just enough to measure load but not bend permanently. To this body, technicians attach strain gauges. This step needs clean rooms and controlled humidity, since any contamination may ruin performance. Then, wires are soldered, and the gauge is covered, usually with a silicone gel. A tough casing goes on last, followed by laser welding or gluing to seal the load cell. Before it ships, we check every unit for drift, accuracy, and response time. Here is how the steps line up:

Load Cell Manufacturing Steps

| Step | Key Actions |

|---|---|

| Metal Preparation | Cut, machine, and finish the main body |

| Strain Gauge Bonding | Clean, bond, and position the strain gauge |

| Wiring | Solder wiring for electrical output |

| Sealing | Cover with protective housing, seal against ingress |

| Calibration | Test performance under known weights, adjust output |

| Final Inspection | Check appearance, protection level, data consistency |

Making load cells to tight specs ensures they keep working for years—no matter how tough the job site.

What are the four types of load cells?

Choosing the right type of load cell is crucial, but what types are there, and how do they differ?

The four most common types of commercial load cells are strain gauge load cells, hydraulic load cells, pneumatic load cells, and capacitive load cells. Each type measures force differently and serves distinct industrial needs.

In my years advising clients, I have seen that each type of load cell fits best in certain environments:

Types of Load Cells Explained

Strain Gauge Load Cells

The most widely used. They rely on the change in electrical resistance of metal strain gauges stuck to a metal body. Small, robust, and suitable for many tasks, from silos to truck scales.

Hydraulic Load Cells

Use changes in fluid pressure to measure weight. No need for power to measure, so they work well in hazardous or remote areas, but are bulkier and more expensive.

Pneumatic Load Cells

Similar to hydraulic but use air or gas instead of liquid. They are good for cleanrooms or industries where contamination is not allowed, but they require a regulated air supply.

Capacitive Load Cells

Detect changes in capacitance as load stretches a metal diaphragm. These are usually for high-precision lab instruments, but sensitive to vibration and temperature.

| Load Cell Type | Working Principle | Best Use Case |

|---|---|---|

| Strain Gauge | Electrical resistance change | General industrial, OEM |

| Hydraulic | Fluid pressure | Dangerous or remote sites |

| Pneumatic | Air pressure | Clean, contamination-free |

| Capacitive | Capacitance change | Laboratory, precision work |

Selecting the right type depends on your needs for precision, ruggedness, and the working environment.

Conclusion

The right material, structure, and type of commercial load cell will lead to better accuracy and long-lasting performance in any industrial application.

-

Understand the key factors that affect the accuracy of load cells in various applications. ↩

-

Explore methods and materials that ensure long-term stability in load cell performance. ↩

-

Learn about the features that allow load cells to withstand harsh industrial conditions. ↩

-

Explore the corrosion resistance and durability of stainless steel in load cell applications. ↩

-

Discover why alloy steel is a popular choice for load cells and its benefits in industrial applications. ↩

[…] Weighing semiconductor components2 […]