Struggling to understand how a simple platform can measure massive weights with precision? This complexity can make choosing the right equipment feel like a gamble for your business operations.

The core mechanism of a weighing machine involves a sensor, typically a load cell, that converts the physical force of weight into an electrical signal. This signal is then processed, converted into a digital value by a microprocessor, and displayed as a readable weight measurement on a screen.

Here at Weigherps, we’ve spent 18 years building these machines from the ground up. I’ve seen firsthand how these components work together. It’s not magic, but a precise science. Understanding this mechanism is the first step for any purchasing manager or technical director aiming to invest in reliable equipment. This knowledge helps you ask the right questions and ensure you get a system that truly meets your needs. Let’s break down how it all comes together to deliver the accuracy your business depends on.

How do industrial weighing machines achieve precision and accuracy in measurements?

Inaccurate weights can lead to lost profits and compliance failures. You need measurements you can trust, but achieving consistent precision in an industrial setting is a major challenge.

Industrial weighing machines achieve high precision through a combination of sensitive load cells, advanced signal processing to filter out noise and environmental interference, and a robust mechanical structure that ensures force is applied uniformly.

In my experience, precision isn’t about a single "magic" component. It’s about how the entire system works in harmony. A great load cell1 is useless if the machine’s software can’t properly interpret its signal. That’s why we focus on the entire process. The microprocessor2 is key. It doesn’t just read the signal; it cleans it up. It runs algorithms to compensate for temperature changes or slight vibrations that could throw off the reading. We also designed the physical scale to direct all the weight onto the sensors correctly. It’s this total system approach that separates a basic scale from a truly precise industrial instrument. We have seen how a well-integrated system can maintain accuracy to within 0.1% or better, even in tough factory conditions.

What are the core mechanical and electronic components of commercial weighing systems?

Opening a weighing system can reveal a confusing web of wires and parts. It’s hard to assess quality when you don’t know what you’re looking for or what each part does.

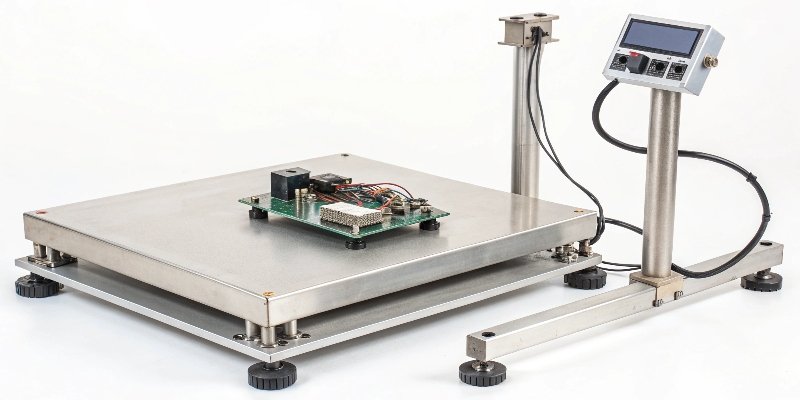

The core components are the load cell (sensor), an Analog-to-Digital Converter (ADC), a microprocessor (the "brain"), and a display. Mechanically, the weighing platform and its supporting frame are essential for directing force onto the load cells.

Let’s look at how these pieces fit together. Think of it as a chain of command. The platform and frame are the foundation, making sure the object’s weight is properly supported. This physical force is then measured by the load cells. From there, the electronics take over. As an ODM manufacturer for global brands, we pay close attention to the quality of each link in this chain. A weak link anywhere compromises the whole system. Below is a simple breakdown of each component’s role.

| Component | Type | Function |

|---|---|---|

| Weighing Platform | Mechanical | Supports the object being weighed and transfers the force. |

| Load Cell | Electro-mechanical | Converts the physical force of weight into a tiny electrical signal. |

| A/D Converter | Electronic | Changes the analog electrical signal from the load cell into a digital format. |

| Microprocessor | Electronic | Processes the digital data, applies calibration3, and calculates the final weight. |

| Display / Interface | Electronic | Shows the final weight to the user and allows for system interaction. |

Understanding this structure helps you, as a buyer, to ask better questions about the quality of the ADC or the processing power of the microprocessor, not just the capacity of the scale.

How do load cells function within modern digital weighing machines?

Have you ever wondered how a solid piece of metal can detect a tiny change in weight? This core technology can seem like a black box, making it difficult to judge its quality.

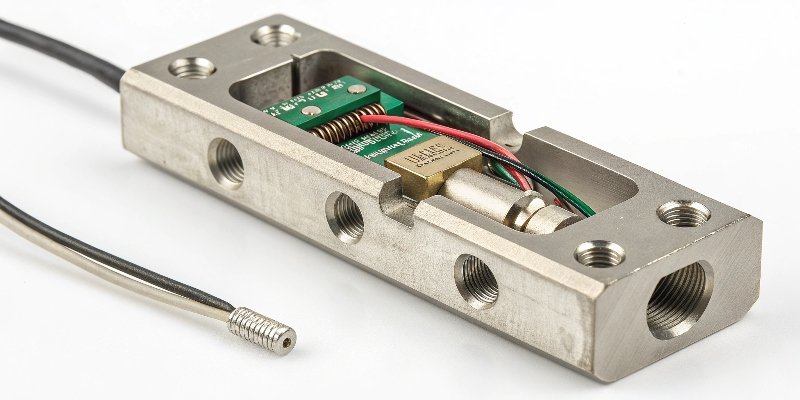

A load cell works by measuring deformation. When weight is applied, a metal element inside the cell bends slightly. This strain is detected by attached strain gauges, which change their electrical resistance. This change is then measured to calculate the weight.

The most common type we use is the strain gauge4 load cell. The principle behind it is beautifully simple: Hooke’s Law. It states that the force needed to stretch or compress a spring is directly proportional to the distance. In our case, the "spring" is a precisely engineered piece of steel or aluminum. Bonded to this metal body are tiny, foil-like grids called strain gauges. When the metal flexes under weight, these grids stretch or compress, changing their electrical resistance. We arrange multiple strain gauges into a configuration called a Wheatstone bridge5. This circuit is extremely sensitive to these tiny resistance changes, allowing it to produce a measurable voltage output that is directly proportional to the weight. This output is the raw electrical signal that begins the measurement process. We carefully select load cells based on the application, whether it requires high precision for labs or rugged durability for outdoor truck scales.

What influence does calibration have on the performance of enterprise-grade weighing equipment?

Your new scale works perfectly, but over time, readings start to drift. This gradual inaccuracy can silently cost your company money and create major compliance headaches if left unchecked.

Calibration is the single most critical factor for maintaining long-term accuracy. It adjusts the scale’s internal parameters to match a known, certified weight standard, correcting for any sensor drift or environmental changes and ensuring reliable performance.

Think of calibration as tuning a musical instrument. Even the best-made guitar will go out of tune over time. A weighing scale is no different. Factors like temperature fluctuations, continuous use, and tiny mechanical shifts cause its readings to "drift." Calibration resets the scale back to its correct state. During our quality control process, every single unit we ship is calibrated. Our technicians use a set of certified standard weights. They place a known weight on the scale and then adjust the software parameters until the scale’s reading perfectly matches the standard weight. This process is repeated at several points across the scale’s capacity to ensure linearity—meaning it’s accurate for both light and heavy loads. For any enterprise, regular re-calibration isn’t optional; it’s a fundamental part of quality assurance. It’s the only way to guarantee your weighing data is trustworthy for production, sales, and legal compliance.

Conclusion

Understanding the mechanism of weighing machines, from sensors to calibration, empowers you to choose reliable equipment. This ensures the accuracy and efficiency your business needs to grow and succeed.

-

Explore this link to understand the fundamental role of load cells in accurate weight measurement. ↩

-

Discover how microprocessors process data to ensure reliable weight readings. ↩

-

Find out how regular calibration maintains accuracy and compliance in weighing systems. ↩

-

Delve into the technology behind strain gauges and their role in weight detection. ↩

-

Explore the Wheatstone bridge configuration that enhances sensitivity in weight measurement. ↩

[…] electrical resistance. The change is incredibly small, so we use a sensitive circuit called a Wheatstone bridge4 to detect it as a tiny voltage signal. This analog signal is then amplified and converted into a […]